Composite rotor vacuum pump

A compound rotor and vacuum pump technology, applied in the direction of pumps, pump components, pump combinations for elastic fluid rotary piston type/swing piston type, etc., can solve problems such as high fuel consumption, complex structure, and large gear transmission noise, and achieve safety High performance, simplified transmission structure, and noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

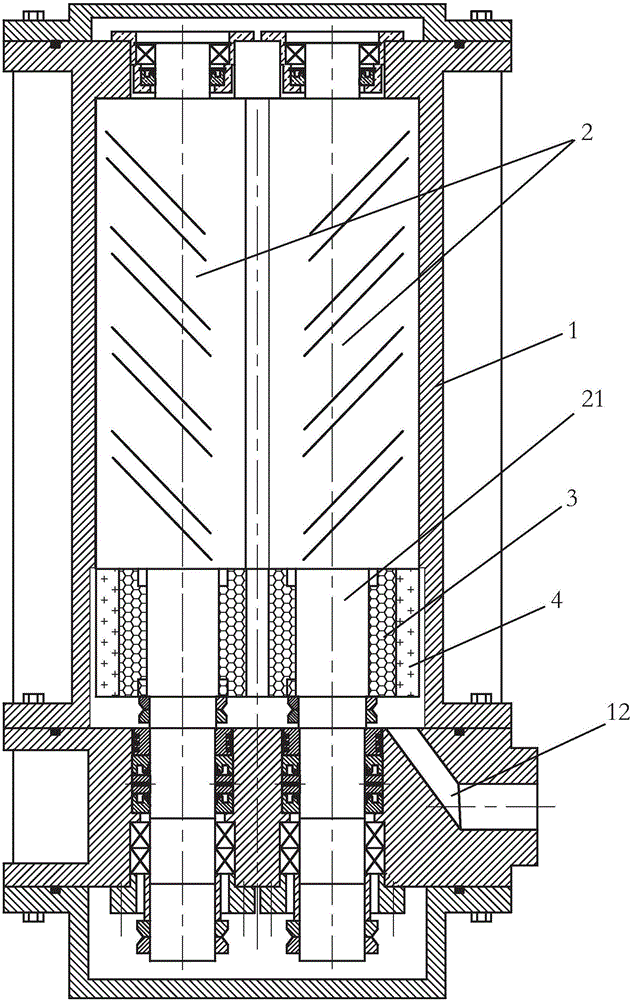

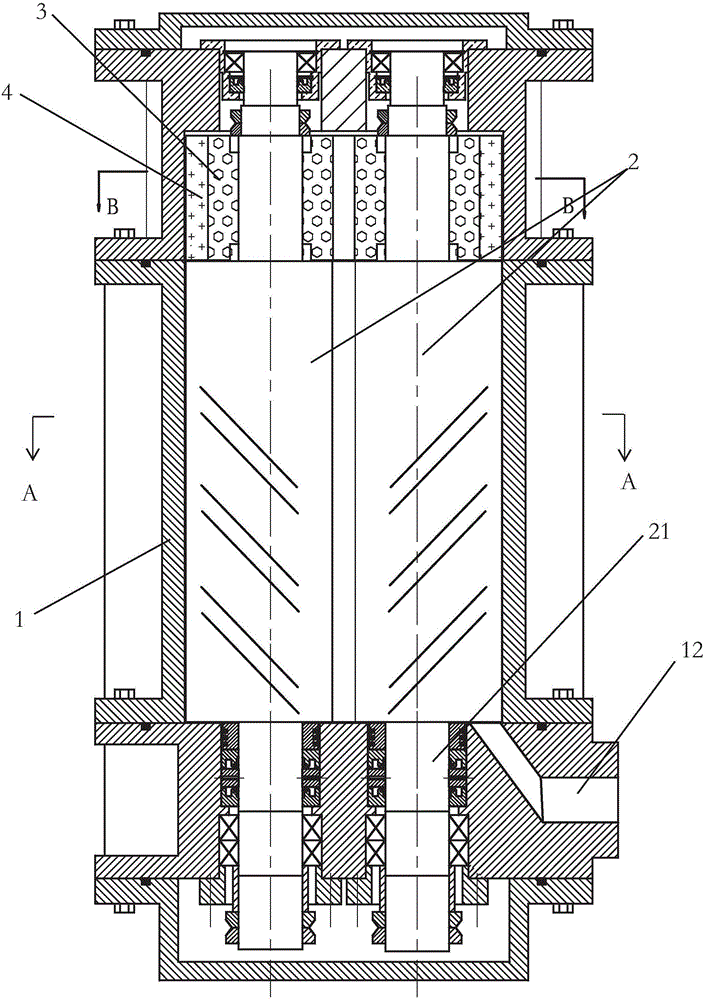

[0039] Such as Figure 1-4 Shown is a schematic structural view of the present invention applied to a screw dry vacuum pump; the specific technical solution is as described above. I won't repeat them here.

[0040] It works as follows:

[0041] The motor stator is energized, and the motor rotor on the rotor in the pump cavity forms an induced electromotive force after power is applied. Since the motor stator is a common one, the frequency of the two motor rotors is the same. The motor rotor will rotate at the same frequency, and drive the rotor in the pump chamber to rotate at high speed and reverse synchronously, which meets the requirements of the vacuum pump rotor shaft synchronously and mutually reversely rotating, replacing the traditional motor, coupling, gear set .

[0042] Thus, the traditional motor drives the gear set to drive the complex structure of the pump chamber rotor to rotate. The complexity of the structure is greatly reduced, and the manufacturing cost ...

Embodiment 2

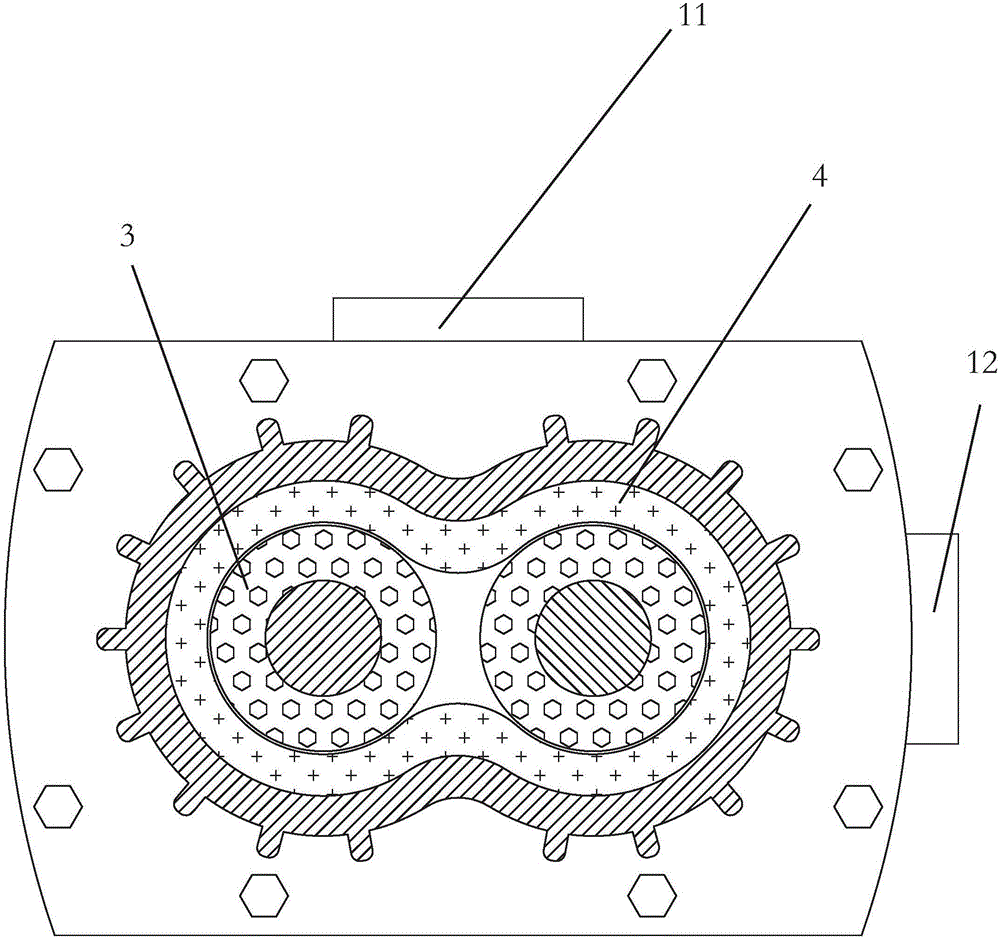

[0045] Such as Figure 5-8 Shown is a schematic diagram of the structure of the application of the present invention to a Roots vacuum pump. Since it is also driven by double rotors, it is also applicable to the technical solution of the present invention. The specific technical solution is as described above, and will not be repeated here;

[0046] Applying the present invention to a Roots vacuum pump, its Roots rotor can be a two-lobe Roots rotor, a three-lobe or a four-lobe Roots rotor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com