Silencer of range hood

A range hood and muffler technology, which is applied in the direction of oil fume removal, machines/engines, mechanical equipment, etc., can solve the problems of not very obvious noise reduction effect and reduced exhaust air volume of range hoods, and achieve good noise reduction effect and reduce noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

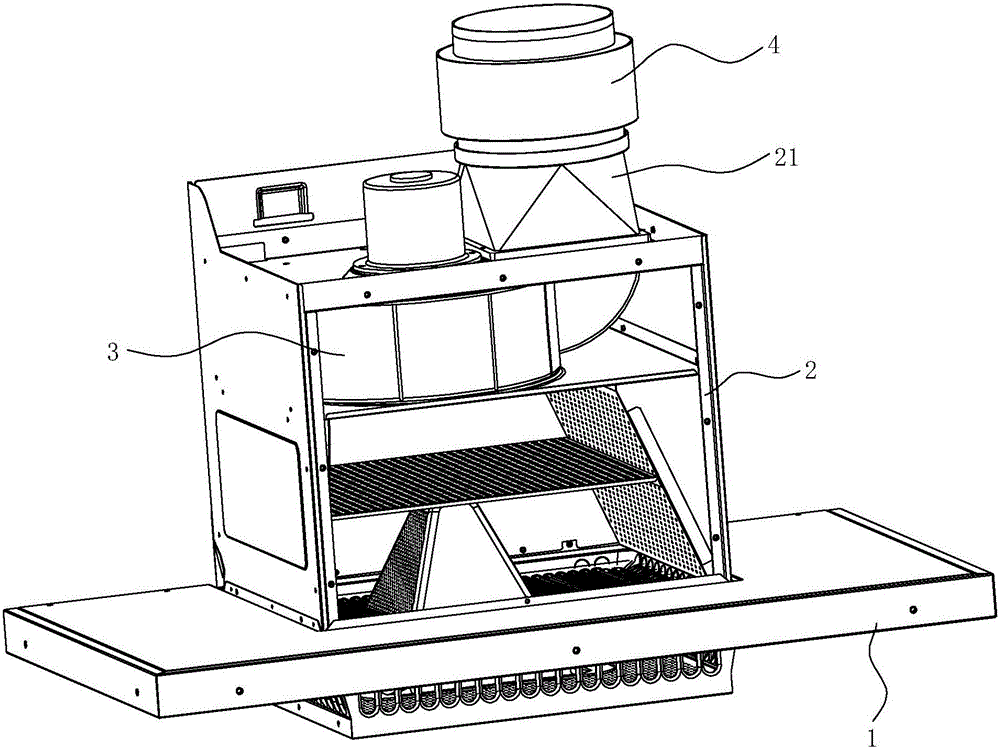

[0024] see figure 1 , a range hood, comprising a smoke collection hood 1, a box 2 arranged above the smoke collection hood 1, a fan 3 is arranged in the box 2. An air inlet is provided on the fume collecting hood 1, so that the fan 3 in the box body 2 can suck the oil fume into the box body 2 through the air inlet 11 and discharge it to the public flue.

[0025] The top of the box body 2 is provided with an air outlet hood 21 , which is used to discharge oil fumes in the box body 2 to the outside of the box body 2 . The outlet of the air outlet cover 21 is provided with a muffler 4 for solving the problem of high noise at the outlet.

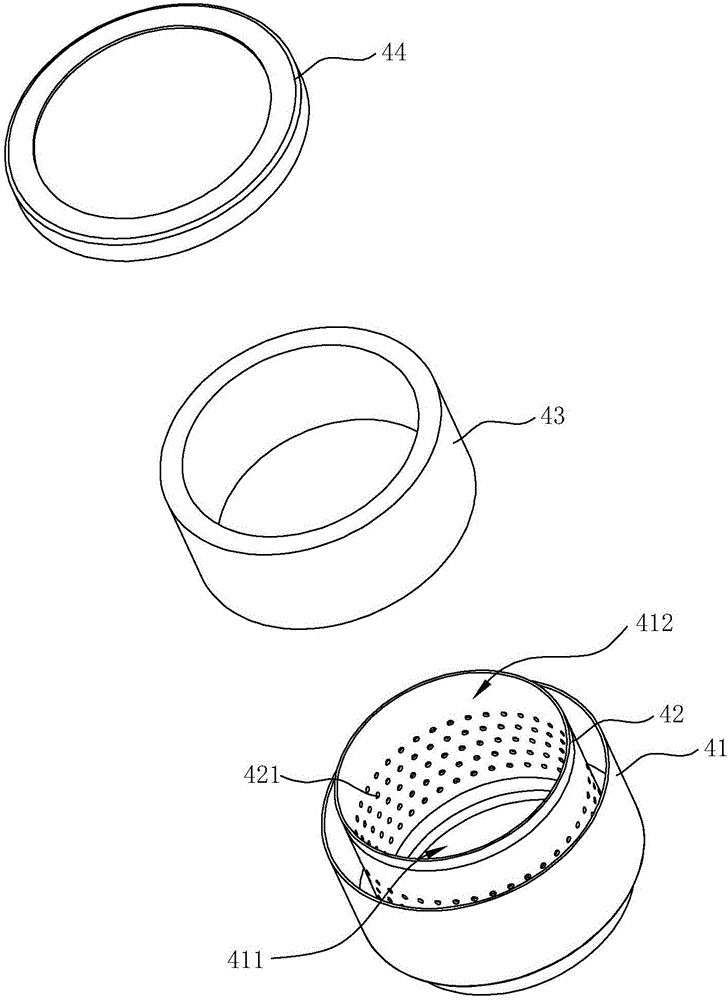

[0026] see figure 2 , The muffler 4 comprises a muffler shell 41, a sound-absorbing wall 42 arranged in the muffler shell 41, a sound-absorbing cotton 43 arranged between the sound-absorbing wall 42 and the muffler shell 41, and an upper cover 44 arranged at the top of the muffler shell 41. The muffler shell 41 is hollow columnar, and the mu...

Embodiment 2

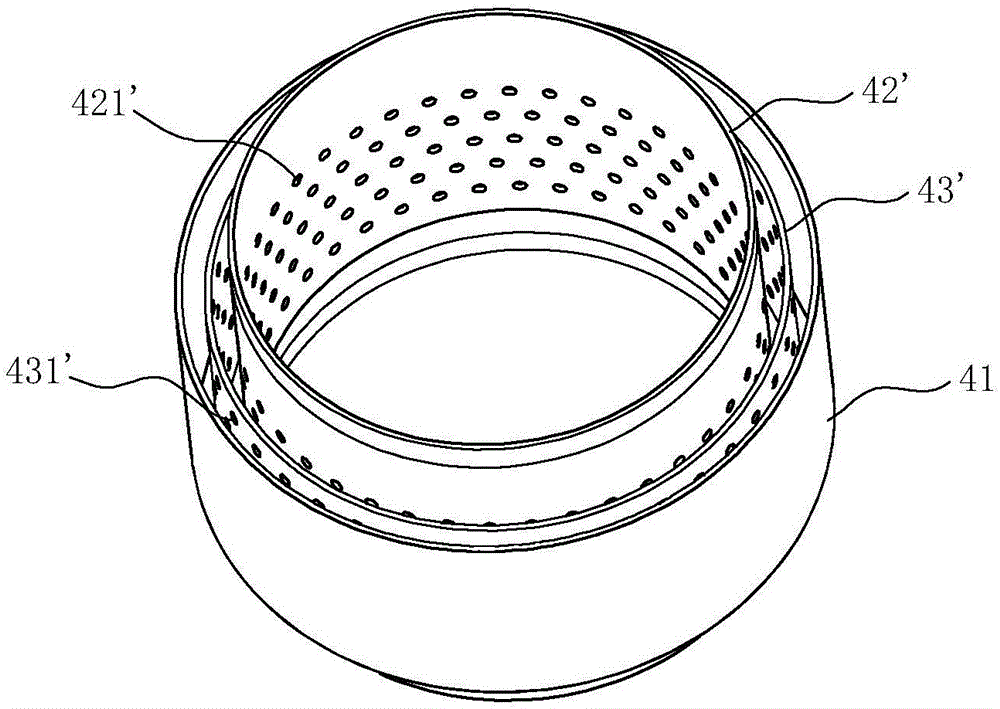

[0028] see image 3 and Figure 4 , In this embodiment, the difference from the first embodiment above is that a double-layer cavity micropore is used instead of the above-mentioned solution of micropore + sound-absorbing cotton. The muffler 4' comprises a muffler housing 41, a muffler wall and an upper cover 44, and the muffler wall includes a first muffler wall 42' arranged in the muffler housing 41', and a wall mounted between the muffler housing 41 and the first muffler wall 42'. Between the second anechoic wall 43', image 3 Hidden loam cake 44 in.

[0029] Wherein, both the first sound-absorbing wall 42' and the second sound-absorbing wall 43' are annular, such as a ring, or irregular, such as petals. The upper cover 44 closes the top of the gap between the muffler housing 41 and the first muffler wall 42 ′, while the bottom of the muffler housing 41 extends radially inward to the first muffler wall 42 ′ to close the muffler housing 41 and the first muffler housing 41...

Embodiment 3

[0032] see Figure 5 and Figure 6 , in this embodiment, the muffler 4" includes a hollow muffler shell 41, and the muffler 41 is arranged with a first partition 42" and a second partition 43" at intervals along the axial direction, and the first partition 42" and the second partition The plate 43" extends radially, thereby dividing the space in the muffler housing 41 into the direction from the oil fume flow inlet 411 provided at the bottom to the oil fume flow outlet 412 provided at the top ( Figure 6 Viewed from left to right, installed from bottom to top) three chambers, that is, the first chamber 44 ″ between the bottom of the muffler shell 41 and the first partition 42 ″, the first partition 42 ″ and the second The second chamber 45" between the partitions 43", and the second partition 43" and the third chamber 46" on the top of the muffler housing 41. An outlet partition 413 is provided at the outlet 412 of the oil fume flow. The outlet partition 413 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com