A double-tightened unilateral bolt connection

A technology of unilateral bolts and connectors, applied in the direction of connecting components, threaded fasteners, locking fasteners, etc., can solve the problems of small contact surface, affecting the stability of the connection structure, easy to loosen, etc., to achieve increased The effect of fastening the contact surface, low cost, and not easy to loosen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

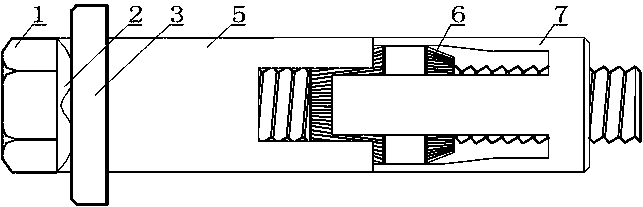

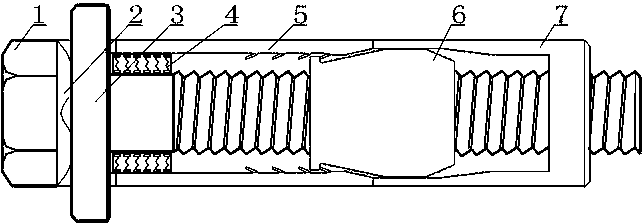

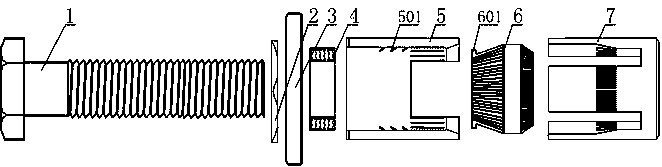

[0026] Such as Figure 1 ~ Figure 4As shown, a double-fastened unilateral bolt connector includes a positioning bolt 1, a rigid washer 3, a first positioning cylinder 5, a bidirectional cone head 6 and a second positioning cylinder 7, wherein the rigid washer 3, the first positioning cylinder The cylinder 5, the bidirectional cone head 6 and the second positioning cylinder 7 are all pierced on the positioning bolt 1, and the four are arranged sequentially from the end of the positioning bolt 1 with the bolt head to the other end of the positioning bolt 1. In this embodiment, both the rigid washer 3 and the first positioning cylinder 5 are in clearance fit with the screw of the positioning bolt 1 , and the inner diameter of the rigid washer 3 is smaller than the outer diameter of the first positioning cylinder 5 . The end of the second positioning cylinder 7 in this embodiment away from the bolt head is provided with a sealing plate, and the sealing plate and the two-way cone h...

Embodiment 2

[0030] In order to transmit the force applied at the bolt head to the first positioning cylinder 5 evenly, this embodiment makes the following further limitations on the basis of embodiment 1: this embodiment also includes a spring pad 2, wherein the spring pad 2 wears It is set on the screw rod of the set bolt 1 and is set between the bolt head of the set bolt 1 and the rigid washer 3 .

Embodiment 3

[0032] In order to reduce the impact of the gap between the first positioning cylinder 5 and the screw rod of the positioning bolt 1 on the structural stability of the application of this embodiment, this embodiment makes the following further limitations on the basis of Embodiment 1 or Embodiment 2: This embodiment also includes a spring ring sleeve 4, wherein the spring ring sleeve 4 is formed by laminating a plurality of transverse springs, and all the transverse springs constituting the spring ring sleeve 4 are passed through the screw rod of the positioning bolt 1, and the spring ring sleeve 4 is arranged on The inside of the first positioning cylinder 5 and one side thereof is in contact with the rigid washer 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com