Novel medical garbage pyrolysis incinerator

A medical waste and incinerator technology, applied in the direction of incinerator, combustion method, combustion type, etc., can solve the problems of large smoke exhaust loss, smoke exhaust loss, and large consumption of auxiliary fuel in the secondary combustion chamber, so as to eliminate heat loss and reduce Effect of heat dissipation loss and accelerated drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

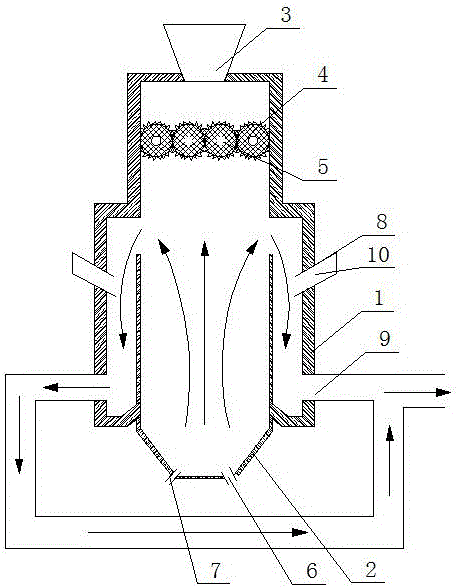

[0015] Such as figure 1 As shown, the present invention comprises an outer furnace body 1 and an inner furnace body 2 with an upper end opening, the outer furnace body 1 is set on the inner furnace body 2, and the lower end of the outer furnace body 1 is sealed and connected to the bottom of the inner furnace body 2, and the inner furnace body 2 as a pyrolysis chamber, and leave a gap with the outer furnace body 1 as a second combustion chamber, and the pyrolysis chamber and the second combustion chamber communicate with each other.

[0016] The upper end of the outer furnace body 1 is provided with a medical waste feed port 3, and a crushing device 4 is arranged in the medical waste feed port 3, and the crushing device 4 is arranged above the inner furnace body 2, and the crushing device 4 includes sequentially from left to right Two pairs of toothed roller sets are arranged, each pair of toothed roller sets includes two oppositely rotating toothed rollers 5, and the outer fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com