Assembly used for mounting radial sealing pad of air preheater

A radial sealing and air preheater technology, applied in heat exchanger sealing device, combustion method, indirect carbon dioxide emission reduction, etc., can solve the problem of increasing air leakage rate, affecting boiler operation efficiency, and increasing secondary air side smoke Air leakage and other issues on the air side to achieve the effect of optimizing the sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

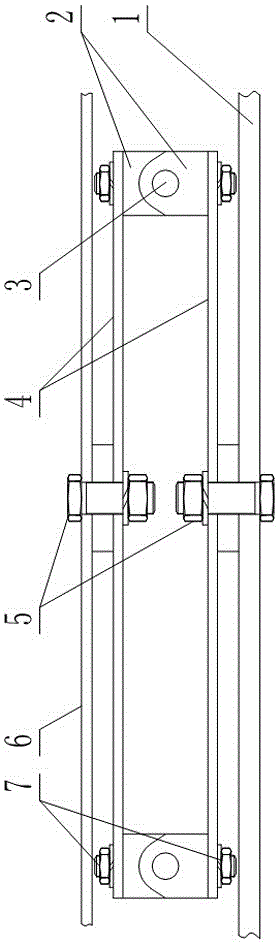

[0026] like figure 1 As shown, an assembly for installing the radial sealing plate of an air preheater includes a bimetal 4 and two rotating shafts 3 parallel to each other. The bimetal 4 is two pieces, and the two bimetal 4 The two ends of each are fixed with connection blocks 2, and the connection blocks 2 at both ends of one bimetal sheet 4 are hingedly connected to the corresponding connection block 2 on the other bimetal sheet 4 through different rotating shafts 3, and the connected two bimetal sheets The sheets 4 are in a layered relationship with each other;

[0027] When the two bimetallic strips 4 are heated, the deformation directions are opposite, and when the temperature of any bimetallic strip 4 rises, the middle part of the bimetallic strip 4 protrudes toward the side away from the other bimetallic strip 4;

[0028] When the two bimetallic strips 4 are heated and deformed, the end of at least one bimetallic strip 4 can rotate around the corresponding rotating sh...

Embodiment 2

[0032] The present embodiment is further limited on the basis of embodiment 1, as figure 1 As shown, in order to facilitate the application of this component to the air preheater, the middle parts of the two bimetallic sheets 4 are provided with the first connecting bolts 5, and one of the bimetallic sheets 4 is connected to the support through the first connecting bolts 5 on it. Plate 1, another piece of bimetal 4 is connected with pallet 6 through the first connecting bolt 5 on it. The above support plate 1 is used for the installation of this component on the air preheater, and the above tray 6 is used for installing the sealing sheet.

[0033] Since the ambient temperature of the assembly changes greatly, in order to improve the anti-loosening performance between the components in the assembly, each first connecting bolt 5 is provided with a spring washer.

[0034] When the ambient temperature of the assembly changes, the distance between the connecting block 2 on each bi...

Embodiment 3

[0038] This embodiment is further limited on the basis of any one of the technical solutions provided by any one of the above embodiments, and the two bimetallic sheets are wrapped with a heat-resistant layer. The heat-resistant layer is used to delay the temperature change of the bimetal: because the deformation of the rotor is relatively slow, by setting the heat-resistant layer, the thermal resistance of the heat-resistant layer can prolong the time of the temperature change process of the bimetal to avoid the deformation of the rotor. When it is small, such as during a period of time when the air preheater is just started, the large deformation of the bimetal will cause excessive force between the sealing plate and the sector plate, thus causing damage to the sealing plate or the bimetal.

[0039] In this embodiment, the above heat-resisting layer adopts heat-retaining glass fiber or nano heat-insulating material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com