Support bearing for groove type heat collector and photothermal power generation system including support bearing

A technology for trough collectors and support bearings, which is applied to the fixed base/support of solar collectors, photovoltaic power generation, solar thermal power generation, etc., and can solve the problems of accelerating column foundation settlement speed, circuit support damage, difficult precision requirements, etc. problems, to achieve the effect of improving the installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

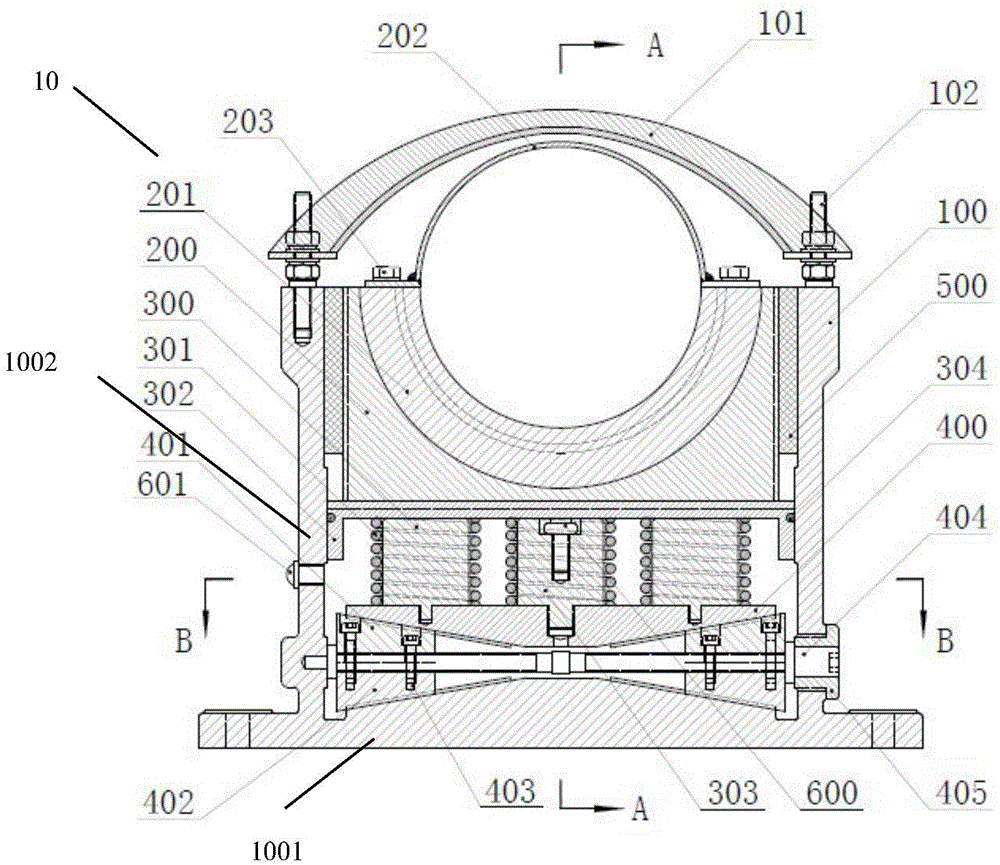

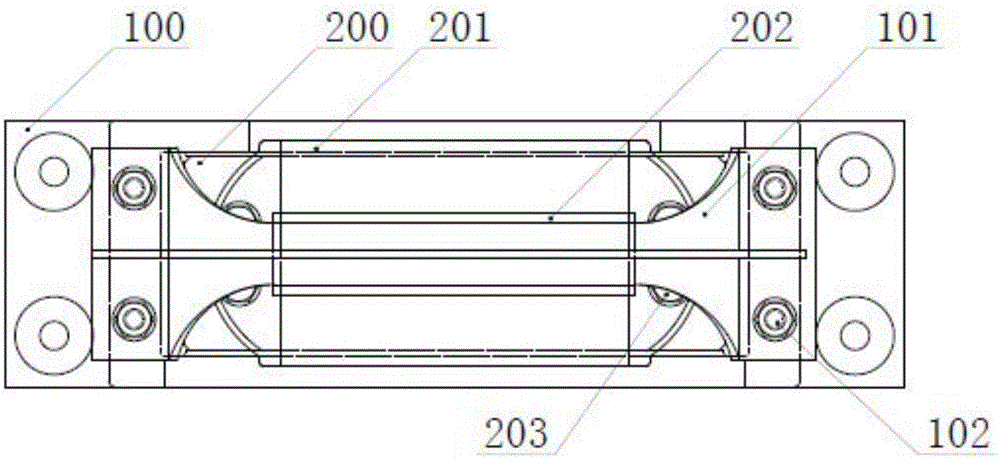

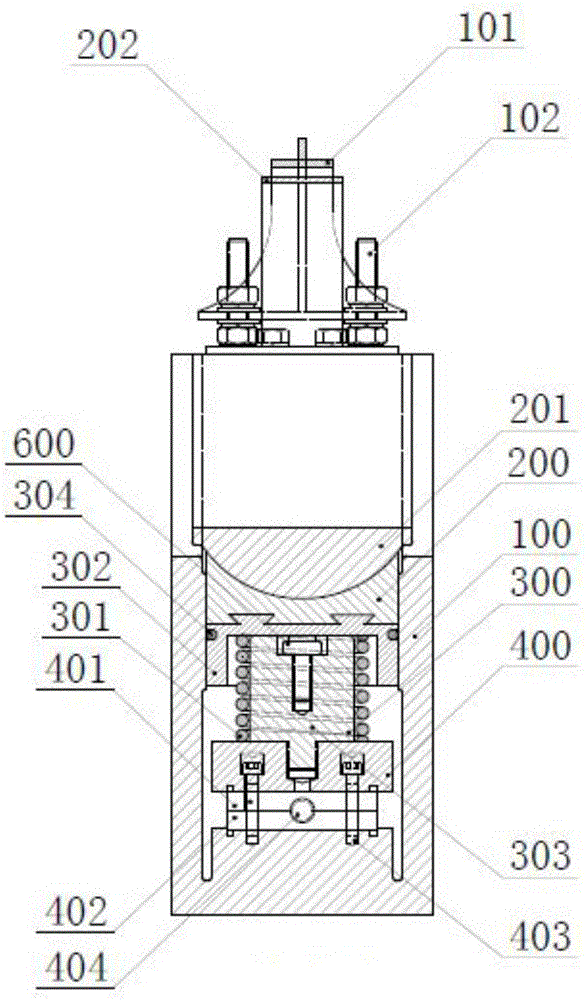

[0028] The support bearing of the present invention will be further described in detail, exemplary and non-limiting in conjunction with the accompanying drawings.

[0029] Such as Figure 1-4 As shown, according to an embodiment of the present invention, the support bearing 10 may include a bearing housing 100, a safety cover 101, a safety cover fixing bolt 102, a bearing seat 200, a semicircular ball bearing 201, a bearing cover 202, and a bearing cover fixing bolt 203, lifting plate 302, a plurality of spring columns 300,303, springs 301, sealing rings 304, height adjustment plate 400, double wedge adjustment plate including wedge adjustment block upper plate 401 and wedge adjustment block lower plate 402, wedge shape adjustment block are set on the column Adjusting block fixing bolt 403, height adjusting screw rod 404, height adjusting screw rod lock nut 405, pressure sensor 600 and waterproof joint 601 installed on the interface. The structure and function of each compone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com