Method for utilizing hollow electric compensation electrode to monitor vertical calculating capacitor

A technology for calculating capacitance and electrical compensation, applied in capacitance measurement, measurement of resistance/reactance/impedance, measurement devices, etc., can solve problems such as affecting the measurement accuracy of the system, non-parallel metal main electrodes, and increased non-cylindricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082] Below in conjunction with accompanying drawing, the present invention is described in further detail:

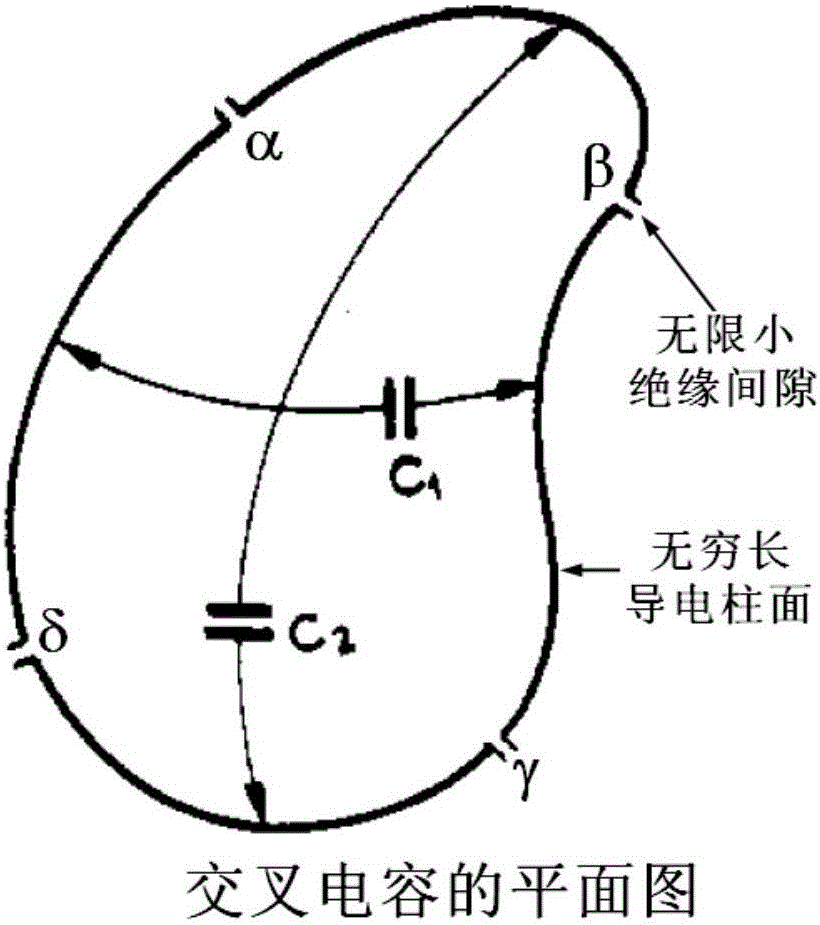

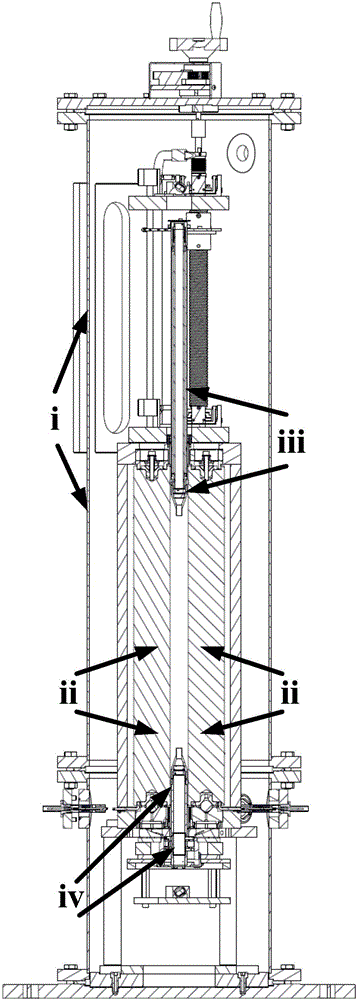

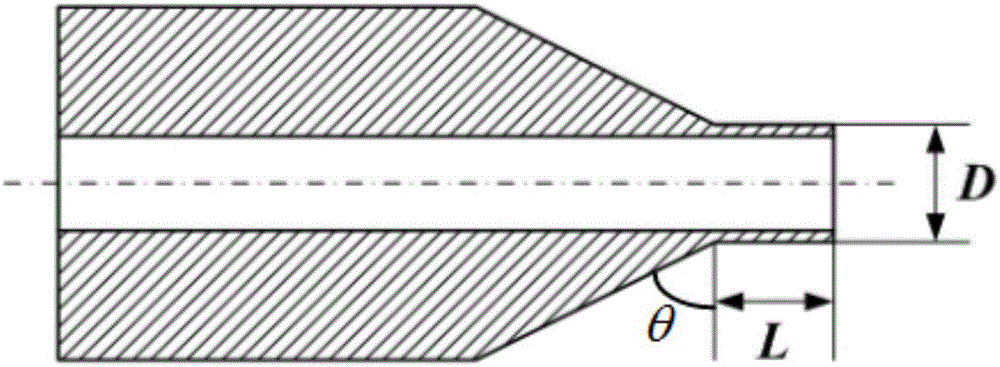

[0083] The present invention first proposes a measurement sensitivity k of a hollow electric compensation electrode to a single metal main electrode position change ONE With the measurement sensitivity to the change of the electrode spacing of all four metal main electrodes k ALL At the same time, a method for monitoring and measuring the actual vertical calculation capacitance of the hollow electrical compensation electrode is proposed, that is, when the movable shielding electrodes in the vertical calculation capacitance device are respectively located at the lowest position and the highest position, the commercial capacitance is used The electric bridge measures the capacitance difference between the ring-shaped auxiliary electrode in the hollow electrical compensation electrode structure at two positions and each metal main electrode in the vertical calculation ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com