System and method for predicting drum water level of circulating fluidized bed domestic garbage incineration boiler

A domestic waste incineration and circulating fluidized bed technology, applied in special data processing applications, complex mathematical operations, instruments, etc., can solve the problems of inhomogeneity, dependence on working conditions, and limited heat absorption of water-cooled walls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

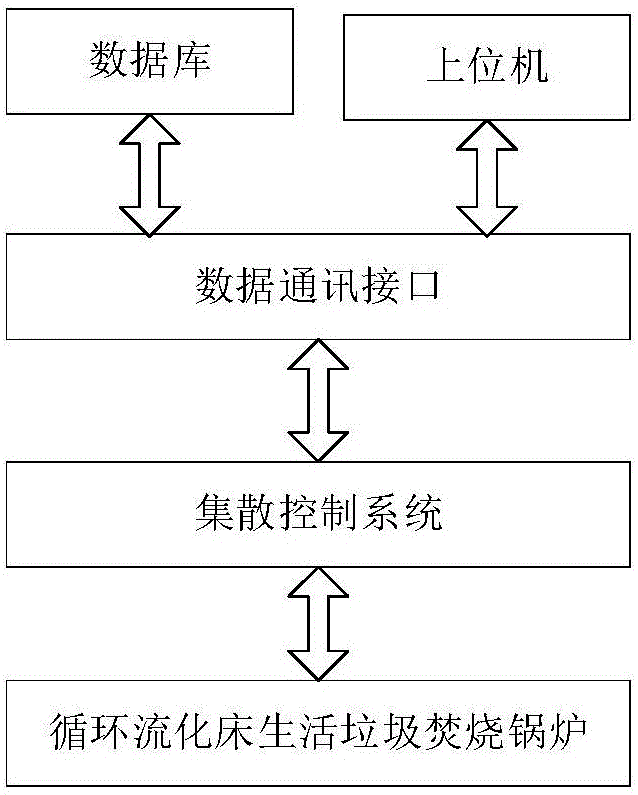

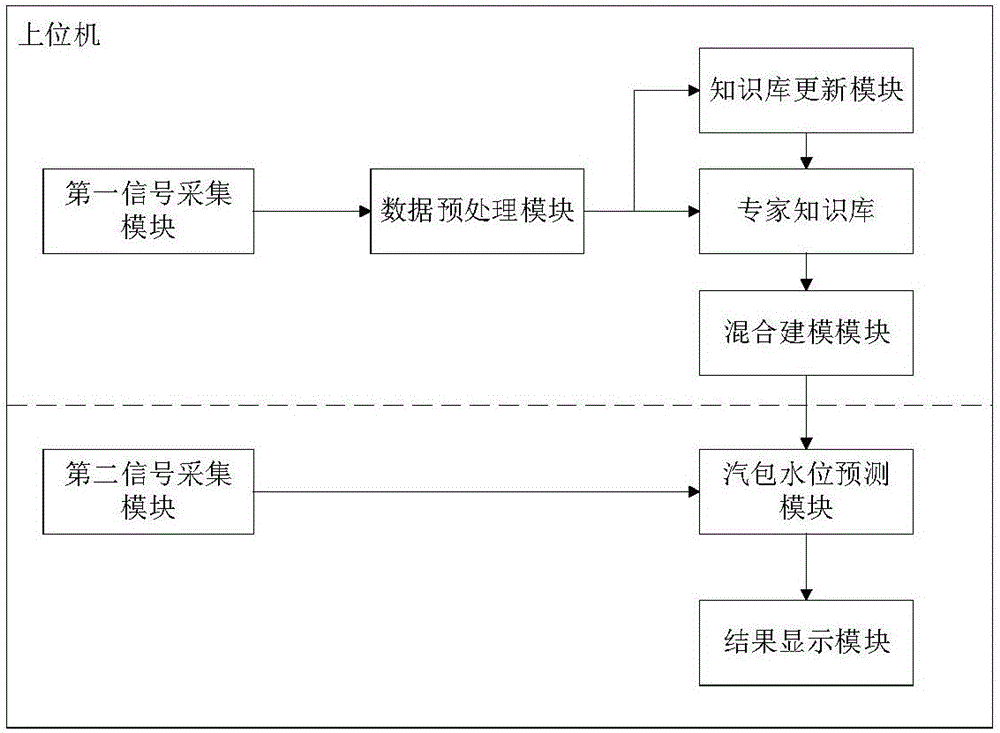

[0180] Such as Figure 1-5 As shown, the present invention provides a system for predicting the drum water level of a circulating fluidized bed domestic waste incineration boiler. The system is connected with the distributed control system of the circulating fluidized bed boiler, including a data communication interface and a host computer, and the host computer includes:

[0181] The first signal acquisition module. Among the model input variables, the operating parameters of the boiler need to be collected from the DCS system. Use the first signal acquisition model to collect the operating condition parameters and operating variables of the CFB domestic waste incineration boiler during normal operation, and form the training sample matrix X(m×n) of the input variables of the ANIFS drum water level compensation model, where m represents the sample The number, n represents the number of variables, among which the parameters of feed water flow, feed water temperature, main st...

Embodiment 2

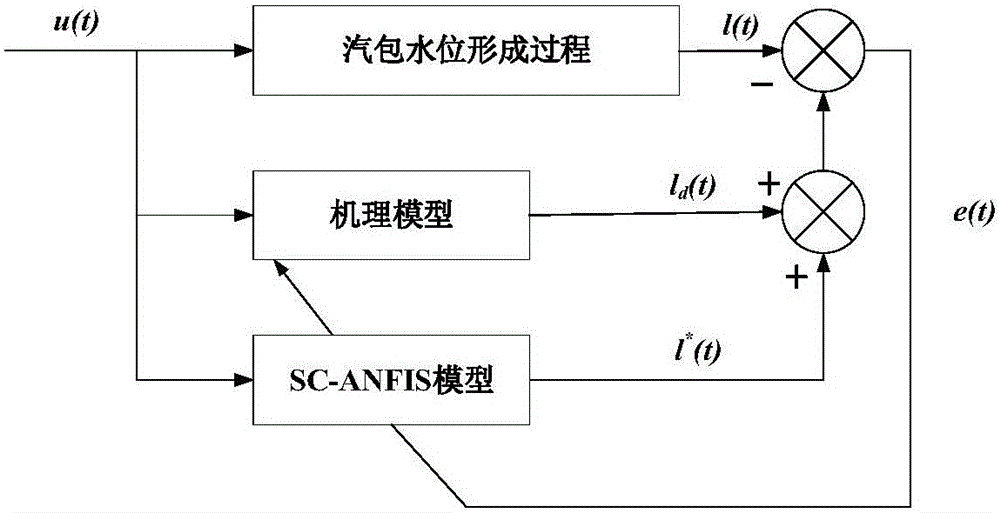

[0293] refer to figure 1 , figure 2 , image 3 , Figure 4 , a method for predicting the drum water level of a circulating fluidized bed domestic waste incineration boiler provided by the invention, the method comprises the following steps:

[0294] 1) Select the input variables of the mixed model and collect training samples. The water level of the boiler drum is mainly determined by the state of the working fluid and the material energy balance in the steam drum. There are many factors that affect the change of the water level of the steam drum, mainly including the design parameters of the boiler, the physical parameters of the working fluid and the operating parameters. The design parameters mainly include the equivalent pipe diameter of the water wall, the effective heat absorption length of the water wall, the volume of the water wall, the flow rate of circulating water, the volume of the steam drum, the average cross-sectional area of the steam drum, the volume of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com