Portable board assembly device

An assembly device and a portable technology, which is applied in the manufacture of wire harnesses, electrical components, circuits, etc., can solve the problems of reduced work efficiency, destructive drawings, and reduced assembly accuracy, so as to improve work efficiency, facilitate reference, and improve assembly accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

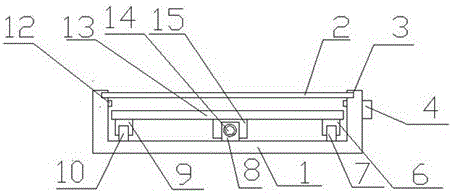

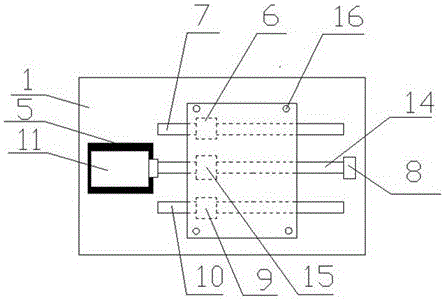

[0017] figure 1 with figure 2 A specific embodiment of the present invention is shown: a portable chopping board assembly device, including an installation groove 1 and a glass plate 2, one side of the installation groove 1 is open, and the glass plate 2 is arranged on the installation groove 1, and It is detachably connected with the installation groove 1, and the installation groove 1 is provided with a driving device and a drawing positioning magnetic plate 13. The driving device includes a motor 11, a lead screw 14, a lead screw nut 15, a first slide rail 10, a second Slide rail 7, first slide block 9 and second slide block 6, the outer wall of described mounting groove 1 is provided with power control device 4, and described motor 11 is connected with power control device 4 by wire, and described first slide rail 10 and the second slide rail 7 are respectively arranged on both sides of the bottom of the mounting groove 1, the mounting groove 1 is provided with a support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com