A suspended surface mount fuse

A surface mount and fuse technology, applied in the field of electric power, can solve the problems of limited fuse length, space occupation, small fuse length, etc., and achieve the effects of preventing explosive damage, high anti-lightning characteristics, and explosion-proof volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

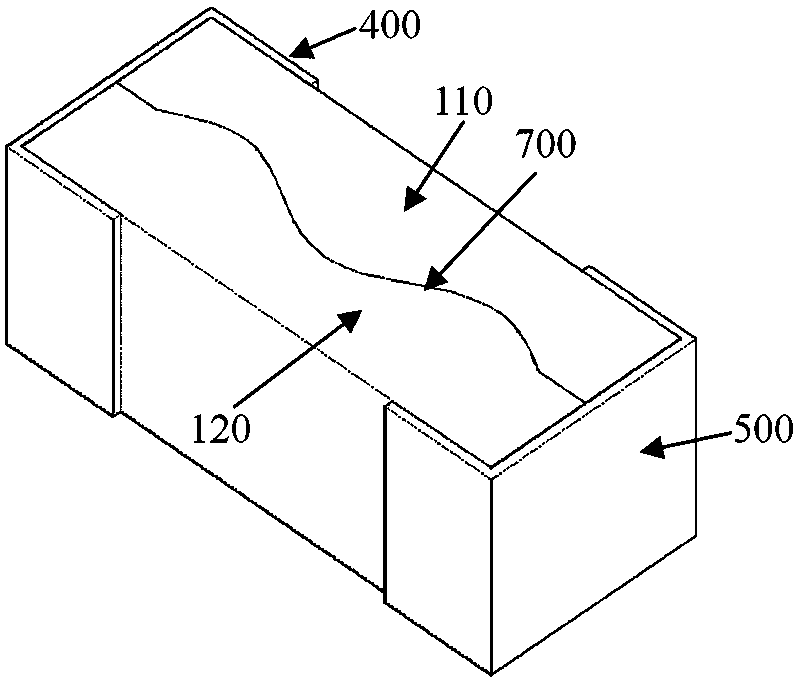

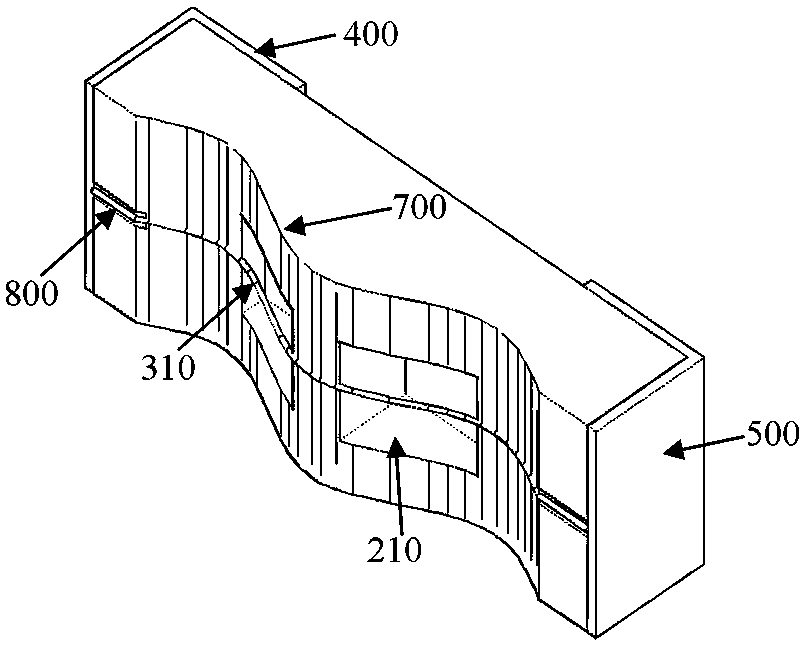

[0036] Such as figure 1 and figure 2 The shown suspended surface mount fuse includes an upper substrate 110 and a lower substrate 120 , and a fuse 310 is located between the upper substrate 110 and the lower substrate 120 . The upper substrate 110 and the lower substrate 120 assembled together are provided with terminal electrodes at the left and right ends, and the terminal electrodes include surface terminal electrodes 400 covering both ends of the upper surface of the upper substrate and both ends of the lower surface of the lower substrate and covering the upper and lower electrodes. The end electrodes 500 on the left and right end surfaces of the substrate, the surface end electrodes 400 and the end electrode 500 are structurally connected to form a "]"-shaped structure covering the ends of the upper and lower substrates, the end electrodes 500 and the fuse 310 It is electrically connected to the surface terminal electrode 400 .

[0037] The upper substrate 110 and the...

no. 2 example

[0050] Such as Figure 8 As shown, on the basis of the first embodiment, both the upper substrate 110 and the lower substrate 120 are an assembly structure composed of an inner wall coating with a non-planar wave structure 700 and an outer cover plate, and the upper substrate 110 is composed of an upper The cover plate and the upper inner wall coating 910 are formed, the lower substrate 120 is composed of the lower cover plate and the lower inner wall coating 920, the upper surface of the upper inner wall coating 910 is closely attached to the lower surface of the upper cover plate, and the lower inner wall coating The lower surface of the layer 920 is close to the upper surface of the lower cover plate, the shape of the upper inner wall sticker 910 and the lower inner wall sticker 920 are in conformity with the non-planar wave structure 700, and the fuse 310 passes between the upper inner wall sticker 910 and the lower inner wall sticker 920. Pass. Different from the first e...

no. 3 example

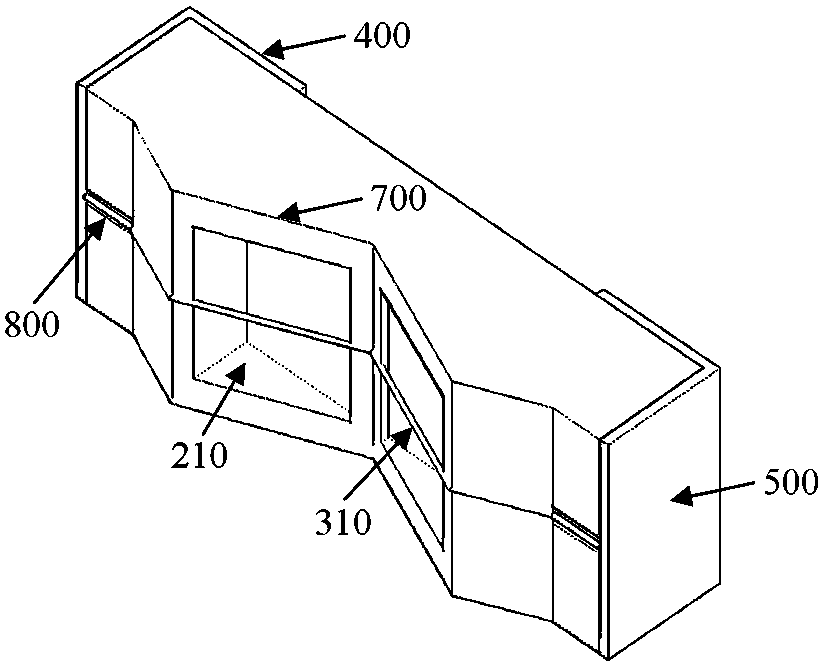

[0061] Such as Figure 9 As shown, on the basis of the first embodiment, the width of the non-planar wave structure 700 is set to be smaller than the width of the abutting surface of the upper substrate 110 and the lower substrate 120 .

[0062] This embodiment can also be improved on the basis of the second embodiment, and a rectangular groove is provided on the inner surface of the upper cover plate and the lower cover plate, and the width of the upper inner wall sticker 910 and the lower inner wall sticker 920 is smaller than the rectangular groove Width, put the upper inner wall sticker 910 and the lower inner wall sticker 920 into the rectangular grooves of the upper cover and the lower cover respectively, that is, stick together to form the upper substrate 110 and the lower substrate 120 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com