Separation equipment for current collector and active material of waste pole pieces

A technology of active materials and separation equipment, applied in the direction of waste collector recycling, recycling technology, electrochemical generators, etc., can solve problems such as low efficiency and incomplete separation, improve durability, reduce separation costs, and avoid margins The effect of streaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

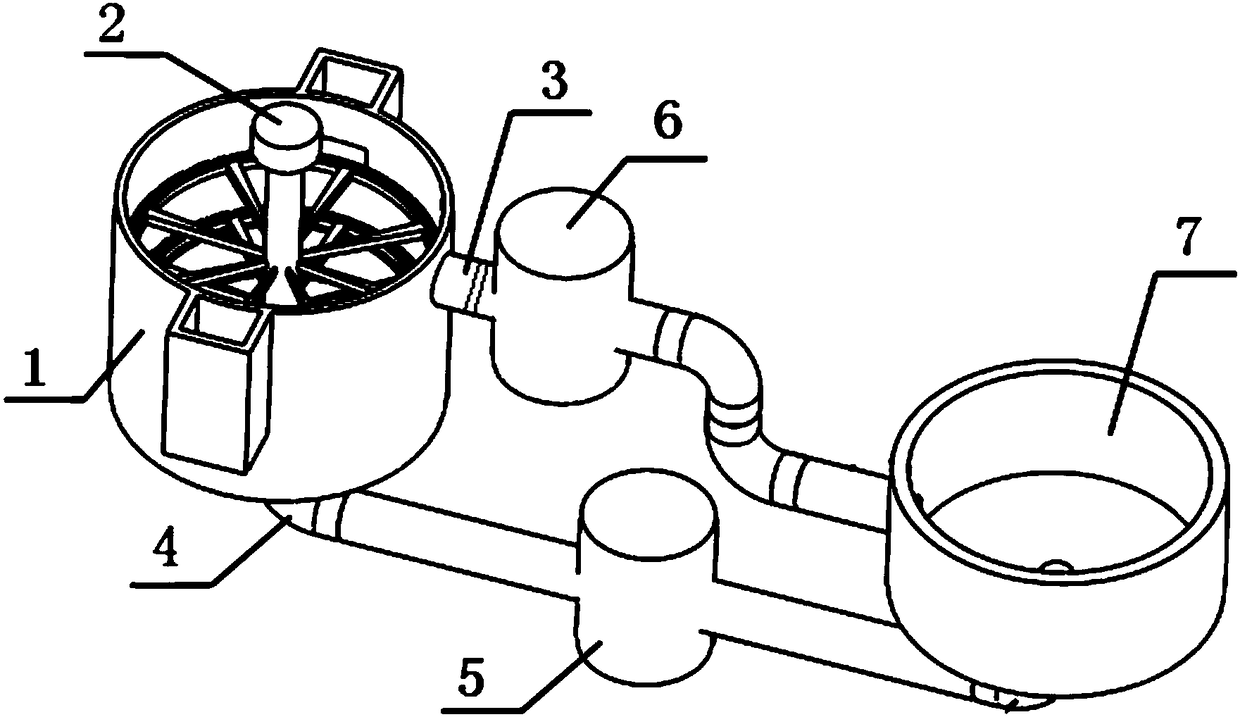

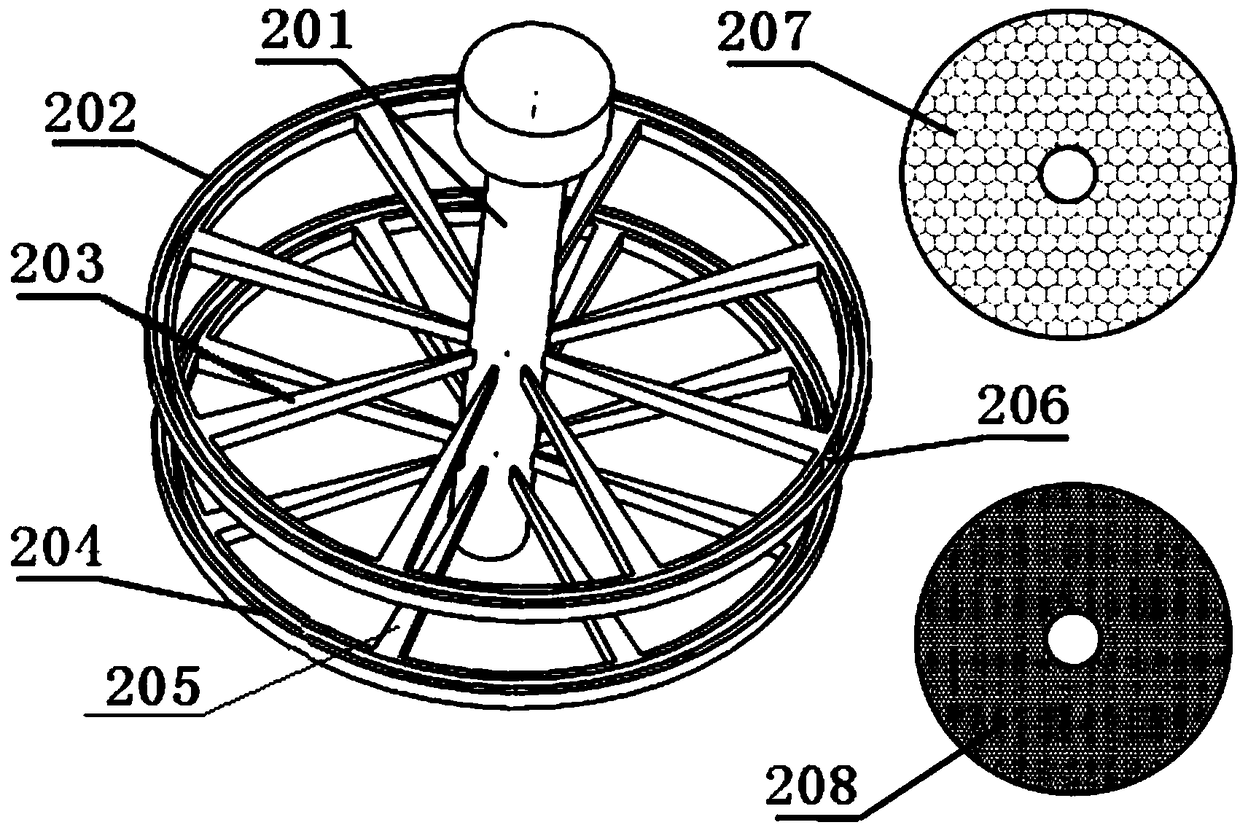

[0028] Such as figure 1 As shown, a separation device for current collectors and active materials of waste pole pieces includes a separation agitator and a liquid storage tank 7, and the separation agitator includes a separation bucket 1 and an agitator 2 disposed therein, and the separation bucket The interior of 1 is horizontally provided with a coarse filter 207 and a fine filter 208 from top to bottom, a liquid injection port 3 is provided on the side wall of the separation barrel 1 above the coarse filter 207, and an outlet is provided at the bottom of the separation barrel 1. Liquid port 4; the liquid injection port 3 is connected to the outlet of the liquid storage tank 7 through the high pressure pump 6, and the liquid outlet 4 is connected to the return port of the liquid storage tank 7 through the normal pressure pump 5.

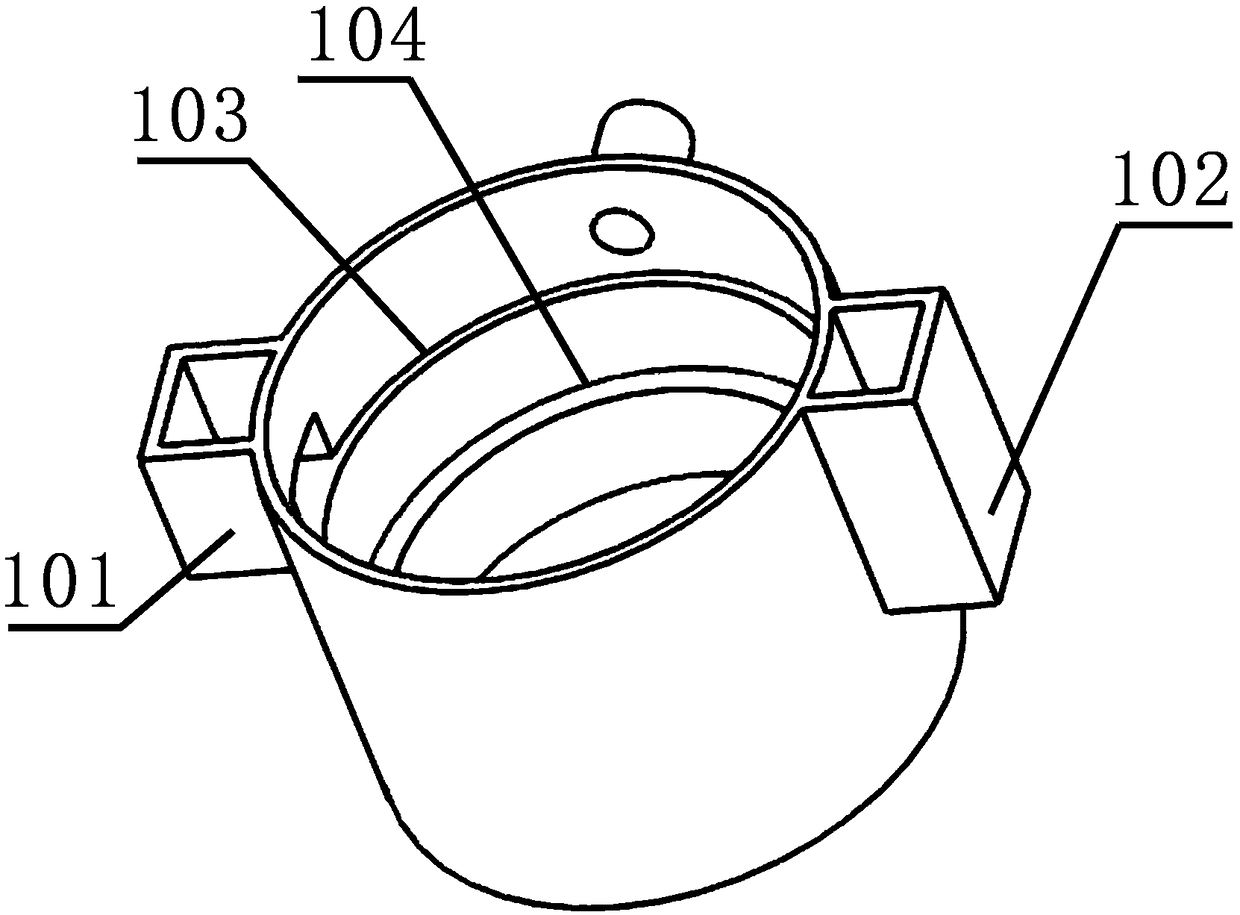

[0029] Such as figure 2 As shown, the outer wall of the separation bucket 1 is provided with a collector collection tank 101 and a powder collec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com