Exposure device and method for inspecting the same

A technology of exposure device and light source device, which is applied in the direction of lighting device, optics, light source, etc., and can solve the problem that it is difficult to identify whether the lamp is genuine or not

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

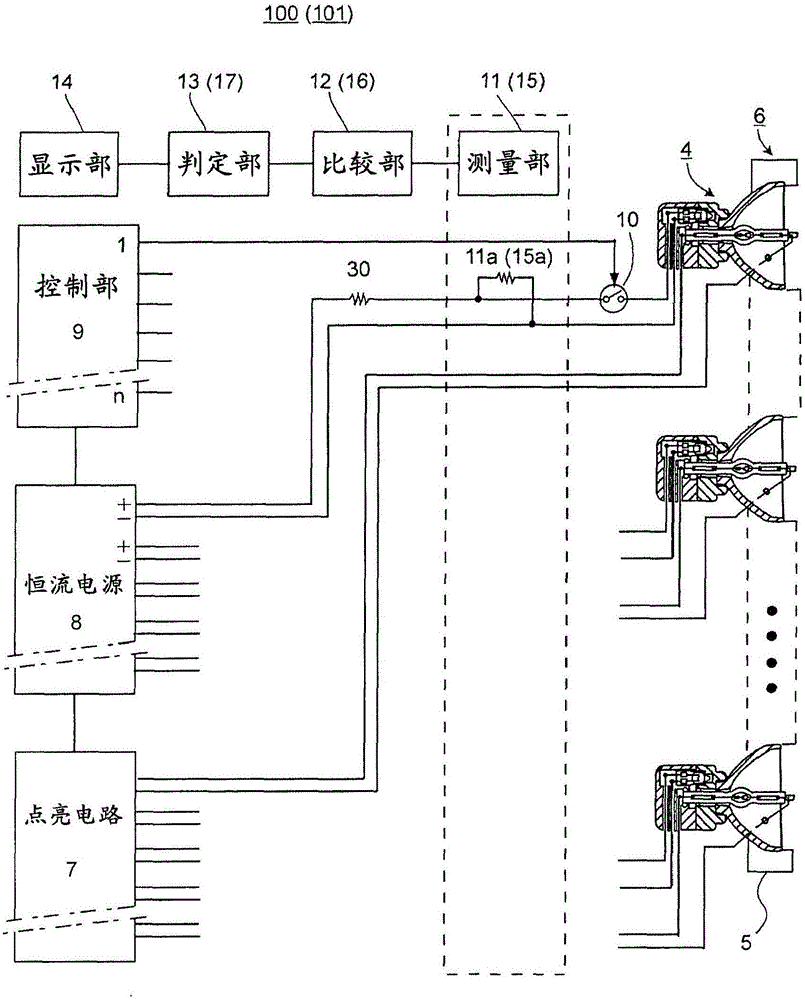

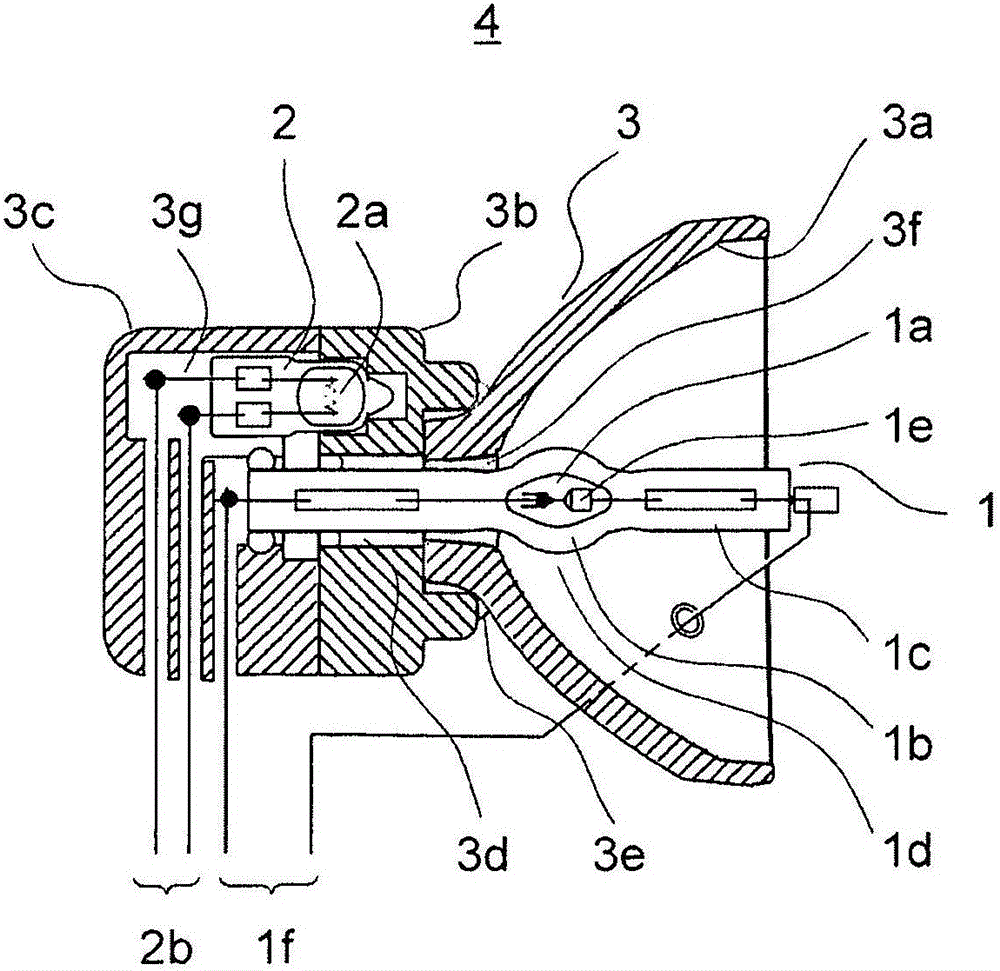

[0031] exist figure 1 In this case, when the power switch of the exposure apparatus 100 is turned on, the lighting circuit 7 supplies power to all the discharge lamps 1 . Usually, it takes several minutes for the discharge lamp 1 to start up completely. Immediately after the power switch of the exposure apparatus 100 is turned on, the control unit 9 turns on the first switch 10 connected to the first incandescent lamp 2 in the light source device 4 to supply a constant current from the constant current power supply 8 . After a predetermined time (for example, after 10 seconds) from the conduction of the first switch 10, the voltage across the first incandescent lamp 2 is measured by the measuring part 11, and the result is sent to the comparing part 12, and the comparing part 12 compares the The result and the voltage distribution ranges of a plurality of incandescent lamps for authentic product detection registered in the comparison unit 12 in advance will be sent to the det...

Embodiment 2

[0037] exist figure 1 Among them, the elements different from those in Example 1 are the measurement unit 15 (the internal resistance is the resistance 15a), the comparison unit 16, and the determination unit 17, and the other elements are the same. Description of the same elements as those in Embodiment 1 is omitted. Immediately after the exposure device 101 turns on the power switch, the first switch 10 connected to the first incandescent lamp 2 in the light source device 4 is turned on to supply a constant current from the constant current power source 8 . Immediately thereafter, the first measurement of the voltage across the first incandescent lamp 2 is performed by the measurement unit 15 , and the result is sent to the comparison unit 16 . Then, after a predetermined time (for example, after 10 seconds) from the first measurement, the second measurement of the voltage across the first incandescent lamp 2 is carried out by the measurement part 15, and the result is sent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com