Supersonic measuring sensor for water meter, heat meter and flowmeter and using method of sensor

A measurement sensor and ultrasonic sensor technology, applied in the fields of sensing and acoustics, can solve the problems of long installation length, inconvenient operation, moving parts, etc., and achieve the effect of small installation size, favorable for instrument measurement, and reduced volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

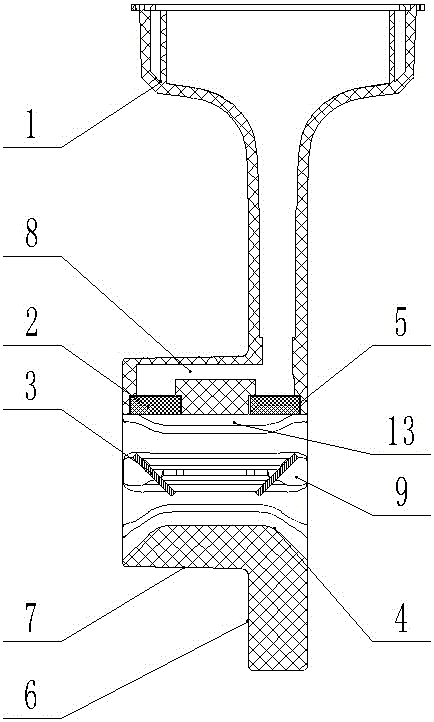

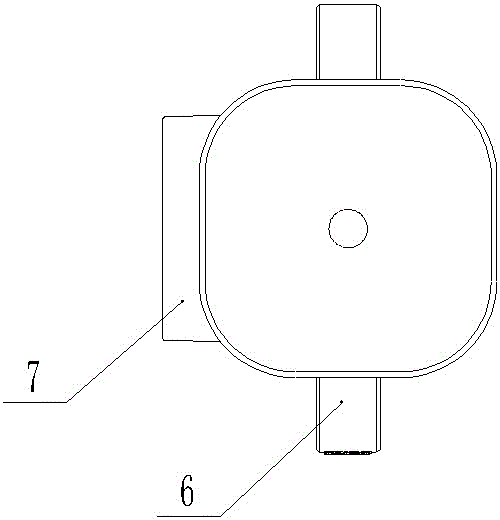

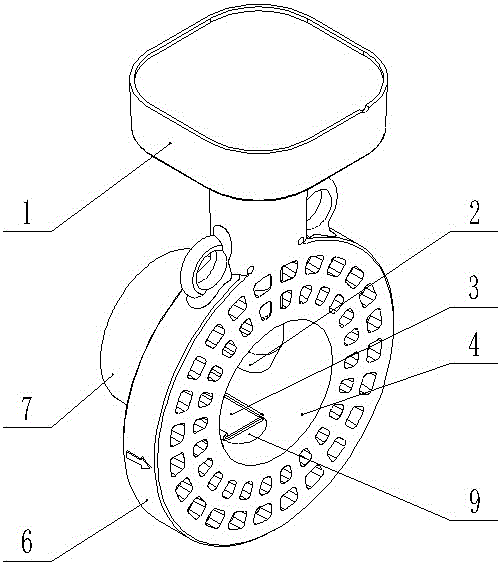

[0068] Embodiment one, with reference to the attached figure 1 , 2 , 3, 4, 5. The measuring pipe section is composed of the wafer body 6 and the guide beam tube 7. The guide beam tube is arranged on one side of the wafer body instead of being symmetrically or asymmetrically arranged on both sides of the wafer body. At the same time, sensors are arranged on the guide beam tube The installation hole 5 , the ultrasonic sensor is arranged in the sensor installation hole; a reflector is arranged in the guide beam tube, and the reflector 3 matches the ultrasonic sensor 2 .

[0069] In this embodiment, the clip body 6 and the guide beam tube 7 are an integral structure, and two reflectors are arranged in the guide beam tube 7, and the reflector is composed of a reflective surface and a support frame, and the reflective surface is arranged on the support frame. The support frame is clamped on the positioning installation slot 9 of the inner pipe section wall of the guide beam tube, ...

Embodiment 2

[0073] Embodiment two, with reference to attached Image 6 , 7 , the measuring pipe section is composed of the wafer body 6 and the guide beam tube 7, the guide beam tube is arranged on both sides of the wafer body, asymmetrically arranged, the length of the guide beam tube exposed on both sides of the wafer body 6 is not equal, and the exposed The long side mainly plays the role of diversion and water diversion, and the exposed shorter side mainly plays the role of fixing the limit gasket; at the same time, a sensor installation hole is arranged on the guide beam tube, and the ultrasonic sensor is arranged in the sensor installation hole 5; the guide A reflector 3 is arranged inside the beam tube, and the reflector matches the ultrasonic sensor.

[0074] Exposing the shorter side is a raised positioning platform 14, which mainly plays the role of fixing the spacer gasket, and its height does not exceed the height of the gasket.

[0075] In this embodiment, the clip body 6 a...

Embodiment 3

[0076] Embodiment three, with reference to the attached Figure 8 , 9 , the measuring pipe section is composed of the wafer body 6 and the guide beam tube 7, the guide beam tube is arranged on one side of the wafer body instead of being symmetrically or asymmetrically arranged on both sides of the wafer body, and at the same time, the guide beam tube is provided with The sensor installation hole, the ultrasonic sensor is arranged in the sensor installation hole 5 .

[0077] A reflector 3 is arranged on the tube wall inside the guiding beam tube, the reflector matches the ultrasonic sensor, and the measurement is completed after reflection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com