Design method for sliding mode disturbance observer used for servo system control

A disturbance observer and servo system technology, applied in control systems, DC motor speed/torque control, electrical components, etc., can solve problems such as large gain chattering, meet the requirements of reducing modeling accuracy and improve robustness and anti-interference ability, reducing the effect of jitter problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A design method for a sliding mode disturbance observer for servo system control, the steps are as follows:

[0042] 1. Design of sliding mode controller

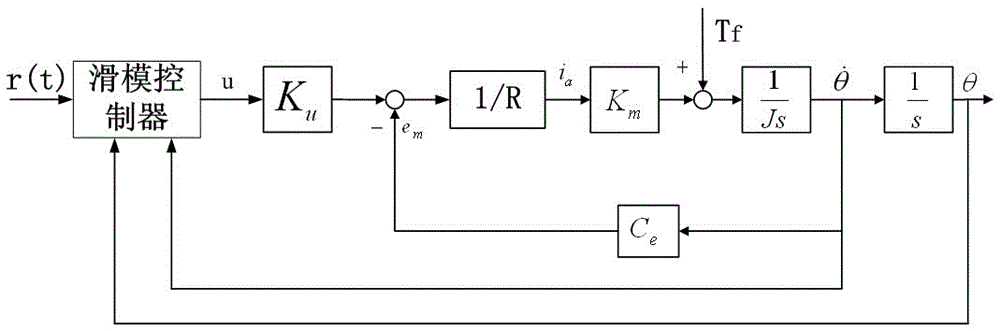

[0043] like figure 1 It means that a sliding mode controller is used to control a servo system affected by friction. First, the state equation of the servo system is established as shown in equation (1):

[0044]

[0045] where r(t) is the command signal, u is the control input, C e is the back EMF coefficient of the motor, K u is the amplification factor of the PWM drive, R is the armature resistance, K m is the moment coefficient, J is the moment of inertia, T f Indicates the frictional disturbance torque. state variable x 1 represents the angle of rotation, x 2 Indicates rotational speed.

[0046] The tracking errors of angular position and angular velocity are respectively

[0047] e=r-x 1 (2)

[0048]

[0049] Design switching function

[0050]

[0051] Exponential Reach Law

[0052]

...

Embodiment 2

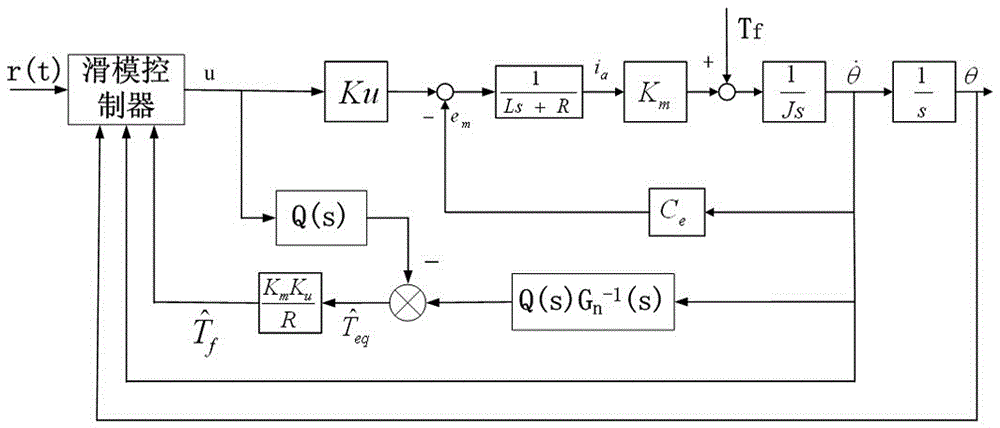

[0070] Known parameters of the controlled motor servo system: R=14.7Ω, K m =1.134N m / A, C e =0.119V / (r / min), J=1.79*10 -6 kg*m 2 , K u = 12.

[0071] The transfer function of the motor is

[0072]

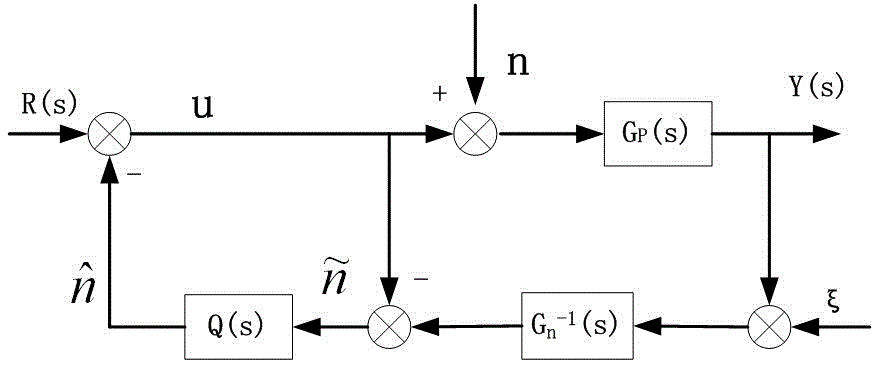

[0073] Select the parameter τ=0.001ms of the low-pass filter Q(s), then

[0074]

[0075] Then according to Q(s) and G p (s), construct a disturbance observer to get the estimated value of friction torque Select c=30, k=1, ε=1 as the control parameters to design the control rate u.

[0076]

[0077] Through computer simulink simulation, compare the quality of PID control and sliding mode disturbance observer control.

[0078] First, the double closed-loop PID control of the speed loop and the position loop is used. The rule for selecting PID parameters is: first, regardless of the nonlinear friction part of the motor, the PID coefficients of the speed loop and the position loop are determined in turn by the critical proportionality method, and then the coefficient...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com