Large-scale rice-wheat-production biogas-liquid spraying device based on pipe delivering

A technology of pipeline transportation and biogas slurry, which is applied in fertilization devices, liquid fertilizer distribution, and pressure spreading methods of liquid fertilizers, etc., can solve the problems that affect the normal movement of sprayers, the normal walking of operators, the inability of sprayers to be combined, and the inconvenience of use. and other problems, to achieve the effect of good practical effect, flexible adjustment of pipeline length, and avoidance of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

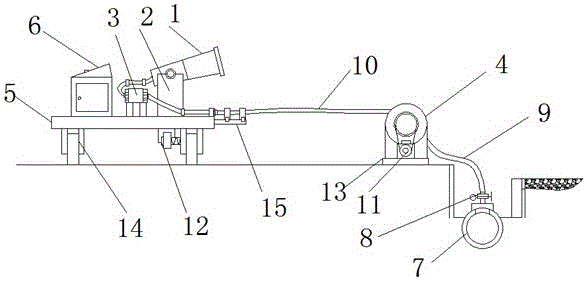

[0018] Embodiment 1: as figure 1 , 2 A biogas slurry spraying device for large-scale rice and wheat production based on pipeline transportation shown in and 3, the biogas slurry spraying device includes a sprayer nozzle 1, a nozzle bracket 2, a hydraulic pump 3, and a fixed coil frame 4 , mobile platform 5 and control system 6, described sprayer nozzle 1 is fixedly installed on the mobile platform 5 by nozzle bracket 2, and the bottom of described sprayer nozzle 1 is connected on the hydraulic pump 3 by liquid supply pipeline, so The hydraulic pump 3 is connected to the fixed coil rack 4 through a pipeline, the fixed coil rack 4 is fixedly installed on the road surface, and the fixed coil rack 4 is provided with a liquid inlet pipe 9 and a liquid outlet pipe. Pipe 10, the liquid outlet pipe 10 is connected to the hydraulic pump 3, and the liquid inlet pipe 9 is connected to the valve 8 of the biogas slurry transportation pipeline 7 in the field.

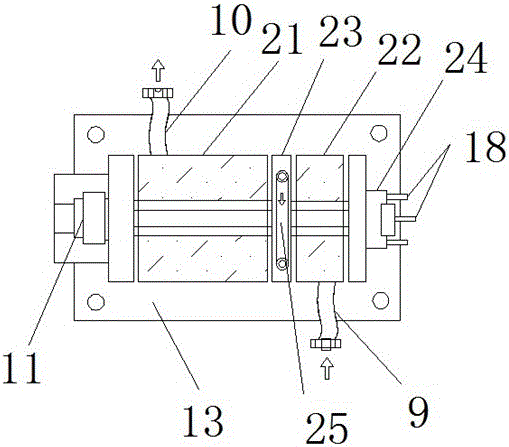

[0019] The fixed coil rack ...

Embodiment 2

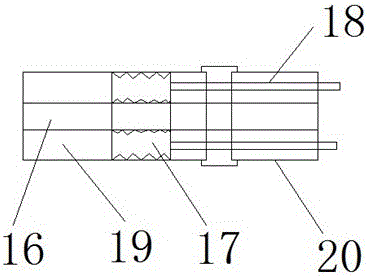

[0020] Embodiment 2: as figure 1 , 2 As shown in and 3, the transmission gear 17 of the present invention is movably installed between the connecting chamber 19 or 20 and the transmission shaft 16, and one end of the transmission gear 17 is provided with a connecting rod 18, and the transmission gear 17 is connected to the incoming shaft by the connecting rod 18. On the positioning block 24 on the side of the liquid disc 22; by adjusting the connecting rod 18 on the positioning block 24, and then adjusting the position of the transmission gear 17 in the connecting cavity 19 or 20, different circles on the fixed coil rack 4 can be flexibly selected. Disk 21 or 22, and then control the liquid outlet pipe 10 and the liquid inlet pipe 9 on the coil rack 4 respectively.

Embodiment 3

[0021] Embodiment 3: as figure 1 , 2 As shown in and 3, the transmission gear 17 of the present invention slides left and right in the horizontal direction in the connecting chamber 19 or 20 through the connecting rod 18; due to the presence of multiple valves 8 on the biogas slurry pipeline 7, they are in different positions of the biogas slurry pipeline 7 On the other hand, when the valve 8 at one position fails, it is necessary to adjust the length of the liquid inlet pipe 9 on the liquid inlet coil 22 to select it to connect with the valve 8 at a different position; and the mobile platform 5 itself is free in the field. It is mobile, so it is necessary to control the length of the liquid outlet pipe 10 through the liquid outlet coil 21, so that the normal working length between the liquid outlet pipe 10 and the mobile platform 5 is maintained, so as to avoid the messy placement of the liquid outlet pipe 10 in the field and affect the mobile platform. 5 and the normal walk...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com