Root-tuber crop harvester

A harvester and rhizome technology, which is applied in the field of rhizome crop harvesters, can solve the problems of farmers' labor intensity, resistance, and resistance to entry into the soil, and achieve the effects of easy entry into the soil, reasonable structure, and labor-saving entry into the soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

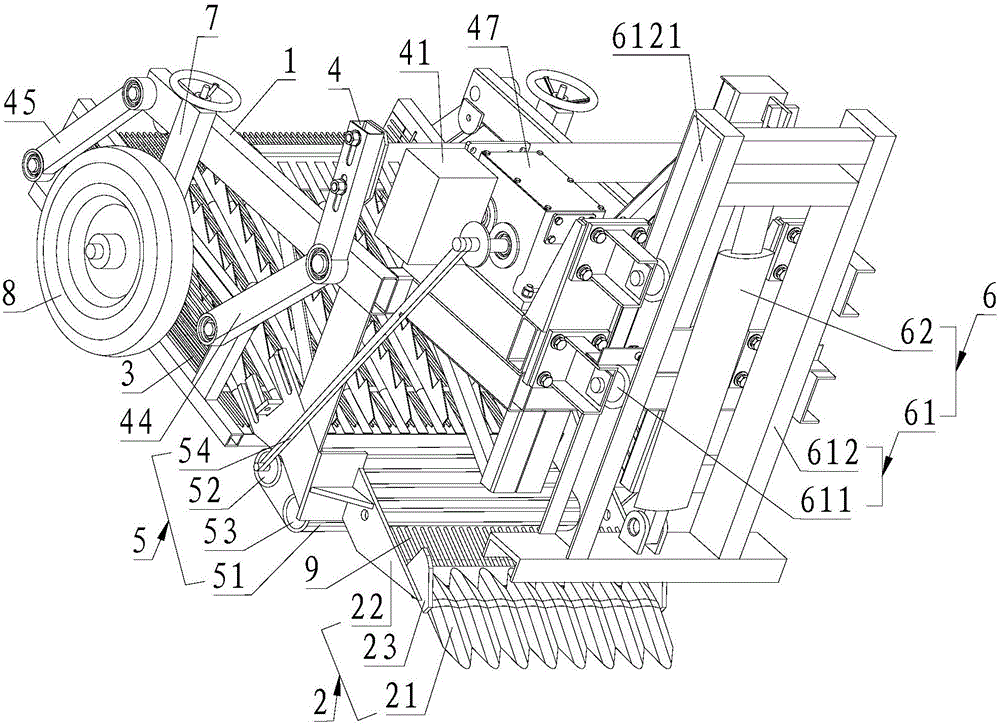

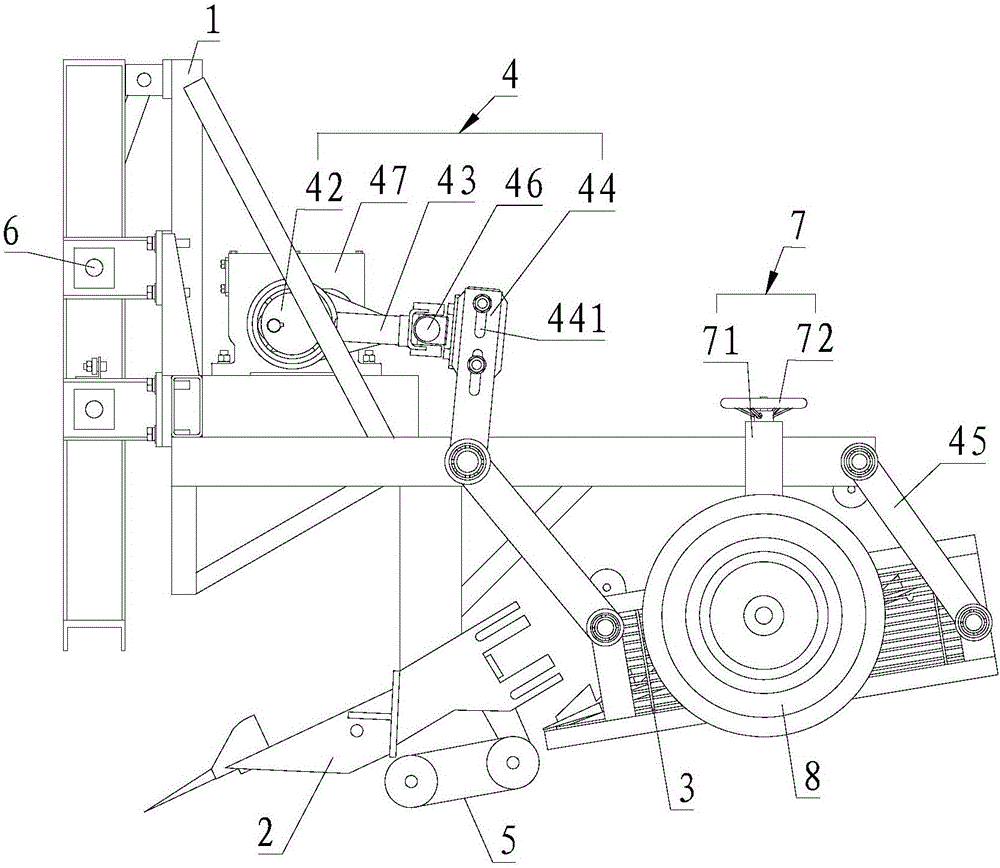

[0065] Please refer to Figure 1 to Figure 8 , Embodiment 1 of the present invention is:

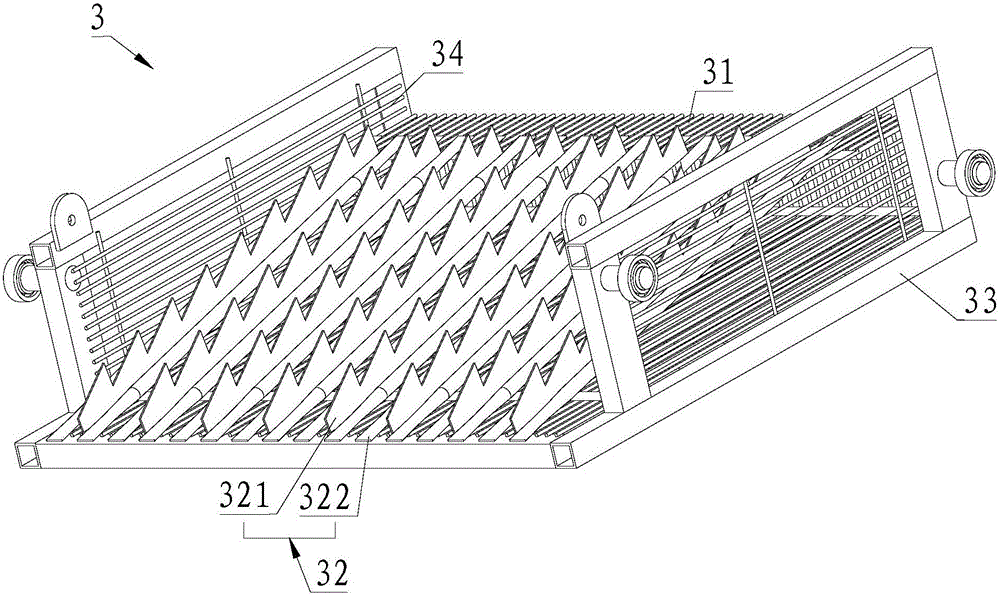

[0066] A harvester for rhizome crops, comprising a frame 1, an excavating shovel 2, a vibrating screen 3, a vibrating mechanism 4, a transmission mechanism 5, grid bars 9, a depth adjustment mechanism 6, two angle adjustment mechanisms 7 and two rear wheel 8, the front end of the excavating shovel 2 is a blade portion, and the blade portion is composed of at least two parallel and adjacent rectangular blades 21, the front ends of the rectangular blades 21 are arc-shaped, and the rectangular blades 21 The upper edge of the transverse section is arched, the upper edge of the longitudinal section of the rectangular blade 21 is arched, and the two sides of the excavating shovel 2 are provided with first baffles 22, and the first baffles 22 The projected shape of the first baffle plate 22 is Z-shaped, and the plate in the middle of the first baffle plate 22 is vertically arranged and abuts a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com