Air purifying filter element

An air purification and filter element technology, applied in the field of air purification, can solve the problems of high price, poor sterilization, poor dust filtering effect and high production cost, and achieve the effect of comprehensive filtering effect, reducing production cost and simple structure of the filter element.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

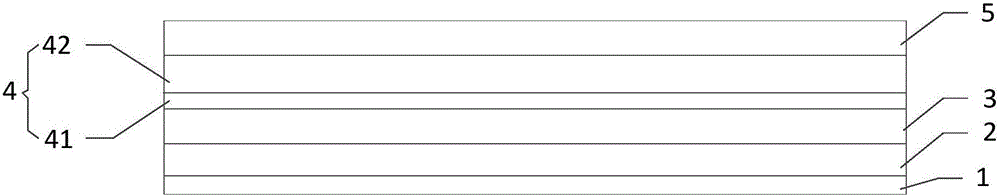

[0021] Such as figure 1 As shown, the air purification filter element in this embodiment includes a bottom skeleton layer 1, a melt-blown non-woven fabric layer 2, an electrostatic adsorption layer 3, an adsorption layer 4 and a top skeleton layer 5, a melt-blown non-woven fabric layer 2, and an electrostatic adsorption layer 3 , the adsorption layer 4 and the top framework layer 5 are sequentially arranged on the bottom framework layer 1 .

[0022] In this embodiment, the bottom skeleton layer 1 is made of long-fiber non-woven fabric, the weight of the bottom skeleton layer 1 is 15 g / ㎡, and its thickness is 0.10 mm. The long-fiber non-woven fabric is made of thermally bonded fiber filaments. The fiber filaments are a skin-wrapped structure consisting of a core of 55% by weight and a skin of 45%. The skin is made of polypropylene and titanium dioxide, and the core is PET. It is produced by melting, and the filaments are thermally bonded to form long-fiber non-woven fabrics. ...

Embodiment 2

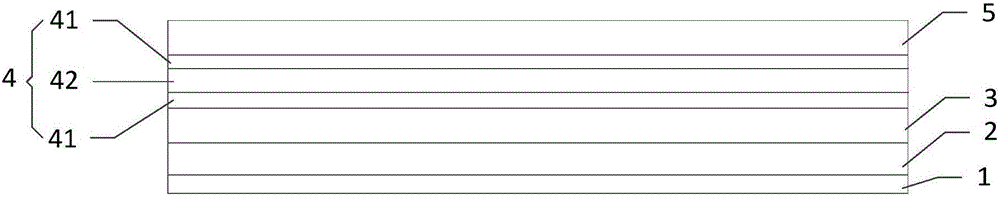

[0029] Such as figure 2 As shown, the air purification filter element in this embodiment includes a bottom skeleton layer 1, a melt-blown non-woven fabric layer 2, an electrostatic adsorption layer 3, an adsorption layer 4 and a top skeleton layer 5, a melt-blown non-woven fabric layer 2, and an electrostatic adsorption layer 3 , the adsorption layer 4 and the top framework layer 5 are sequentially arranged on the bottom framework layer 1 .

[0030] In this embodiment, the bottom skeleton layer 1 is long-fiber non-woven fabric, the weight of the bottom skeleton layer 1 is 25g / ㎡, and its thickness is 0.15mm. The long-fiber non-woven fabric is made of thermally bonded fiber filaments. The fiber filaments are a skin-wrapped structure consisting of a core of 55% by weight and a skin of 45%. The skin is made of polyethylene and calcium carbonate. The core is PET is produced by melting, and the filaments are thermally bonded to form long-fiber non-woven fabrics. The long-fiber no...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com