Air-water combined flushing system and method for high-sand-laden water direct drip irrigation capillary tube

A flushing system and capillary technology, applied in cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc., can solve the problems of poor hydraulic flushing effect and waste of water resources at the end of drip irrigation capillary, so as to reduce waste and improve sustainable Impact strength, effect of improving cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

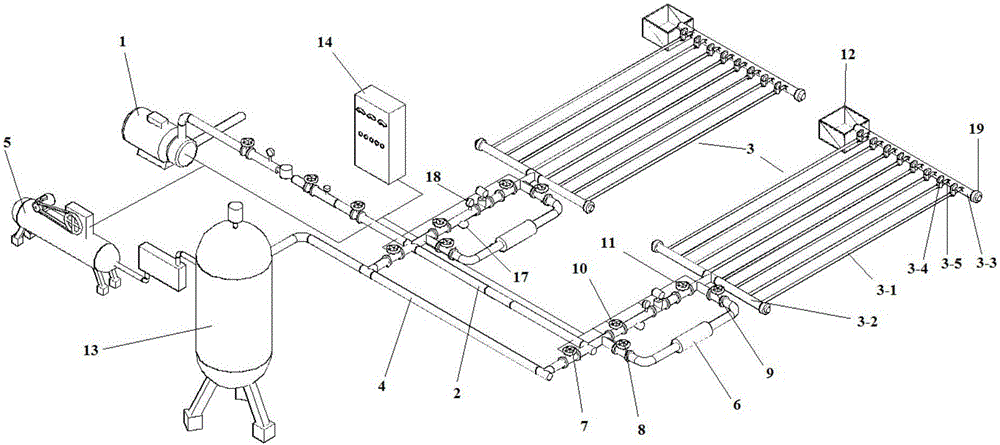

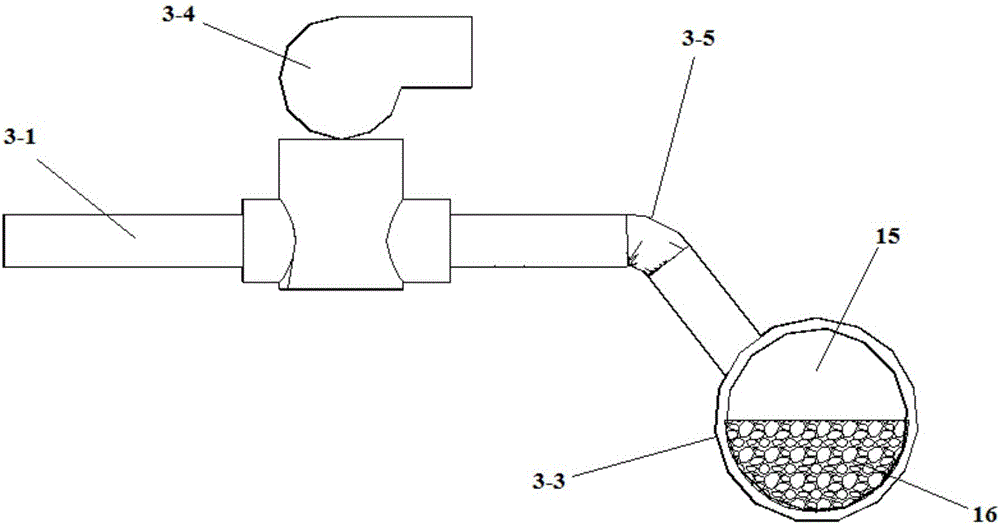

[0031] This embodiment provides a capillary air-water combined flushing system for direct drip irrigation of high-sand content water, such as Figure 1 to Figure 3 As shown, it includes a water pump 1, and the water pump 1 is connected to the water distribution pipe 3-2 of the drip irrigation belt 3 through the water delivery pipeline 2. The drip irrigation belt 3 includes a plurality of drip irrigation capillaries 3-1, and the plurality of drip irrigation capillaries 3-1 The head end of 1 is connected by water distribution pipe 3-2, and the tail ends of multiple drip irrigation capillary pipes 3-1 are connected by flushing and mud discharge pipe 3-3;

[0032] The water pipeline 2 between the water pump 1 and the water distribution pipe 3-2 communicates with the air compressor 5 through the gas pipeline 4 with the first valve 7;

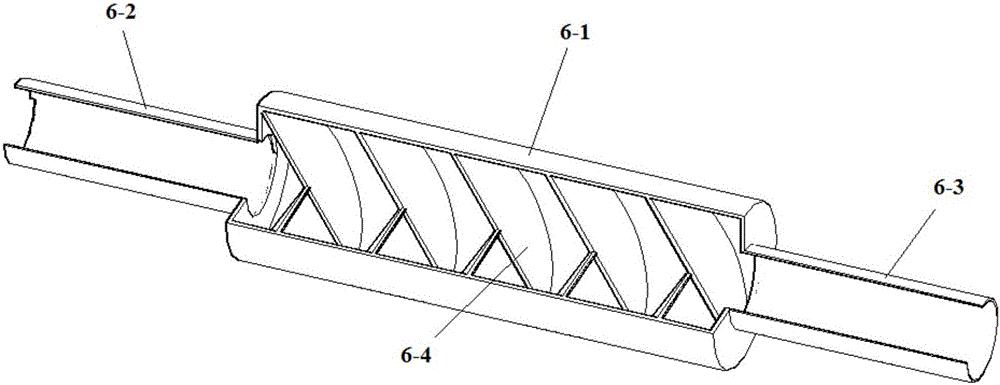

[0033] A gas-water turbulent mixer 6 is connected in parallel on the water pipeline 2 between the gas pipeline 4 and the water distribution pipe 3-2...

Embodiment 2

[0047] This embodiment provides a capillary air-water flushing method for direct drip irrigation of high-sand content water, the method adopts the capillary air-water flushing system for direct drip irrigation of high-sand content water as described in Example 1, wherein : the pressure in the air pipeline (4) is greater than the pressure in the water pipeline (2) during the air-water combined flushing process.

[0048] During the implementation of the above-mentioned flushing process, three specific parameters need to be controlled: the flushing time T of the system, the gas pressure P during the flushing process, and the flushing water head H. A complete flushing process of the drip irrigation system combined with air and water is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com