Working rotary table of sponge horizontal cutting machine

A technology of flat cutting machine and turntable, which is applied in the direction of metal processing, etc. It can solve the problems of not being suitable for complex structure sponge cutting, inflexible movement of the worktable, and low processing efficiency, etc., to achieve simple structure, stable and reliable transmission, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

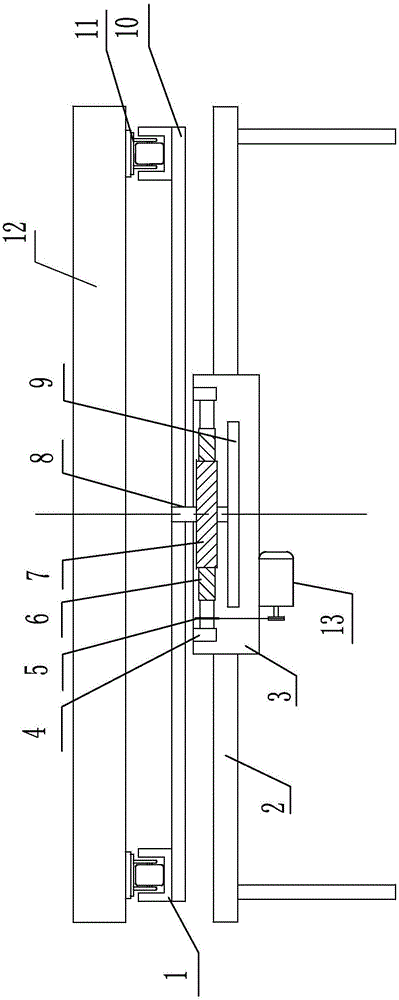

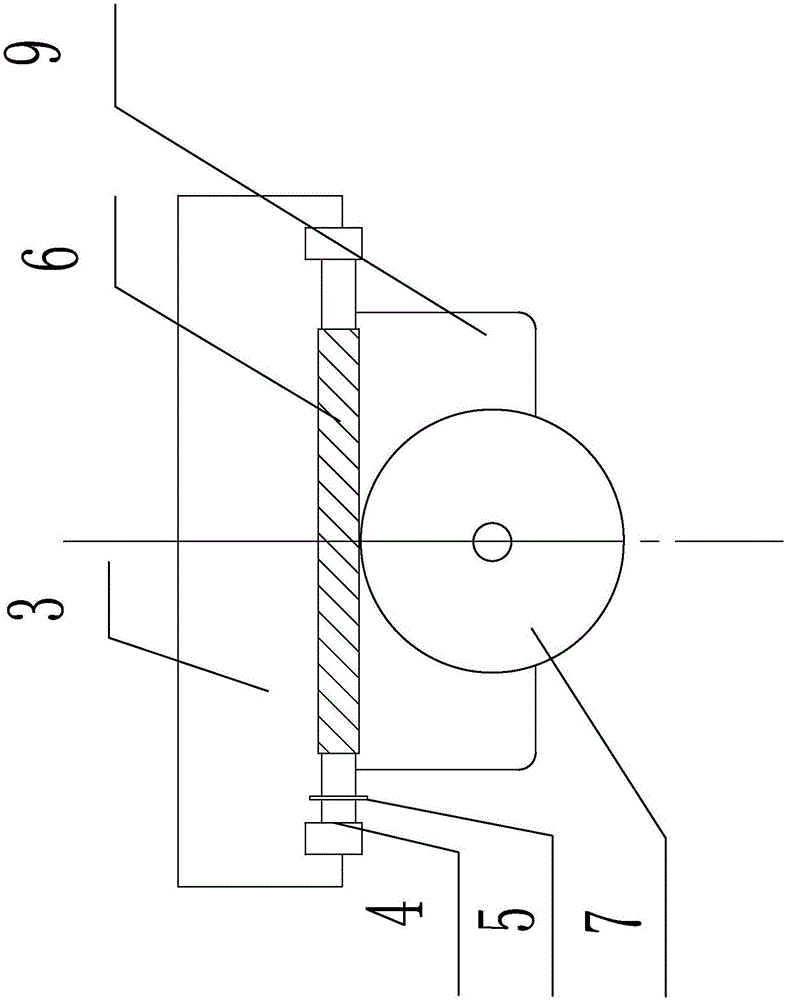

[0018] as attached figure 1 , 2 shown

[0019] The invention provides a working turntable of a sponge flat cutting machine, including a guide rail 1, a bracket 2, a box body 3, a connecting piece 4, a sprocket 5, a worm 6, a turbine 7, a rotating shaft 8, a fixed frame 9, a turntable 10, a roller 11, The workbench 12 and the motor 13; the box body 3 is fixedly connected to the upper end of the bracket 2, and a connecting piece 4 is fixedly connected to both sides of the upper end of the box body 3, and the two sides of the worm screw 6 are respectively arranged in the bearing holes in the connecting piece 4, and the turbine 7 is fixed Connected to the rotating shaft 8, the motor 13 is fixedly connected to the lower end of the box body 3 via bolts, a number of rollers 11 are respectively arranged on both sides of the lower end of the workbench 12, a fixed frame 9 is arranged on the lower side of the box body 3, and a worm screw is arranged on the inner side of the box body 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com