Lightweight aggregate cement concrete mixing device and mixing method thereof

A technology for cement concrete and light aggregates, which is applied in unloading devices, clay preparation devices, chemical instruments and methods, etc., can solve the problems of uneven cement mixing, broken light aggregates, cement agglomeration, etc., to ensure stable quality. The effect of stability, low weight and guaranteed integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

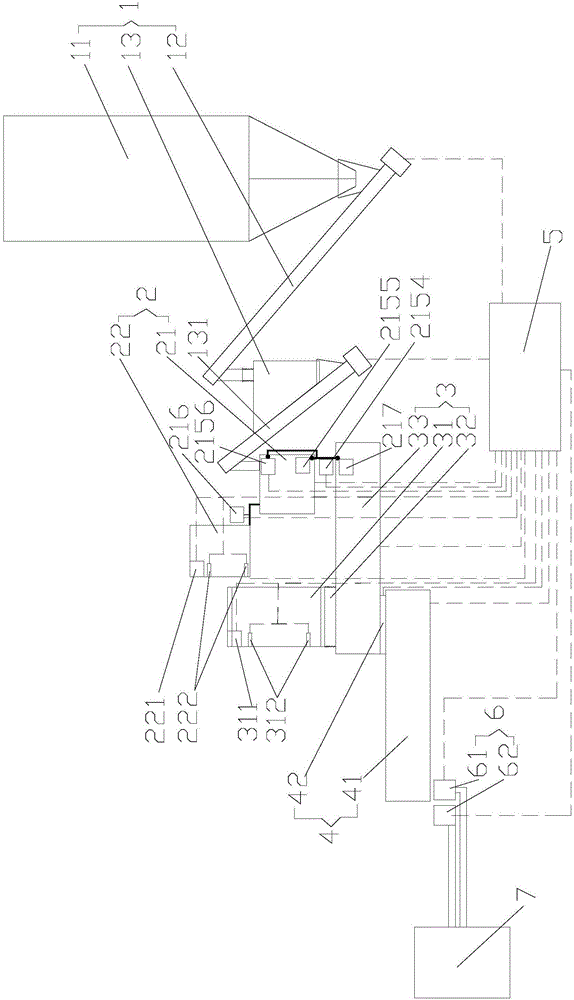

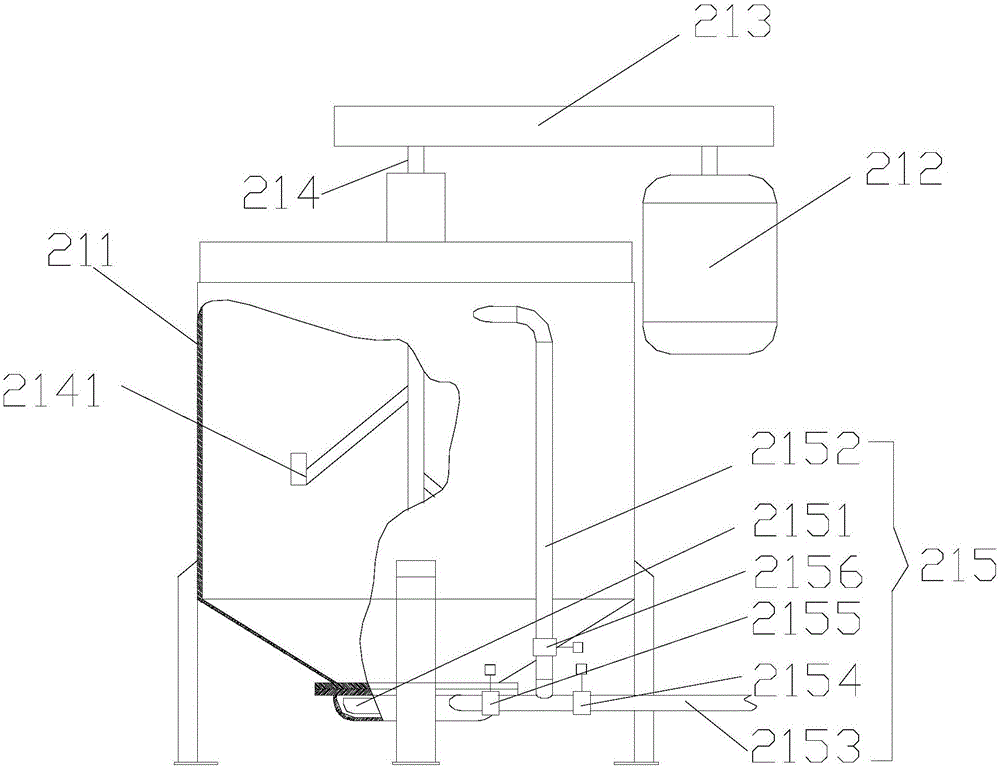

[0032] Attached below in conjunction with the manual Figure 1-2 The technical solution of the present invention is described in detail.

[0033] like Figure 1-2 As shown, the light-weight aggregate cement concrete mixing device according to the present invention comprises a cement feeding mechanism 1, a cement slurry-making mechanism 2 and a light-weight aggregate mixing mechanism 3 which are connected in sequence. The mixing speeds of the cement pulping mechanism 2 and the light aggregate mixing mechanism 3 are sequentially reduced. The lightweight aggregate cement concrete mixing device further includes a concrete continuous mixing mechanism 4 which is connected to the lightweight aggregate mixing mechanism 3 and has a lower mixing speed than the lightweight aggregate mixing mechanism 3 . The cement pulping mechanism 2 is a cement pulping mechanism with a stirring speed of 800-1000 rpm, the light aggregate mixing mechanism 3 is a light aggregate mixing mechanism with a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com