Efficient controllable hot press forming device

A thermoforming and controllable technology, used in punching machines, presses, manufacturing tools, etc., can solve the problems of real-time monitoring of inoperable conditions, high manufacturing and operating costs, and complex overall structure of the device, ensuring long-term Efficient and stable operation, shortening the time of hot pressing, and prompting the effect of remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

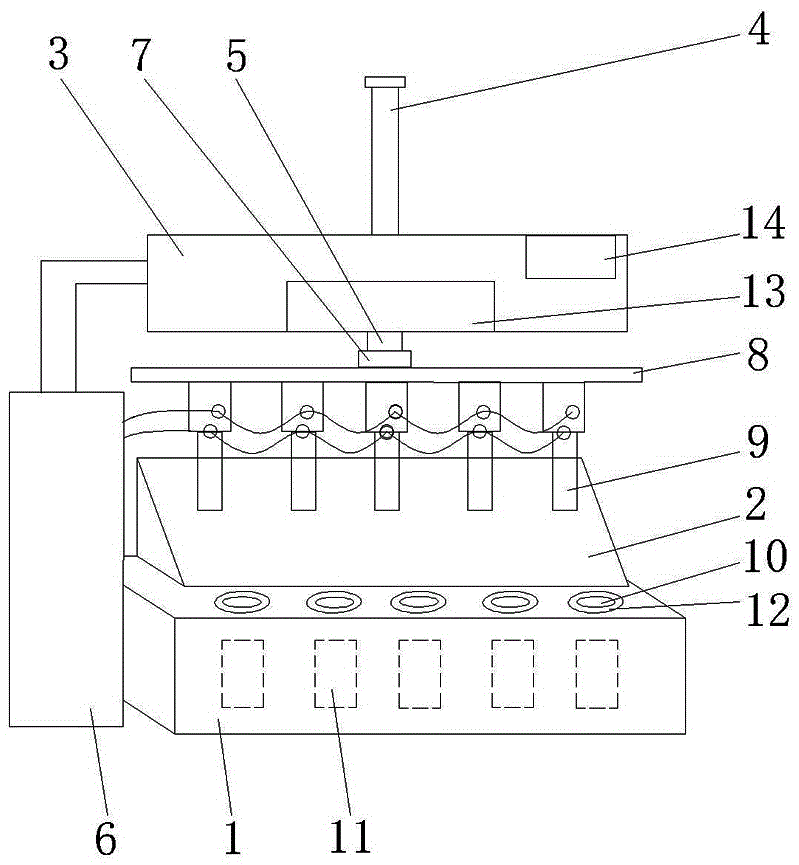

[0025] Such as figure 1 As shown, a high-efficiency controllable hot press forming device in this embodiment includes: a body 1, a feeding box 2, a control box 3, a hydraulic cylinder 4, a slide rod 5, a motor box 6, a fixing seat 7, and a support 8. Upper mold 9 , heating tank 10 , lower mold 11 , heat insulation ring 12 , control panel 13 and display panel 14 .

[0026] The connection relationship of the above-mentioned components is as follows: the feeding box 2 is slidingly connected to the upper surface of the fuselage 1, the front end of the fuselage 1 is provided with five heating tanks 10, and the bottom of the feeding box 2 is provided with a heating tank 10 corresponding to the heating tank 10. There are five through holes; the inside of the heating tank 10 is correspondingly provided with a lower mold 11, the fuselage 1 is fixedly connected with the upper control box 3 through a column, and the hydraulic cylinder 4 is connected with the slide bar 5 in the control bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com