Winding type tire belted layer structure

A belt layer and tire technology, applied in the field of wound tire belt layer structure, can solve the problems of tire belt layer detachment, affecting the service life of tires, and emptying, etc., to reduce tire heat generation, improve durability performance, The effect of reducing mutual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

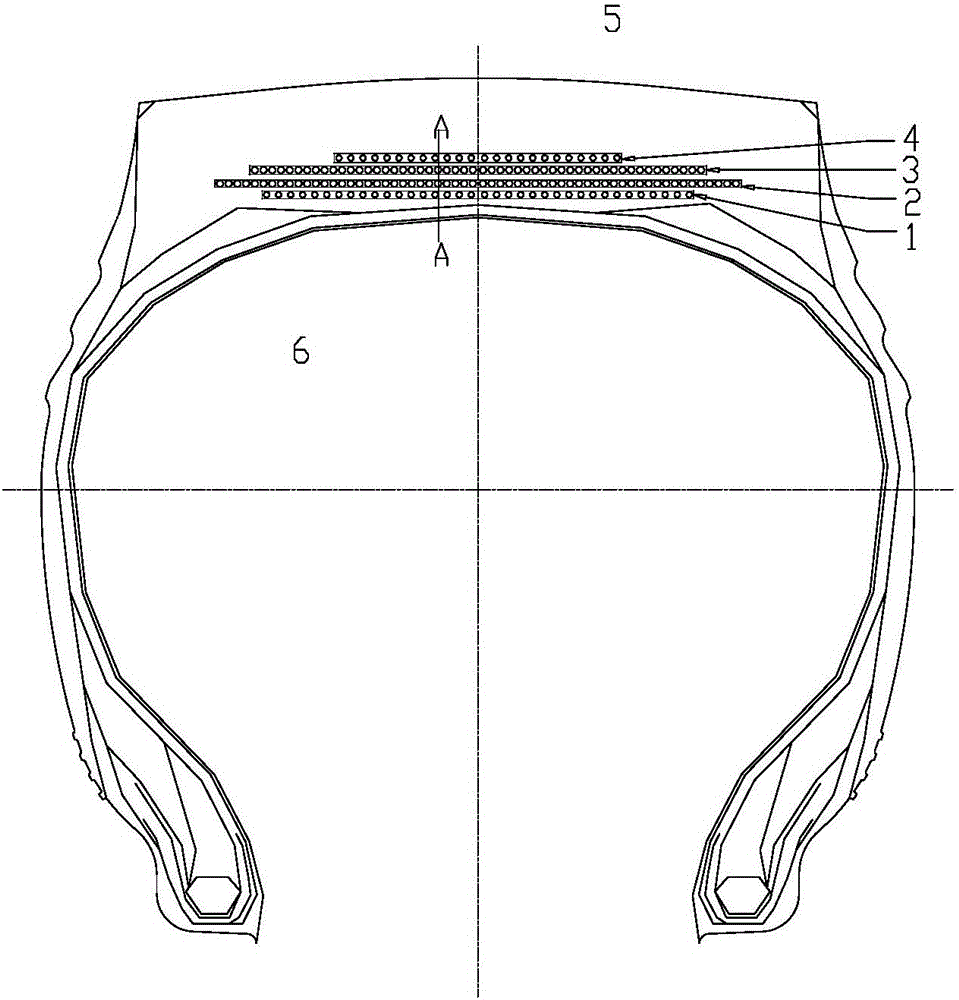

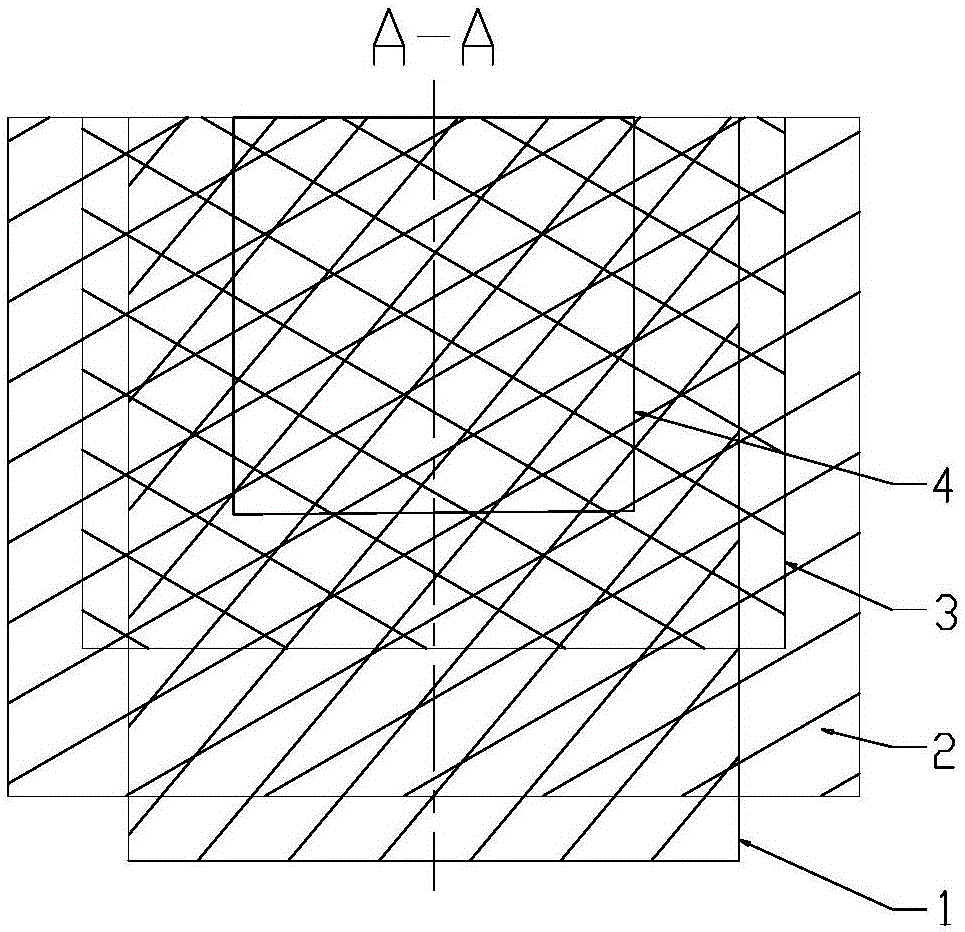

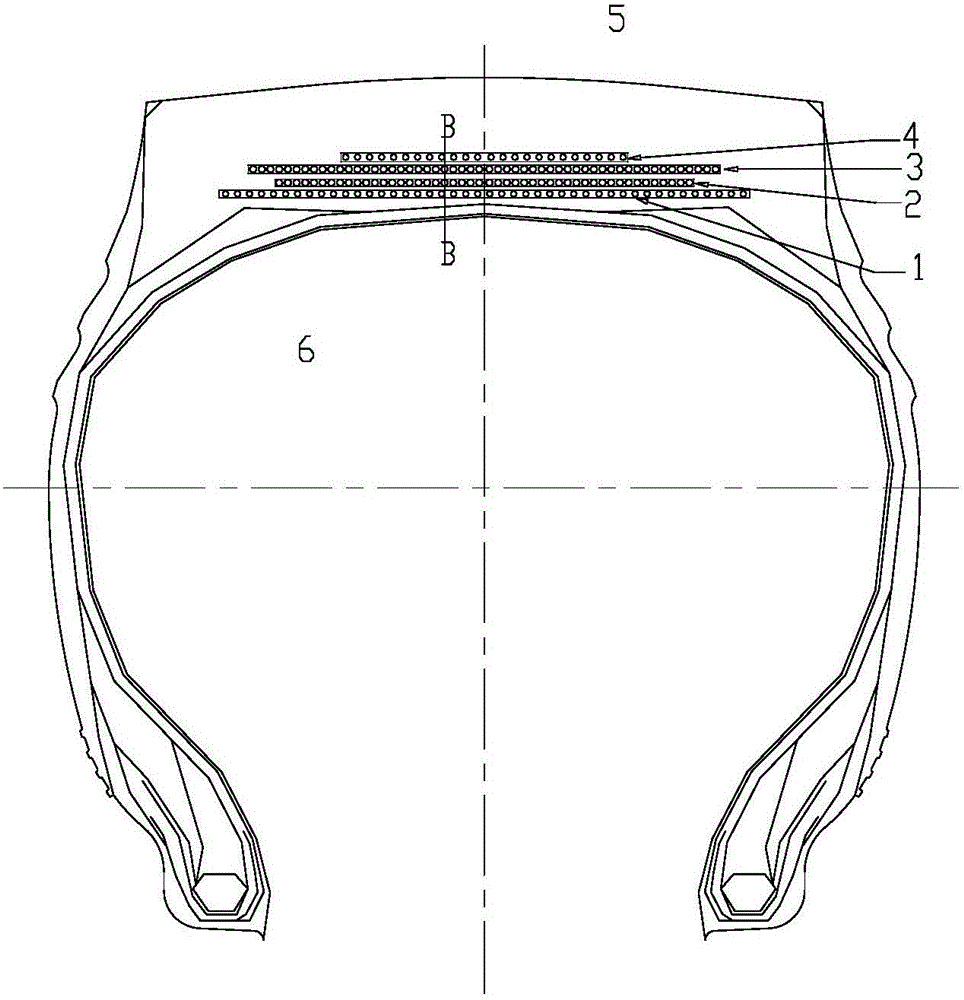

[0020] image 3 , 4 Among them, the first belt layer 1, the second belt layer 2, the third belt layer 3, the fourth belt layer 4, the tread 5, the carcass 6, etc. are included.

[0021] Such as image 3 , 4 As shown, the present invention is a winding tire belt structure, including a carcass 6, on which at least a first belt layer 1 and a second belt layer 2 are sequentially attached, and the second belt layer The belt layer 2 includes three steel wires spirally wound on the first belt layer 1 and the rubber coating used to connect the three steel wires. During the winding process of the three steel wires, the gap between two adjacent coils of steel wires is 0~2mm. The angle between the wound steel wire and the center line of the tread 5 is 1°-3°, and the width of the second belt layer 2 is smaller than the width of the first belt layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com