A pneumatic self-generating semi-trailer suspension device

A suspension device, semi-trailer technology, applied in auxiliary drive devices, control devices, suspensions, etc., can solve problems such as hidden dangers of driver's personal safety, easy damage to spring steel plates, damage to leaf springs, etc., so as to ensure personal safety and avoid overloading. , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with the embodiments.

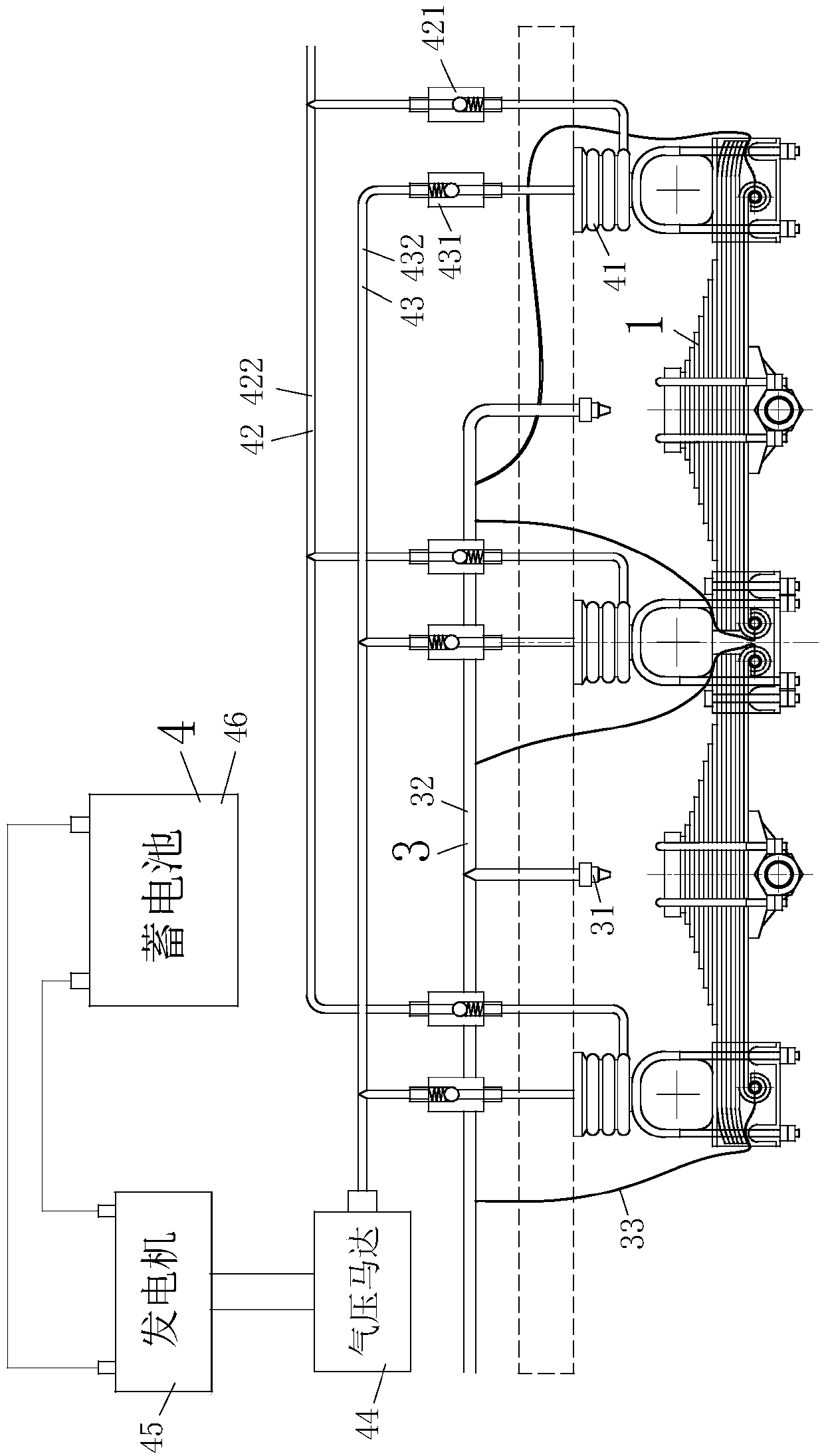

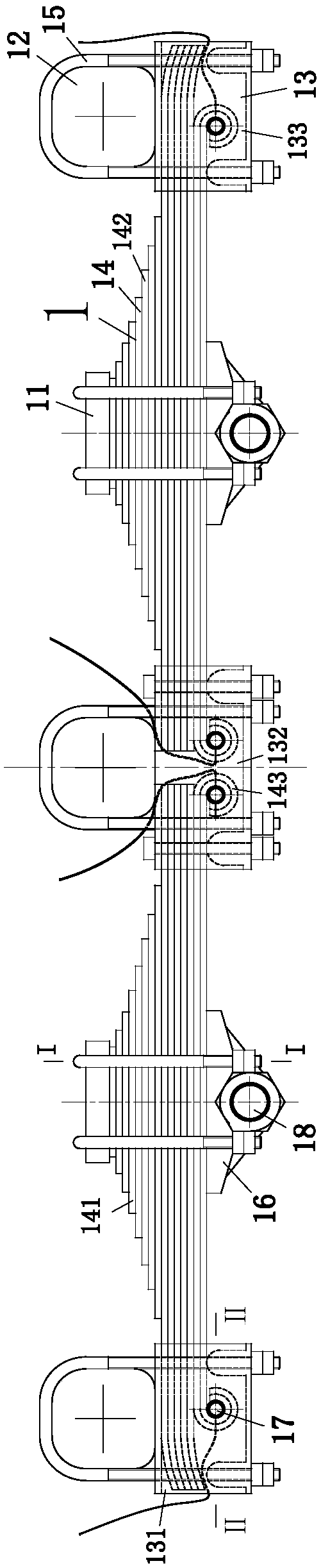

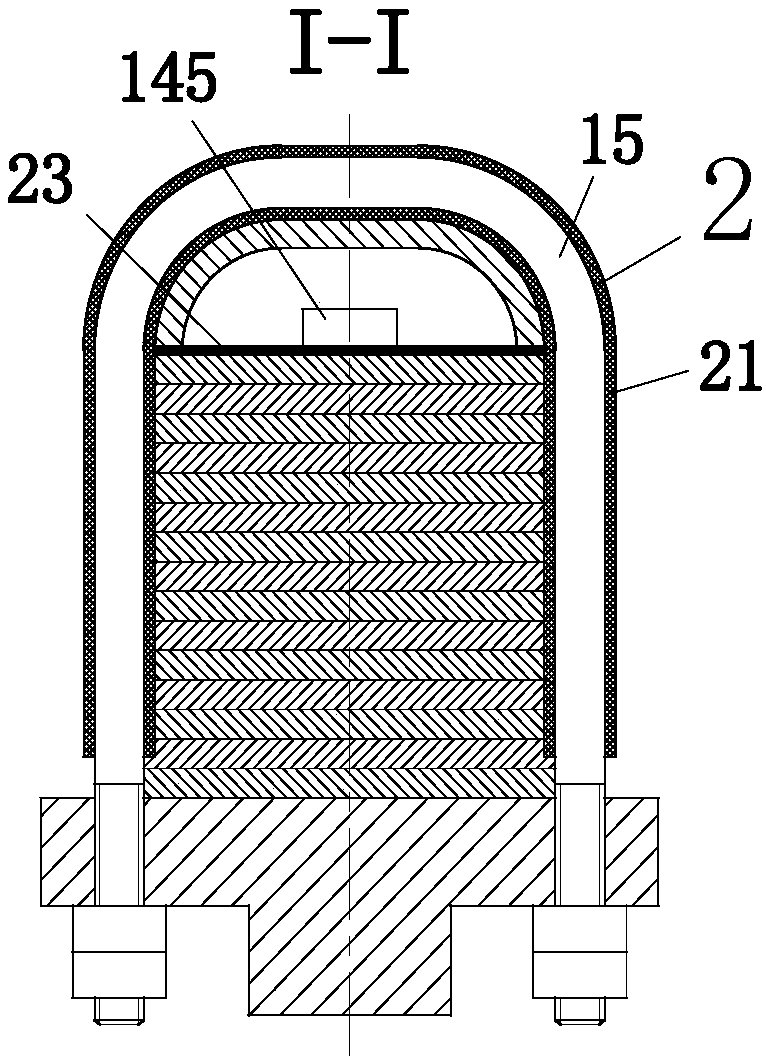

[0027] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, a pneumatic self-generating semi-trailer suspension device of the present invention includes a suspension main body 1, a protection main body 2, a cooling main body 3 and a power generation main body 4; the suspension main body 1 includes a suspension bracket 11, an axle 12 , leaf spring support 13, leaf spring 14, U-bolt 15, support seat 16, bearing pin 17 and balance shaft 18.

[0028] The leaf spring 14 includes a front spring 141 and a rear spring 142, the front and rear ends of the front spring 141 and the rear spring 142 are provided with roll ears 143 as pin holes, and each roll ear 143 is provided with There is a liquid inlet hole 144, the number of the suspension brac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com