Front windshield assembly and vehicle using front windshield assembly

A technology for front windshields and components, applied to windshields, vehicle components, superstructures, etc., can solve problems such as prone to collisions and collisions, and personal threats to drivers, so as to reduce the risk of traffic accidents and eliminate driving hazards. Effects of dead zone, high strength and stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

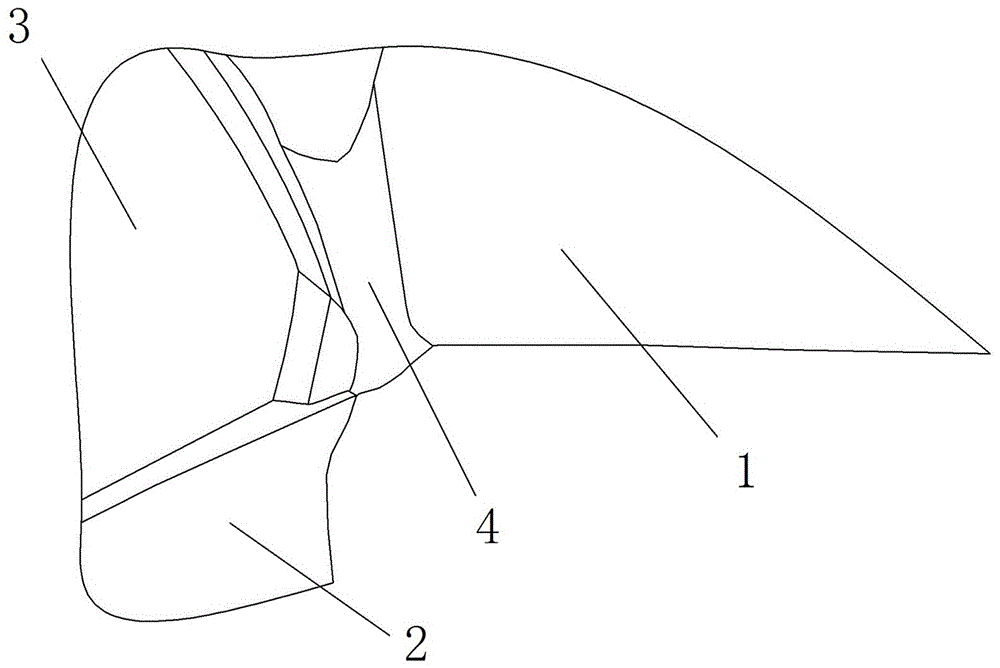

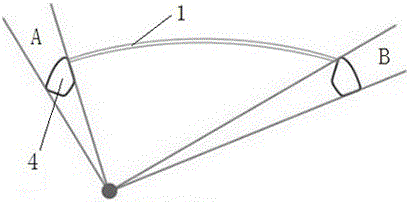

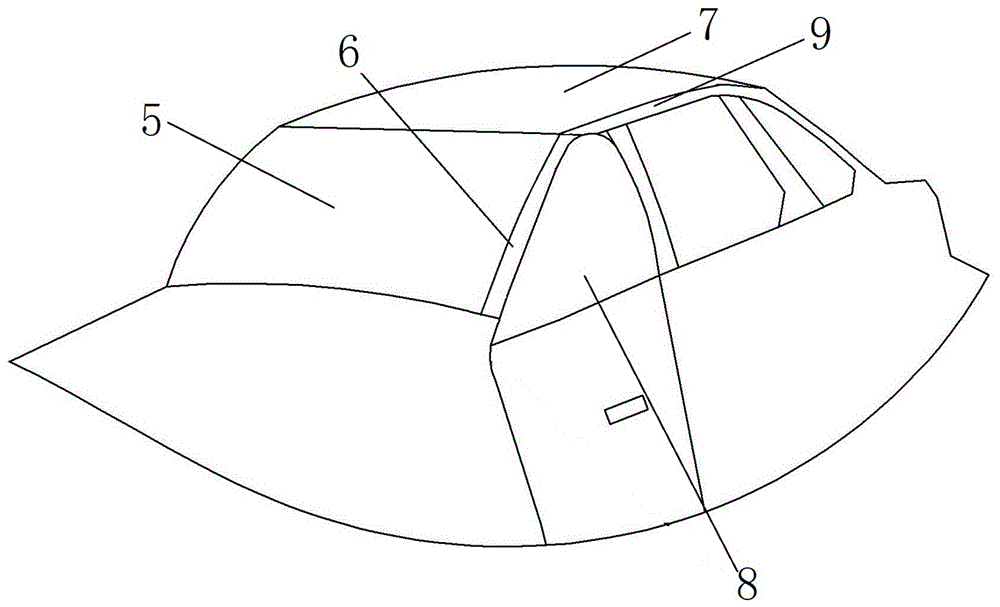

[0018] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings. Specific embodiment one of the vehicle of the present invention, such as image 3 As shown, it includes a vehicle body, a roof panel 7, a roof frame 9 and a front windshield assembly, and the front windshield assembly includes a front windshield 5 and an A-pillar 6 integrally formed with the front windshield 5, and the A-pillar 6 is two One, respectively positioned at the left and right sides of the front windshield 5, the front windshield 5 and the A-pillar 6 are all made of transparent material, and the transparent material is bulletproof glass in the present embodiment. The two A-pillars have the same structure, and one of them is taken as an example to describe in detail below. In order to increase the rigidity of the A-pillar 6, the A-pillar 6 and the front windshield 5 are connected by an arc transition, and the thickness of the A-pillar 6 is greater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com