Electric vehicle high-voltage distribution control cabinet packaged with DC module and charging module

A charging module and high-voltage power distribution technology, which is applied to electric vehicles, current collectors, vehicle components, etc., can solve the problems of low integration, cluttered wiring harnesses, and single functions, so as to solve the problems of cluttered wiring harnesses, improve heat dissipation, and occupy small space effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and embodiment, further elaborate the present invention.

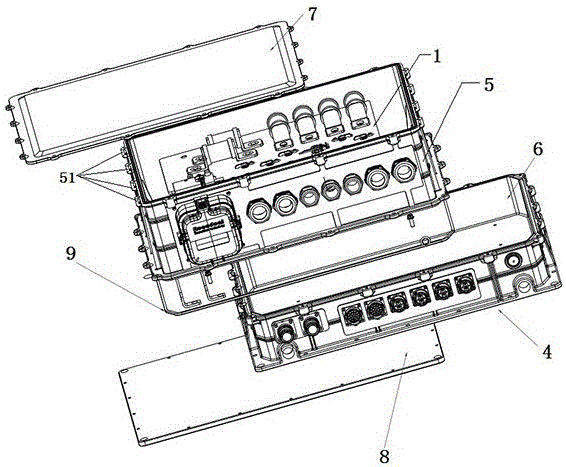

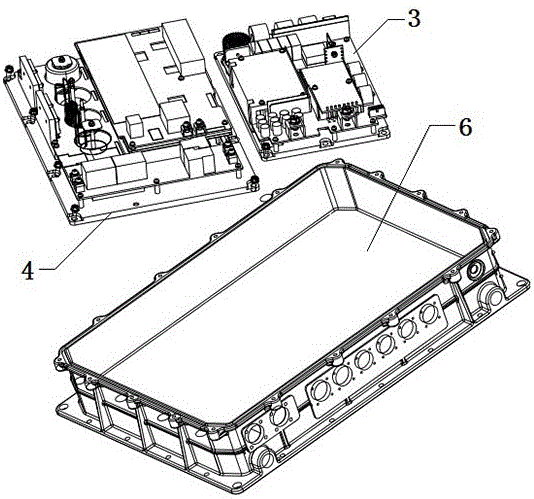

[0029] Such as Figure 1-Figure 2 Shown is a schematic diagram of structural decomposition of the present invention. An electric vehicle high-voltage power distribution control box packaged with a DC module and a charging module, including a high-voltage power distribution module 1, a charging module 2, a DC module 3, a water cooling mechanism 4, an upper frame 5, a lower frame 6, an upper cover 7, Lower cover 8, sealing ring 9, water cooling mechanism 4, upper frame 5, lower frame 6, upper cover 7, lower cover 8, sealing ring 9 (for charging module 2 and DC module 3, see figure 2 ).

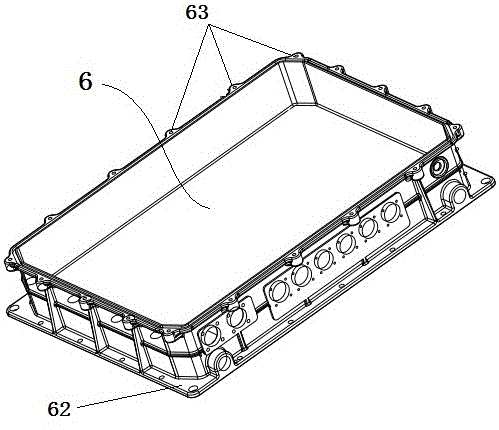

[0030] The upper frame 5 and the lower frame 6 are respectively in the shape of a square shell without a top surface; the length and width of the upper frame 5 are respectively equal to the length and width of the lower frame 6; the four sides of the upper frame 5 and the lower fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com