Plate and its manufacturing method

A manufacturing method and technology of plate-shaped parts, which are applied to household components, other household appliances, transportation and packaging, etc., can solve problems such as cracking of clad steel pipes, and achieve the effect of eliminating hidden dangers in production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so as to better understand the purpose, features and advantages of the present invention. It should be understood that the embodiments shown in the drawings are not intended to limit the scope of the present invention, but only to illustrate the essence of the technical solutions of the present invention.

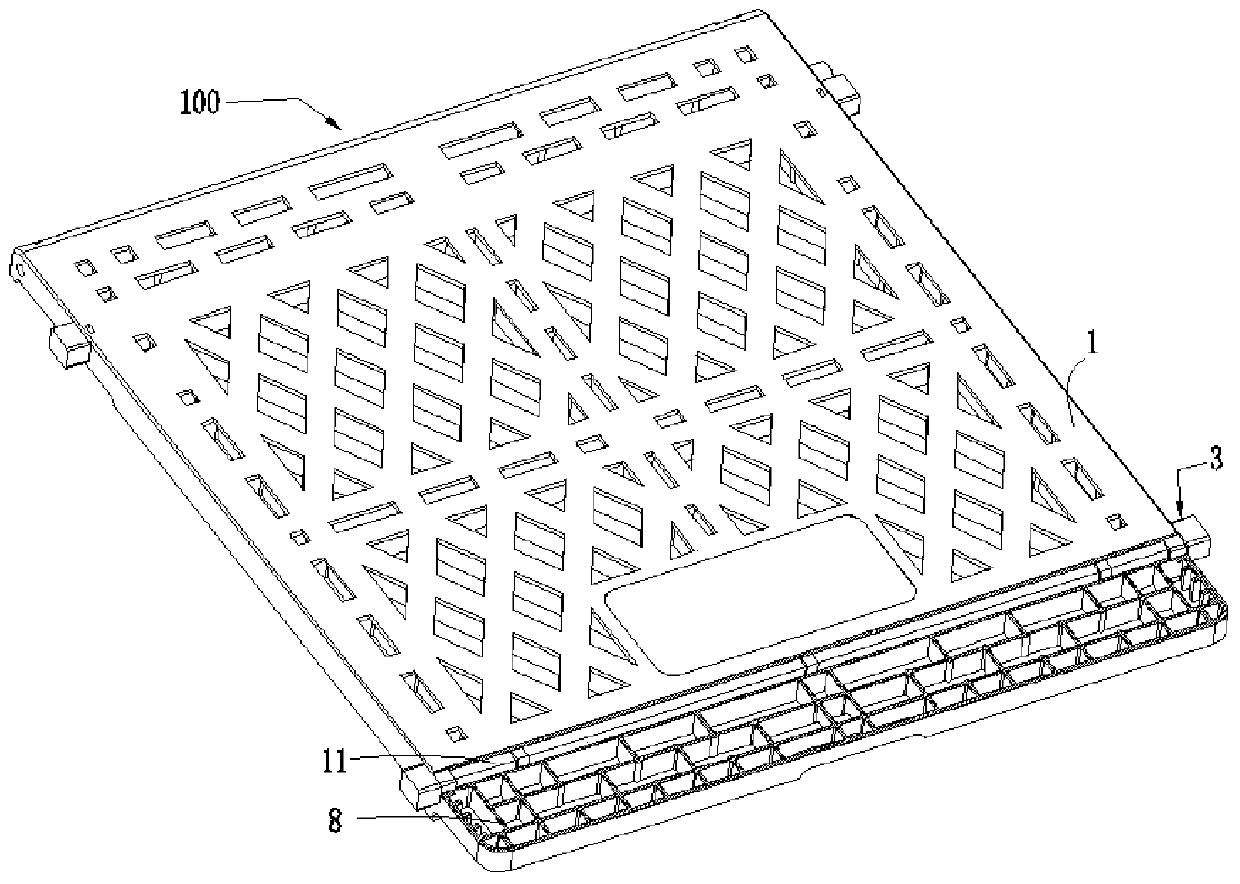

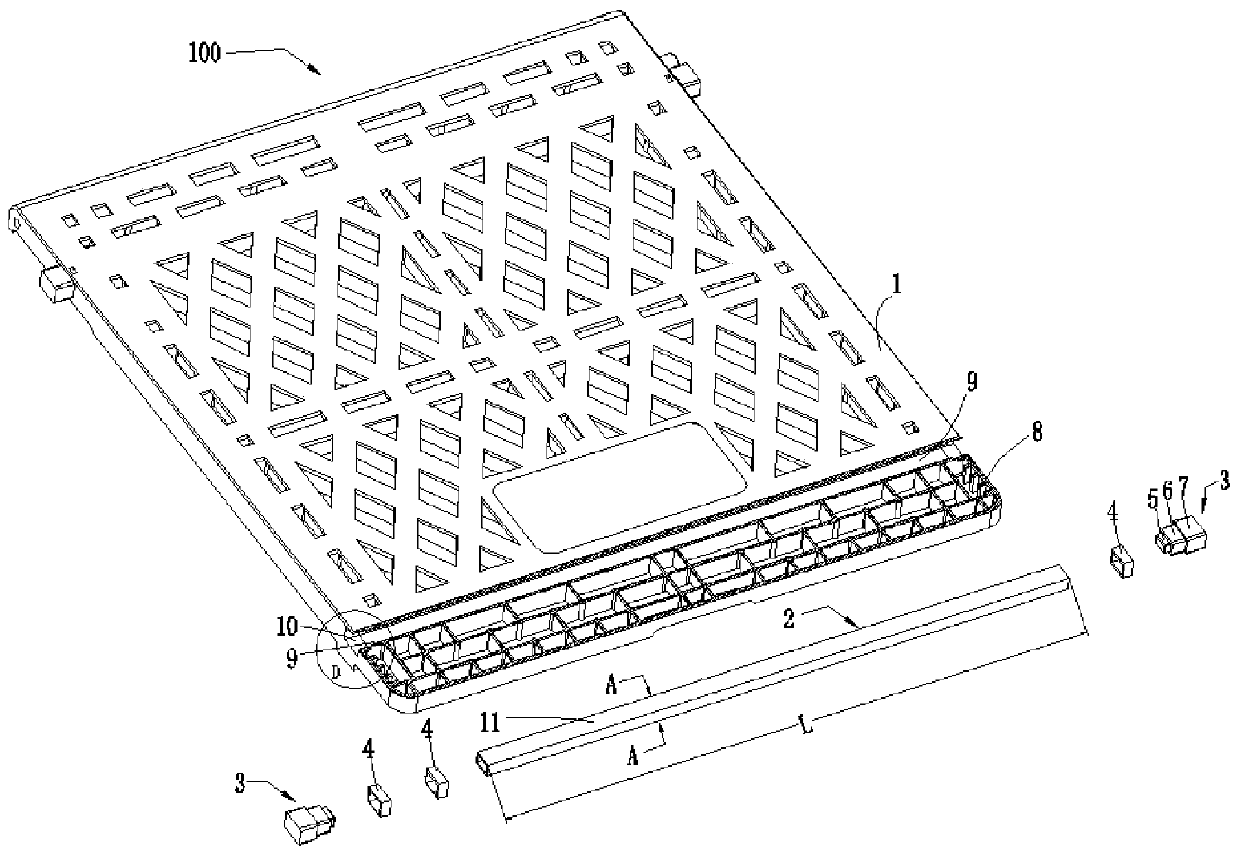

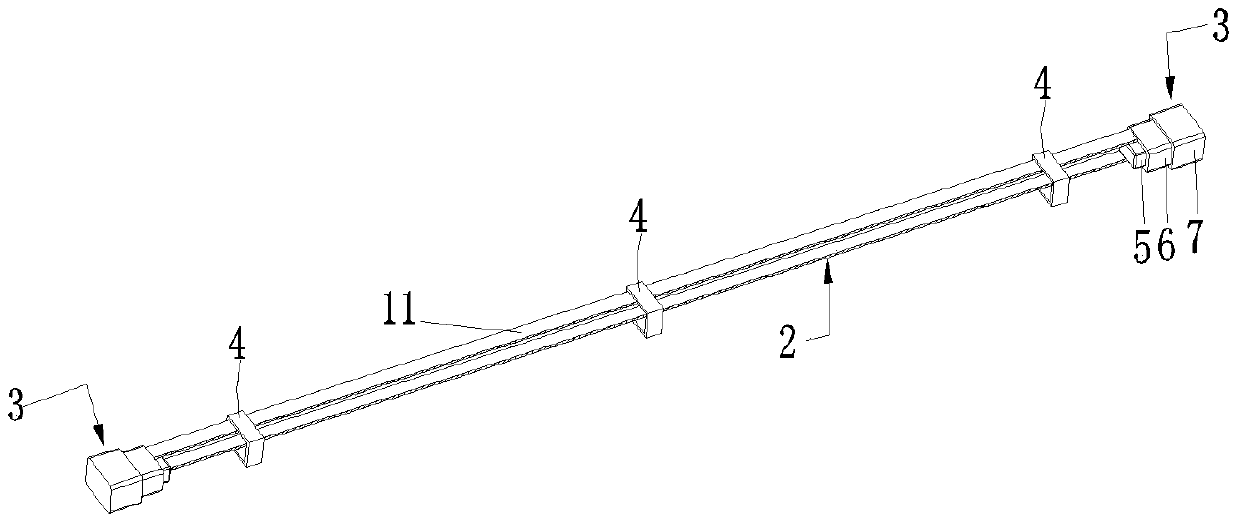

[0076] Figure 1-2 A schematic structural view of a plate-shaped member 100 according to an embodiment of the present invention is shown. The plate-shaped member 100 includes a plate-shaped main body 1 and a steel pipe 2 built in the plate-shaped main body 1, and the steel pipe 2 serves as a reinforcement. Both ends of the steel pipe 2 are detachably connected with plugs 3 for blocking the steel pipe. Plug 3 protrudes to a predetermined length Lc at both ends of steel pipe 2 (such as Figure 5 shown). The outer circumference of the steel p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com