Oxygen injection calcinator for production of zinc oxide

A zinc oxide and calcination furnace technology, applied in the direction of zinc oxide/zinc hydroxide, etc., can solve the problems of high impurity content in zinc oxide, small contact area, and low production efficiency, so as to avoid the generation of impurities, increase the contact area, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing:

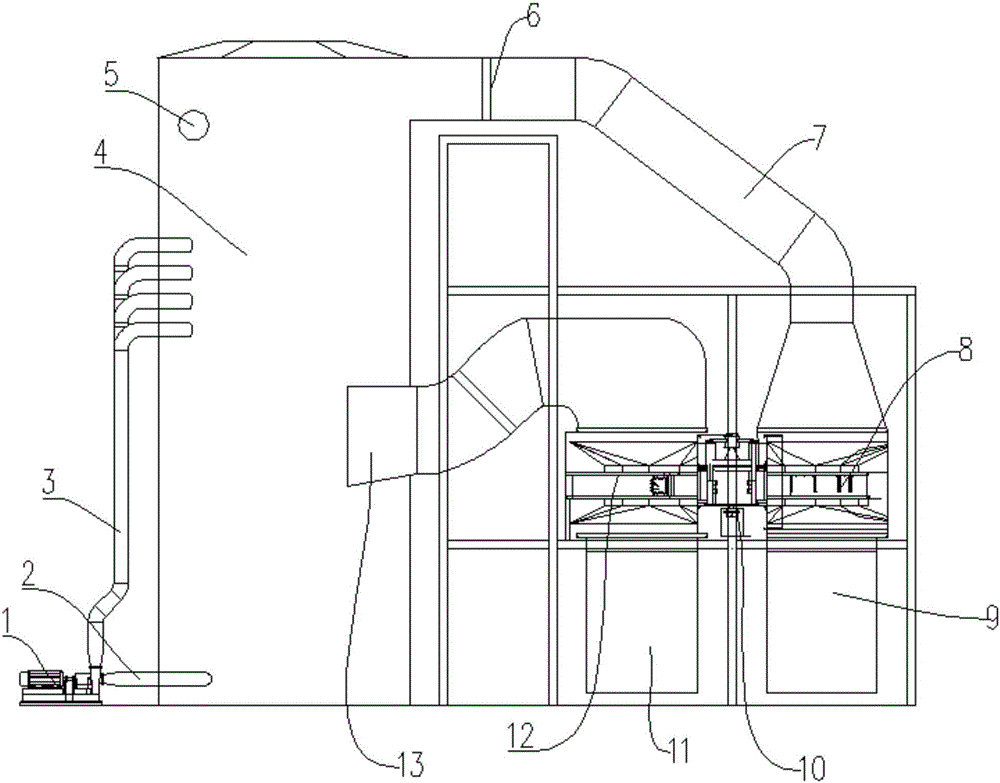

[0015] Such as figure 1 As shown, an oxygen-injected calciner for zinc oxide production includes a motor-1, a combustion chamber 4, a cyclone collector 8 and a feeder 12, an oxygen injection pipe 3 is arranged above the motor-1, and the motor-1 passes through the gas The injection pipe 2 communicates with the combustion chamber 4, a thermometer 5 is arranged above the combustion chamber 4, a cyclone collector 8 is arranged between the delivery pipe 7 and the zinc oxide storage chamber 9, and the delivery pipe 7 is connected with the combustion chamber 4 through the filter interlayer 6, A zinc powder storage chamber 11 is installed below the feeder 12 , the feeder 12 is connected with the combustion chamber 4 through a zinc powder injection pipe 13 , and a motor two 10 is arranged between the feeder 12 and the cyclone collector 8 .

[0016] In the above structure, the gas a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com