Recycled monomer processing device for polyvinyl chloride production and method for processing recycled monomer for polyvinyl chloride production

A polyvinyl chloride and processing device technology, applied in the field of recycled monomers for polyvinyl chloride production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

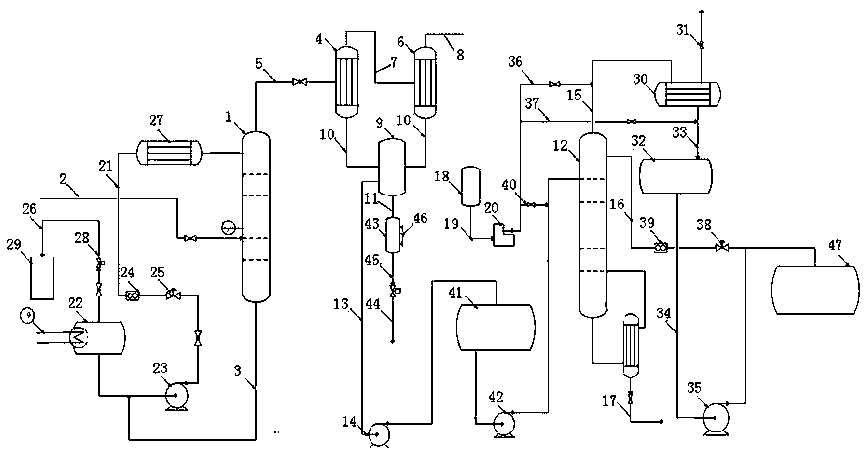

[0024] Embodiment 1, as attached figure 1As shown, the recovered monomer treatment device for polyvinyl chloride production includes an alkali washing tower 1, a recovered primary condenser 4, a recovered secondary condenser 6, a liquid seal tank 9, a recovered monomer rectifying tower 12, and a recovered monomer Delivery pump 14 and polymerization inhibitor storage tank 18; Gas phase recovery monomer main pipe 2 is fixedly installed at the tower body bottom of alkali washing tower 1, and lye inlet pipeline 21 is fixedly installed at the tower body top of alkali washing tower 1, and The tower bottom of the alkali washing tower 1 is fixedly installed with a lye outlet pipeline 3, and a recovery monomer outlet pipeline 5 is fixedly installed between the tower top of the alkali washing tower 1 and the heat medium feed port of the recovery primary condenser 4 A condenser connection pipeline 7 is fixedly installed between the gas outlet at the top of the recovery primary condenser ...

Embodiment 2

[0025] Embodiment 2, as the optimization of above-mentioned embodiment, as attached figure 1 As shown, the recovered monomer treatment device for polyvinyl chloride production also includes an alkali preparation tank 22 and an alkali washing tower circulation pump 23; Together, an alkali washing tower circulation pump 23 is fixedly installed on the alkali liquor inlet tower pipeline 21, and an alkali liquor flowmeter is fixedly installed on the alkali liquor inlet tower pipeline 21 between the alkali washing tower circulation pump 23 and the alkali washing tower 1 respectively. 24 and lye flow regulating valve 25, the other end of the lye preparation tank 22 and the alkali washing tower circulation pump 23 between the lye preparation tower pipeline 21 and the other end of the lye discharge tower pipeline 3 is fixedly installed together; the lye preparation tank 22 The upper end of the lye preparation tank exhaust pipeline 26 is fixedly installed. The lye in the lye washing to...

Embodiment 3

[0026] Embodiment 3, as the optimization of embodiment 2, as attached figure 1 Shown, on the alkali lye inlet tower pipeline 21 after alkali lye flowmeter 24 and alkali lye flow control valve 25, be fixedly installed with alkali lye preheater 27, the cooling of alkali lye inlet tower pipeline 21 and lye preheater 27 The medium inlet and outlet are fixedly installed together; or / and, a self-control valve 28 is fixedly installed on the lye preparation tank exhaust pipeline 26; or / and, the other end of the lye preparation tank exhaust pipeline 26 is located at the lye security receiving cylinder 29 Inside. The lye preheater 27 can cool down and heat up the circulating lye.

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com