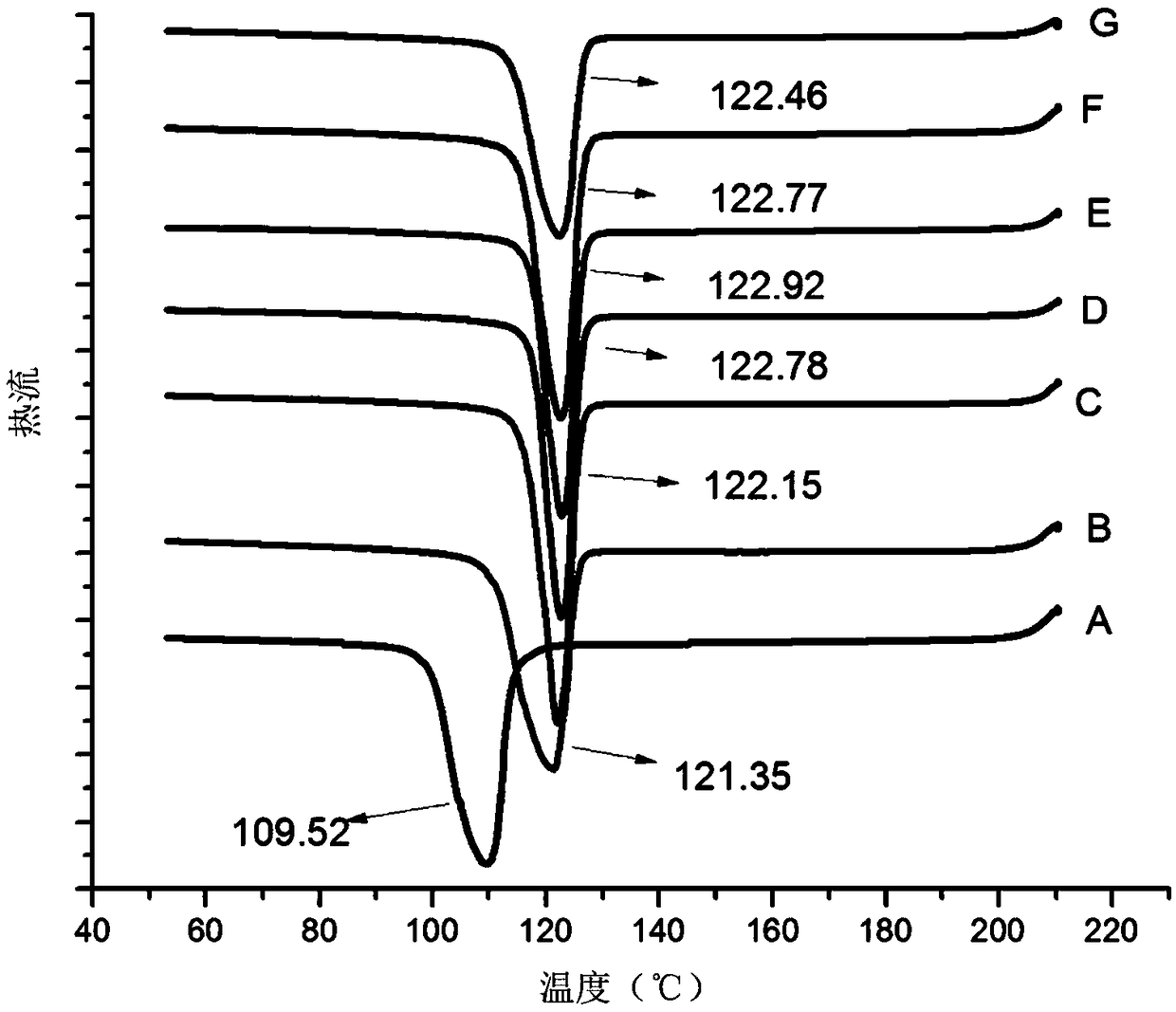

A kind of rare earth polypropylene stiffening nucleating agent and preparation method thereof

The technology of polypropylene and nucleating agent is applied in the field of rare earth polypropylene stiffening nucleating agent and its preparation, which can solve the problems of high low temperature brittleness, poor compatibility between inorganic powder and polypropylene resin, and low thermal deformation temperature. , to achieve the effect of improving bending performance, good dispersion effect and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

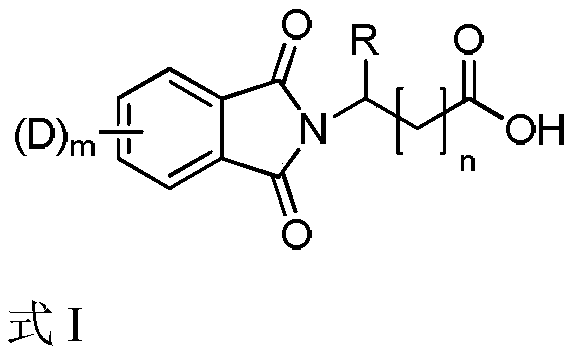

Method used

Image

Examples

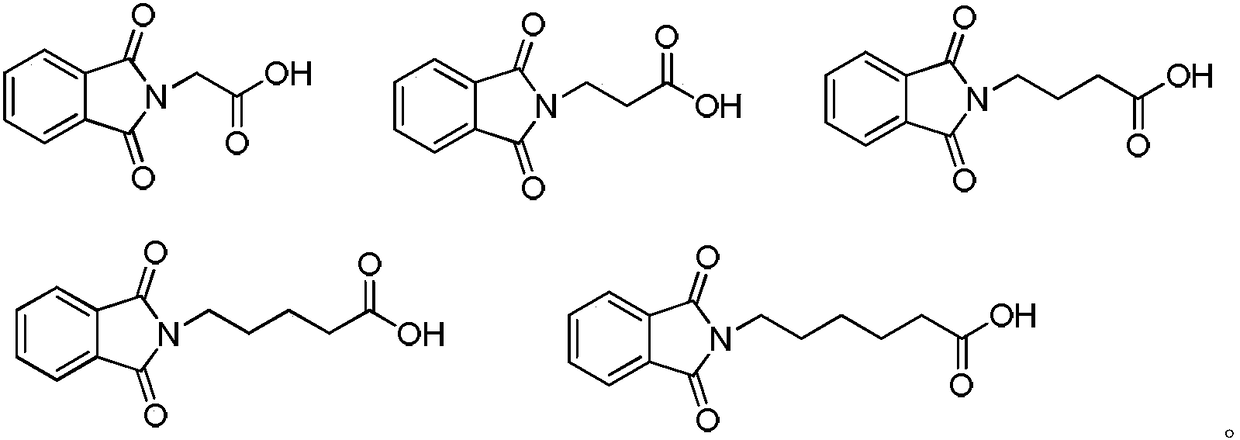

Embodiment 1

[0035] Glycine and phthalic anhydride were weighed at a molar ratio of 1:1.1, fully ground in a mortar, mixed evenly, transferred to a three-necked flask, stirred and melted in an oil bath at 135°C for 1 hour, and transferred after the reaction. recrystallization, suction filtration, and vacuum drying to obtain phthalylglycine;

[0036] Then weigh a certain amount of phthaloylglycine, add an appropriate amount of ethanol and water to dissolve it, adjust the pH to 6 with sodium hydroxide, transfer it to a three-necked bottle, and slowly add an aqueous solution of lanthanum nitrate dropwise while stirring in a water bath at 50°C (The molar ratio of lanthanum nitrate to phthalylglycine is 1:3), react for 4 hours, cool to room temperature, filter the product with suction, wash, and vacuum-dry to constant weight to obtain lanthanum phthalylglycinate as polypropylene Just nucleating agent.

Embodiment 2

[0038] Weigh 3-aminopropionic acid and phthalic anhydride at a molar ratio of 1:1.2, grind them thoroughly in a mortar, mix them evenly, transfer them to a three-necked flask, and stir and melt them in an oil bath at 140°C for 1 hour. The obtained product was transferred, recrystallized, suction filtered, and vacuum-dried to obtain 3-(phthalimido)propionic acid;

[0039] Then weigh a certain mass of 3-(phthalimido)propionic acid, add appropriate amount of ethanol and water to dissolve, adjust the pH to 7 with sodium hydroxide, transfer it to a three-necked flask, and stir in a water bath at 50°C Slowly add aqueous solution of lanthanum chloride dropwise (the molar ratio of lanthanum chloride to 3-(phthalimido)propionic acid is 1:3.5), react for 4 hours, cool to room temperature, filter the product with suction, wash and dry in vacuum To constant weight, 3-(phthalimido) lanthanum propionate was obtained as a stiffening nucleating agent for polypropylene.

Embodiment 3

[0041] Weigh γ-aminobutyric acid and phthalic anhydride at a molar ratio of 1:1.2, grind them thoroughly in a mortar, mix them evenly, transfer them to a three-necked flask, and stir and melt them in an oil bath at 145°C for 2 hours. After the reaction, the obtained Product transfer, recrystallization, suction filtration, and vacuum drying to obtain phthalamide butyric acid;

[0042] Then weigh a certain amount of phthaloyl aminobutyric acid, add an appropriate amount of methanol and acetone to dissolve, adjust the pH to 6 with triethylamine, transfer it to a three-necked flask, and slowly add chlorinated Cerium ethanol solution (the molar ratio of cerium chloride to phthalamide butyric acid is 1:3.5), react for 4 hours, cool to room temperature, filter the product with suction, wash, and vacuum dry to constant weight to obtain phthalamide Cerium butyrate acts as a stiffening nucleating agent for polypropylene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com