Novel tire sealing composite material containing maleic resin

A technology of maleic acid resin and new material, applied in the field of tires, can solve problems such as affecting the dynamic balance of wheels, increasing noise, hidden dangers of driving safety, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

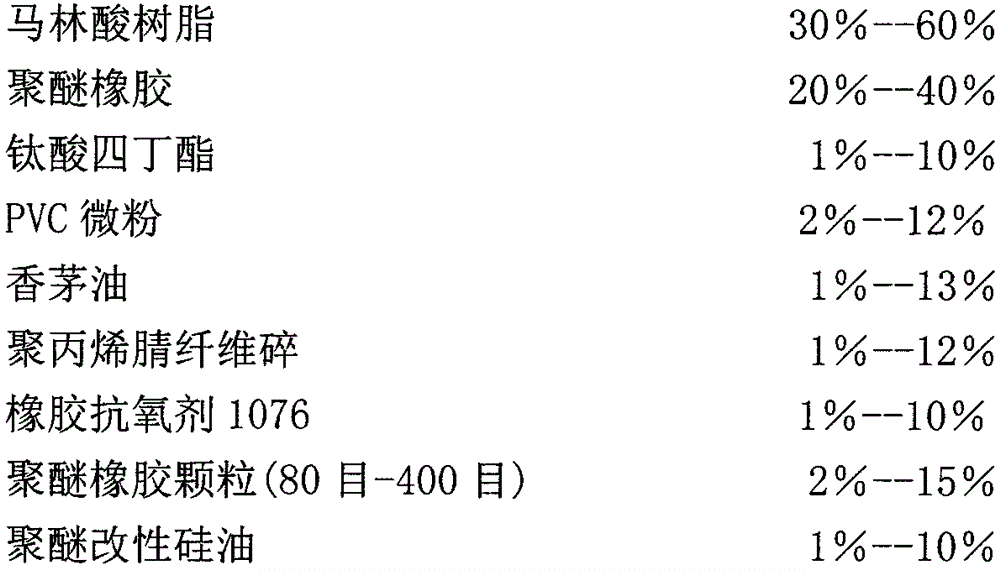

[0010] The composition and weight ratio of the new tire sealing compound material containing maleic acid resin are as follows:

[0011]

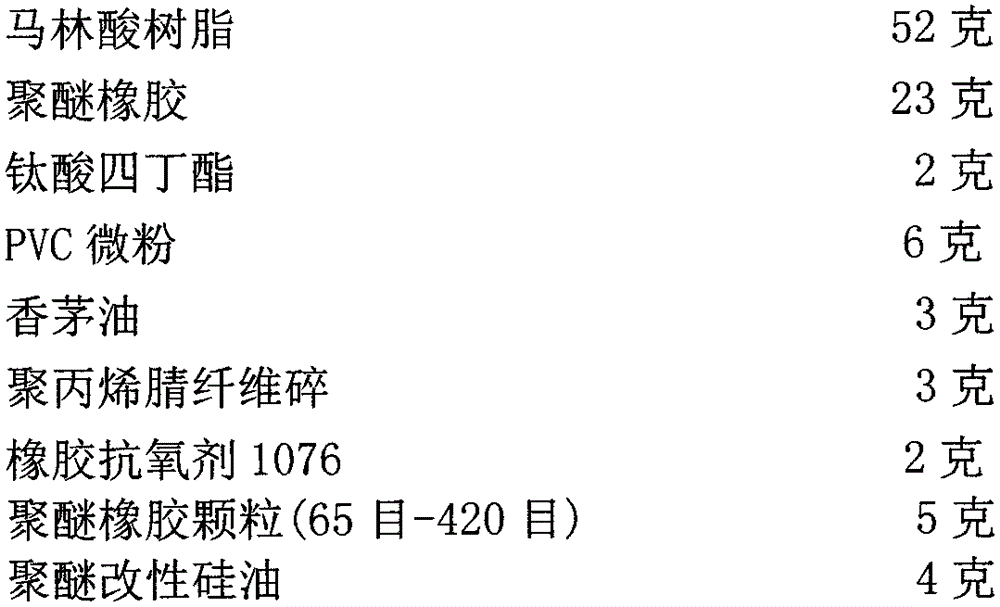

[0012] The tire sealing compound new material containing maleic acid resin in the present invention, its preparation method is: put 52 grams of maleic acid resin, 23 grams of polyether rubber, 2 grams of tetrabutyl titanate, 3 grams of citronella oil into In an electrically heated stirring tank, heat to 159°C and stir for 12 minutes after melting, then add 4 grams of polyether modified silicone oil, 2 grams of rubber antioxidant 1076 and continue stirring for 16 minutes, then add 6 grams of PVC micropowder, 3 gram of polyacrylonitrile fiber fragments, 5 gram of polyether rubber particles (65 orders-420 orders) continue to stir for 18 minutes, complete after stirring evenly, obtain the yellow-brown sticky thing with speckle to be the finished product of the present invention, it is taken from stirring tank Pour out and finish in jars.

Embodiment 2

[0014] The composition and weight ratio of the new tire sealing compound material containing maleic acid resin are as follows:

[0015]

[0016] The new tire sealing composite material containing maleic acid resin is prepared in the same way as that described in Example 1 except that the weight ratio of its components is different.

Embodiment 3

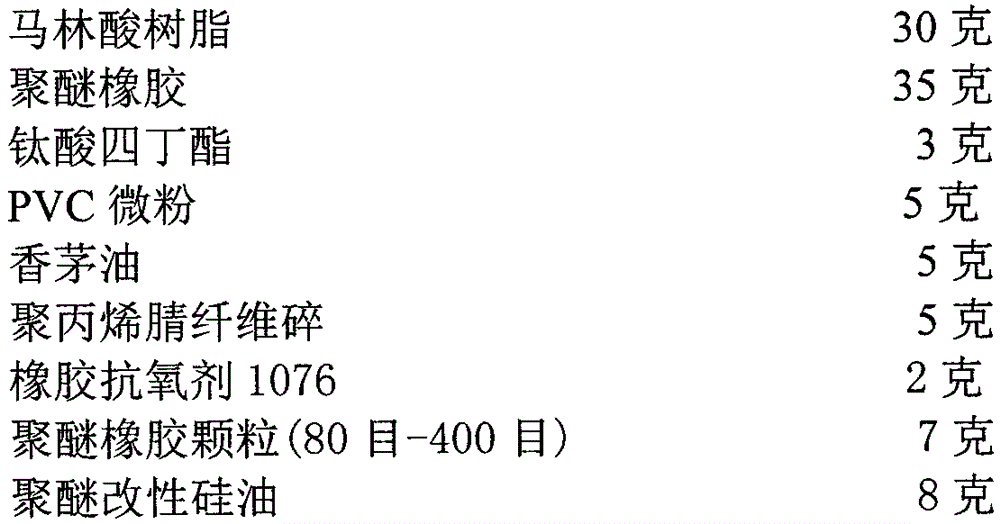

[0018] The composition and weight ratio of the new tire sealing compound material containing maleic acid resin are as follows:

[0019]

[0020] The new tire sealing composite material containing maleic acid resin is prepared in the same way as that described in Example 1 except that the weight ratio of its components is different.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com