Run-flat tire system in which the support ring is placed on the inside of the tread

A run-flat and support ring technology, applied in tire parts, vehicle parts, transportation and packaging, etc., can solve the problems of high cost, difficult promotion, high price, etc., achieve high safety, avoid vehicle overturning, and generate heat little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

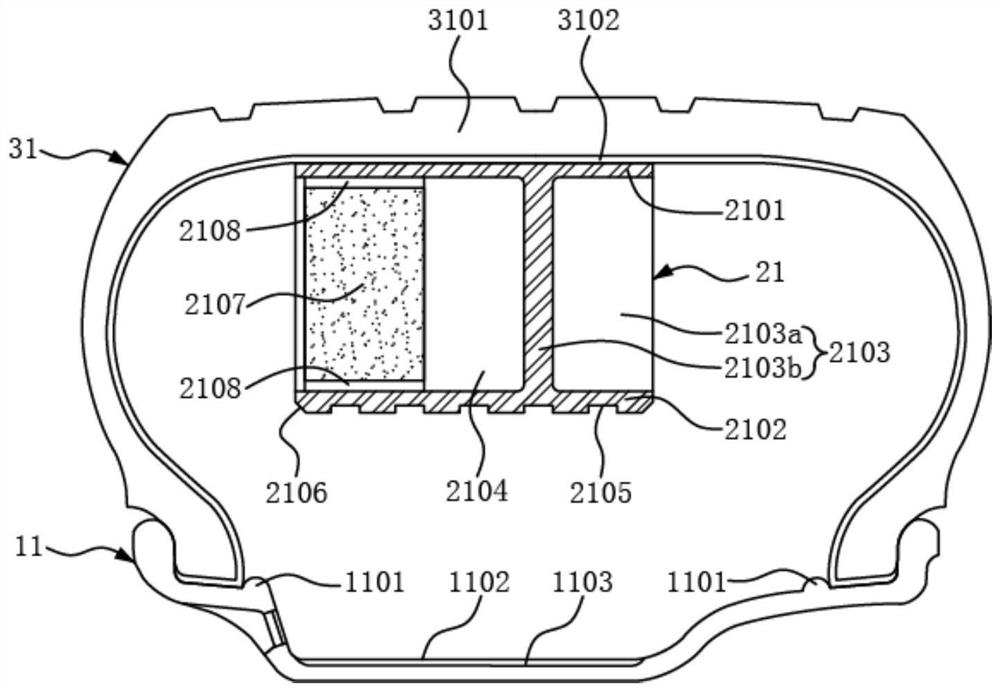

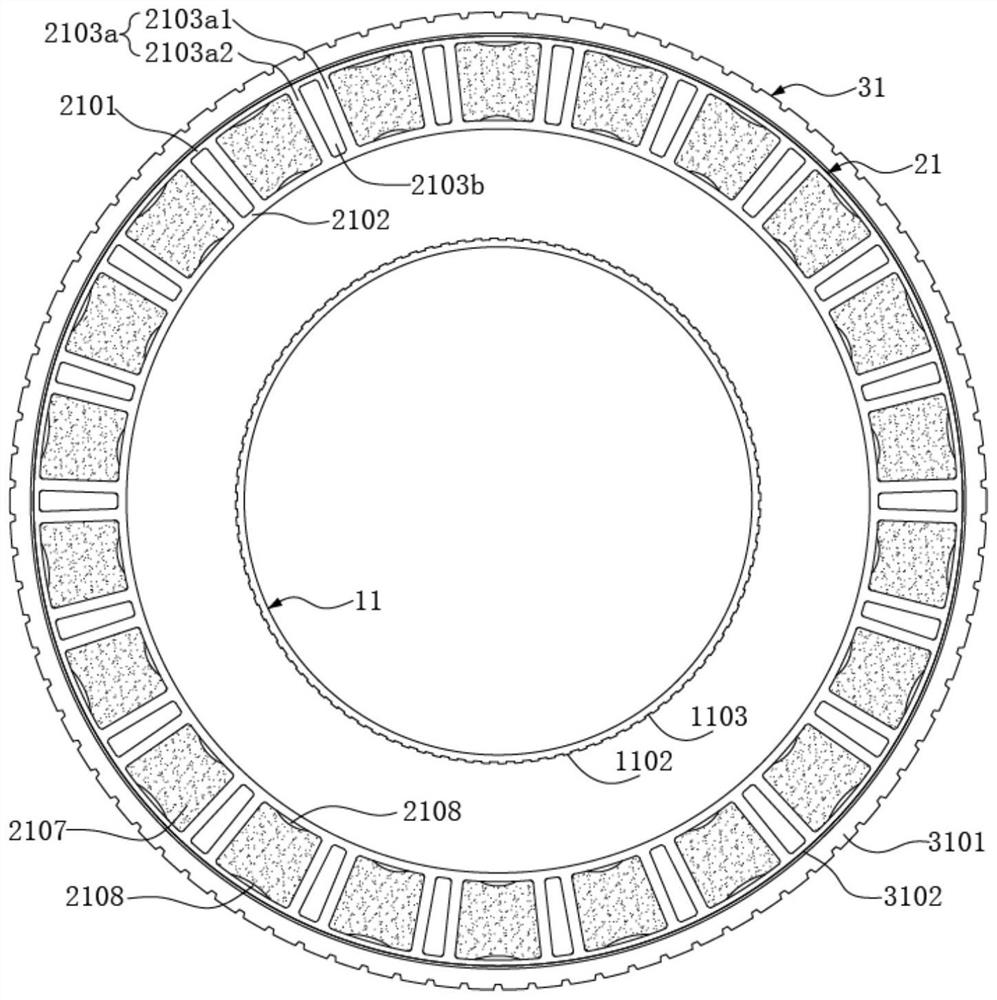

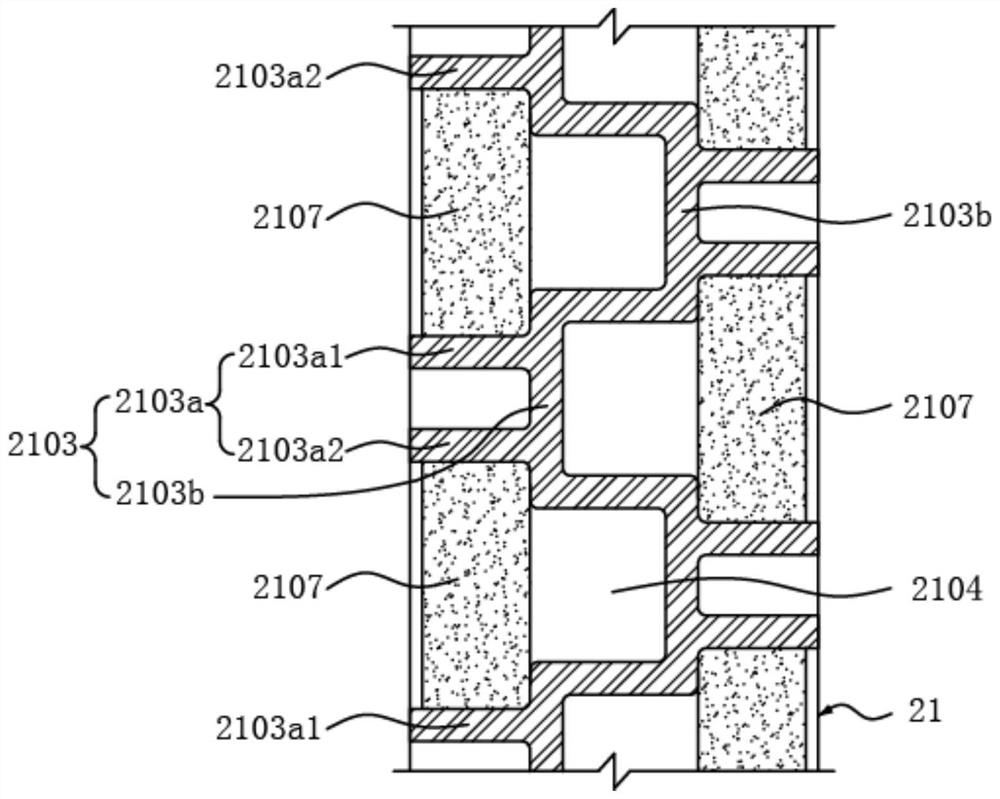

[0070] Such as figure 1 , figure 2 , image 3 As shown, a run-flat tire system in which the support ring is arranged on the inner side of the tread includes a rim 11 , a support ring 21 , and a tire 31 that cooperate with each other. The rim 11 is an integrated deep-groove rim suitable for the tire 31. The special feature is that the bead seat of the rim 11 is provided with a convex peak 1101 at the end close to the deep groove to prevent the bead of the tire 31 from loosening inward, and the rim The deep groove of 11 is set to not only facilitate tire 31 dismounting but also has the flat-bottomed deep groove 1102 that cooperates support ring 21 to support wheel under deflated state concurrently; The groove bottom is configured as a flat bottom in the axial direction, and the axial width of the flat bottom is not less than 1 / 3 of the axial width of the rim 11 and not greater than 2 / 3 of the axial width of the rim 11; An axial groove 1103 is arranged in the axial direction...

Embodiment 2

[0072] Such as Figure 4 , Figure 5 , Figure 6As shown, a run-flat tire system in which the support ring is arranged on the inner side of the tread includes a rim 11 , a support ring 22 and a tire 32 that cooperate with each other. For details of the rim 11, see Embodiment 1. The support ring 22 is basically the same as the support ring 21 in Embodiment 1, the difference is: (1) the axial width of the support ring 22 is equal to the axial width of the groove bottom of the flat-bottomed deep groove 1102 of the rim 11; (2) the support ring The circumferential outer ring 2201 of the tire 22 is arranged in two layers, the outer layer part is called the outer layer 2201a, and the inner layer part is called the inner layer 2201b, wherein the outer peripheral surface of the outer layer 2201a fits the inner lining of the tread 3201 of the tire 32 3202, the thickness of the outer layer 2201a is not less than the thickness of the inner layer 2201b. In this embodiment, the thickness...

Embodiment 3

[0074] Such as Figure 7 , Figure 8 , Figure 9 As shown, a run-flat tire system in which the support ring is arranged on the inner side of the tread includes a rim 11 , a support ring 23 , and a tire 33 that cooperate with each other. For details of the rim 11, see Embodiment 1. The support ring 23 is basically the same as the support ring 21 in Embodiment 1, the difference is: (1) the circumferential outer ring 2301 of the support ring 23 is set as a first circumferential outer ring 2301a and a second circumferential outer ring 2301b; The outer peripheral surface of the peripheral outer ring 2301a is attached to the inner peripheral surface of the inner lining 3302 of the tread 3301 of the tire 33, and the axial width is equal to 1 / 3-1 / 3 of the axial width of the groove bottom of the flat-bottomed deep groove 1102 of the rim 11. 1 / 2; the second circumferential outer ring 2301b is arranged between the first circumferential outer ring 2301a and the circumferential inner ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com