An organic waste pyrolysis oil and gas purification recovery process and purification recovery device

A technology of organic waste and recovery device, which is applied in the petroleum industry, special forms of dry distillation, coke ovens, etc., can solve the problem of high pressure of cooling and purification separators, and achieve the effect of system safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

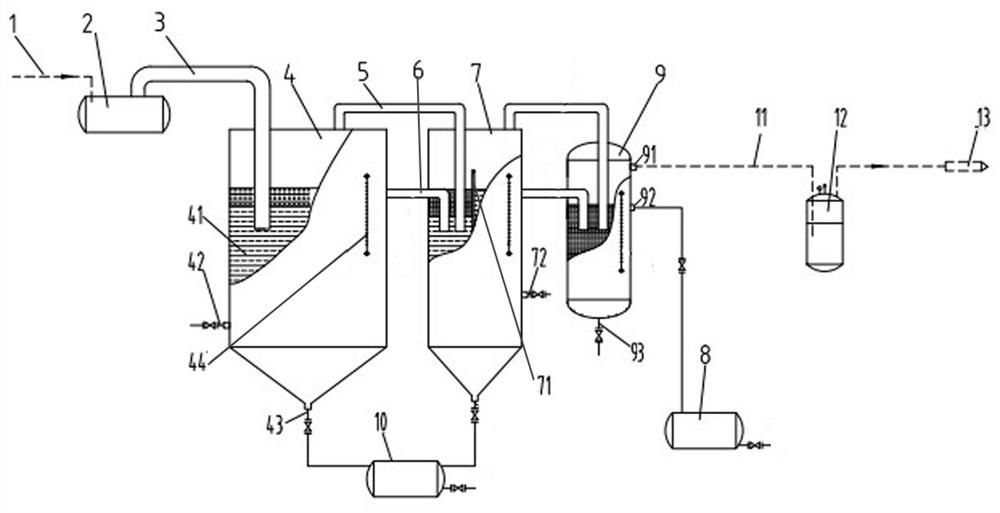

[0021] A process for pyrolysis of organic waste oil and gas purification and recovery. The high-temperature pyrolysis oil gas 1 enters the multi-stage cooling and purification separator through the gas phase guide pipe 3, or the cracked oil gas is first collected into the gas bag 2, and then enters a gas phase guide pipe 3 into a Stage cooling and purification separator 4, the cooling and purification separators of each stage are connected through the gas phase decompression guide pipe 5 and the liquid phase guide pipe 6, after the high temperature cracked oil gas 1 is cooled and absorbed by the water 41 built in the cooling and purification separator of each stage , the separated non-condensable gas 11 is collected from the upper end of the final cooling and purification separator or the non-condensable gas 11 enters the cracking furnace burnback device 13 after being water-sealed in the water-sealed tank 12, and the wax oil is collected from the wax at the lower end of the coo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com