Bearing device for trial assembly of steam turbine vanes and assembly method of steam turbine vanes

A technology of steam turbine blades and bearing devices, which is applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of large disassembly and assembly workload, slow progress, and lack, and achieves low cost, easy production and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

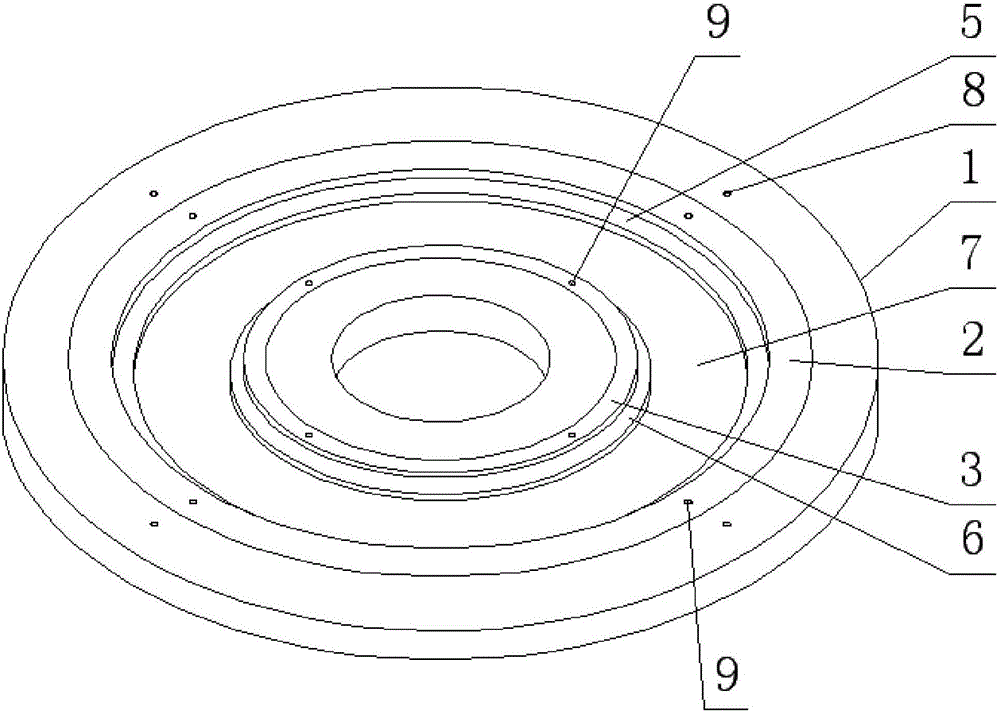

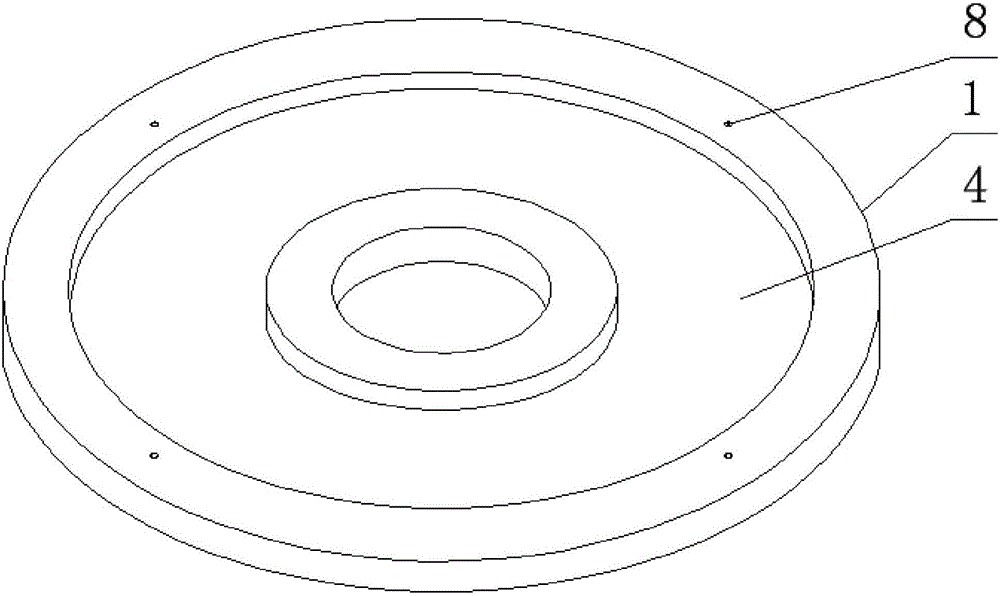

[0024] The bearing device for the trial assembly of steam turbine blades in this embodiment combines figure 1 As shown, its composition includes: a circular ring chassis 1, an outer lining ring 2 and an inner lining ring 3, the circular ring chassis 1 is a circular sheet structure, and one side surface of the circular ring chassis 1 has a groove 4. The outer ring inside the groove 4 places the outer lining ring 2, and the inner ring inside the groove 4 places the inner lining ring 3; wherein,

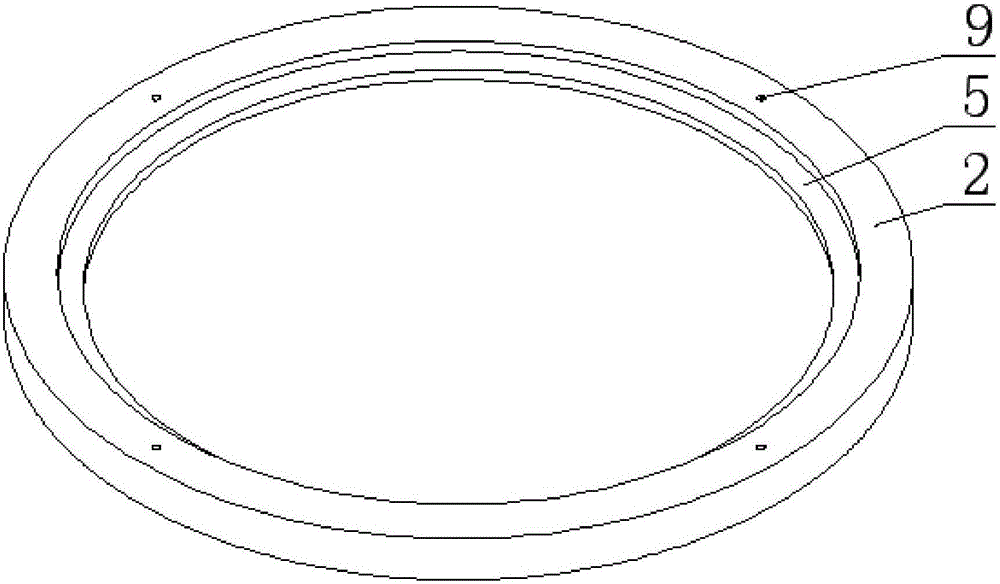

[0025] There is an inner ring shoulder 5 on the inner ring side wall of the outer backing ring 2, the thickness of the inner ring shoulder 5 is smaller than the thickness of the outer backing ring 2, and the outer backing ring 2 and the inner ring shoulder 5 form a stepped structure;

[0026] There is an outer ring shoulder 6 on the outer ring side wall of the inner lining ring 3, the thickness of the outer ring shoulder 6 is smaller than the thickness of the inner lining ring 3, and th...

specific Embodiment approach 2

[0028] The difference from Embodiment 1 is that in the bearing device for trial assembly of steam turbine blades in this embodiment, a group of lifting screw holes 8 are evenly distributed in the circumferential direction on the side of the annular chassis 1 with the groove 4 .

specific Embodiment approach 3

[0029] The difference from Embodiment 1 or Embodiment 2 is that, in the bearing device for trial assembly of steam turbine blades in this embodiment, a group of ring holes 9 are evenly distributed on the surface of the outer lining ring 2 in the circumferential direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com