Carbon deposit generation test platform for direct-injection oil injector in automobile engine cylinder

An automobile engine and in-cylinder direct injection technology, which is applied in the direction of engine components, engine testing, machine/engine, etc., can solve the problems of complex influencing factors, high cost, unclear results, etc., and achieve high interpretation reliability and power Low consumption and manpower consumption, corresponding clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

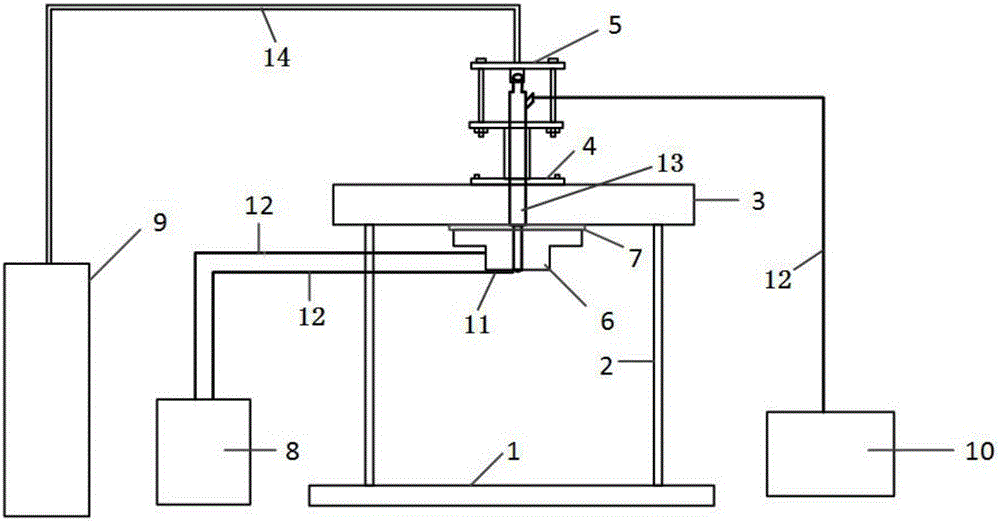

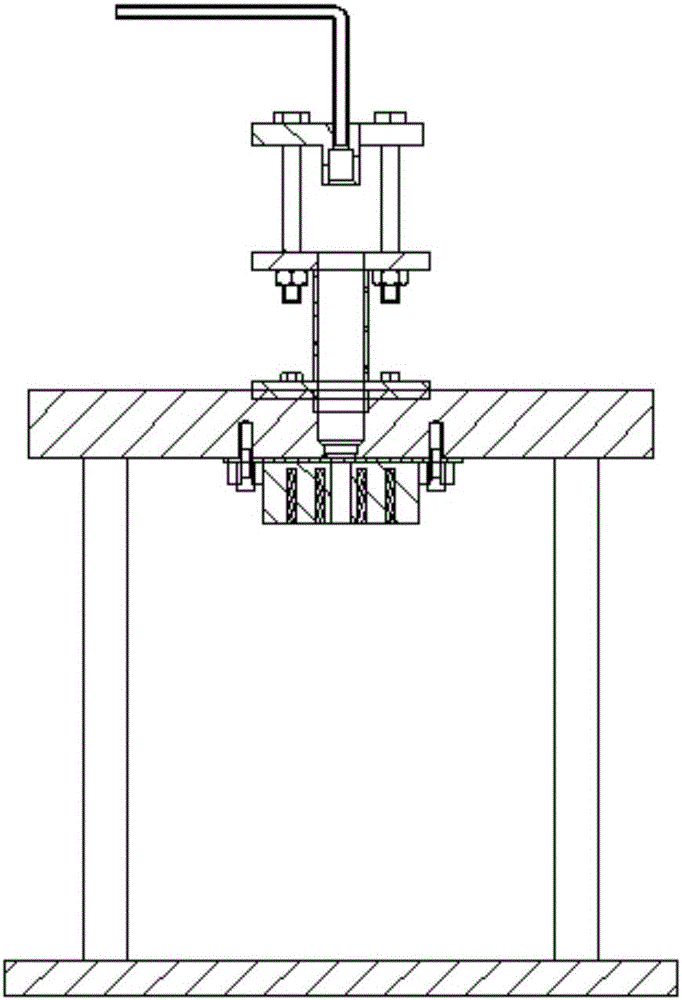

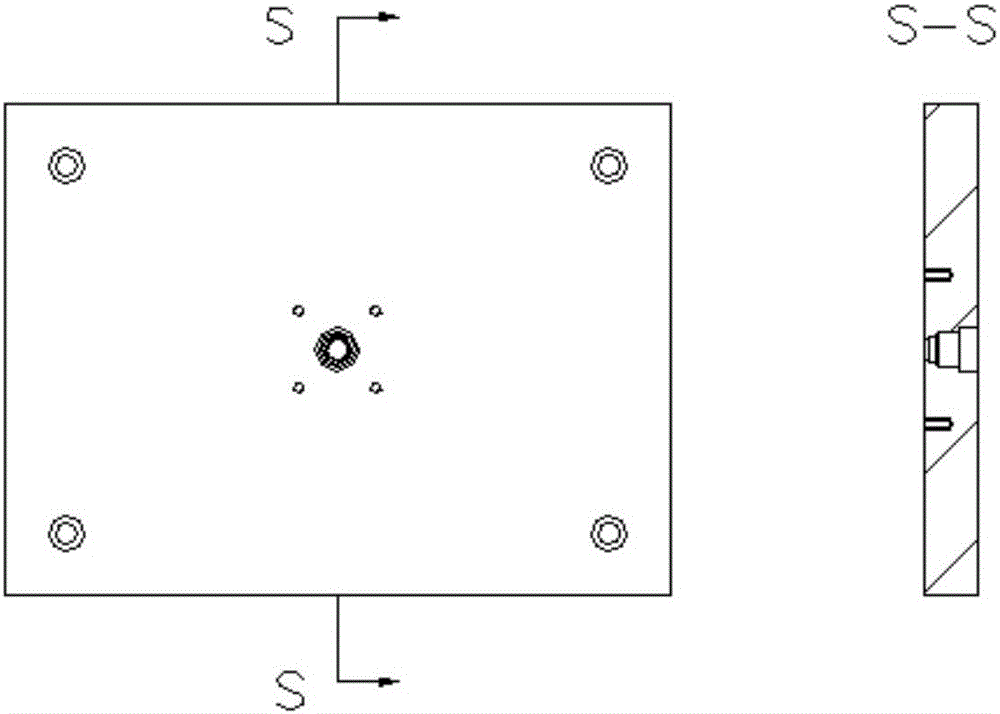

[0026] Such as Figure 1 to Figure 8 As shown, the present invention includes a base 1, a support column 2, a fuel injector mounting plate 3, a fuel injector fastening connector 4, a fuel inlet mounting seat 5, a nozzle heating part 6, a heat insulation layer 7, a temperature control part 8, Fuel supply system 9, fuel injection control component 10, patch thermocouple 11, wiring harness 12, fuel injector 13, oil pipe 14, four supporting columns 2 are fixed on the base 1 by screw connections, and the fuel injector mounting plate 3 is used The screws are fixed on the support column 2, the fuel injector 13 is arranged on the fuel injector mounting plate 3, the fuel injector fastener 4 is fixed above the fuel injector mounting plate 3 with four screws, and the upper end of the fuel injector 13 Arranged in the fuel inlet installation seat 5, the fuel inlet installation seat 5 is connected with the fuel injector fastener 4 with four bolts, the nozzle heating part 6 is fixed under th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com