An ultra-low temperature pump shaft end mechanical seal device

A mechanical sealing device, ultra-low temperature technology, applied in mechanical equipment, components of pumping devices for elastic fluids, pumps, etc. The effect of good sealing performance and difficult production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

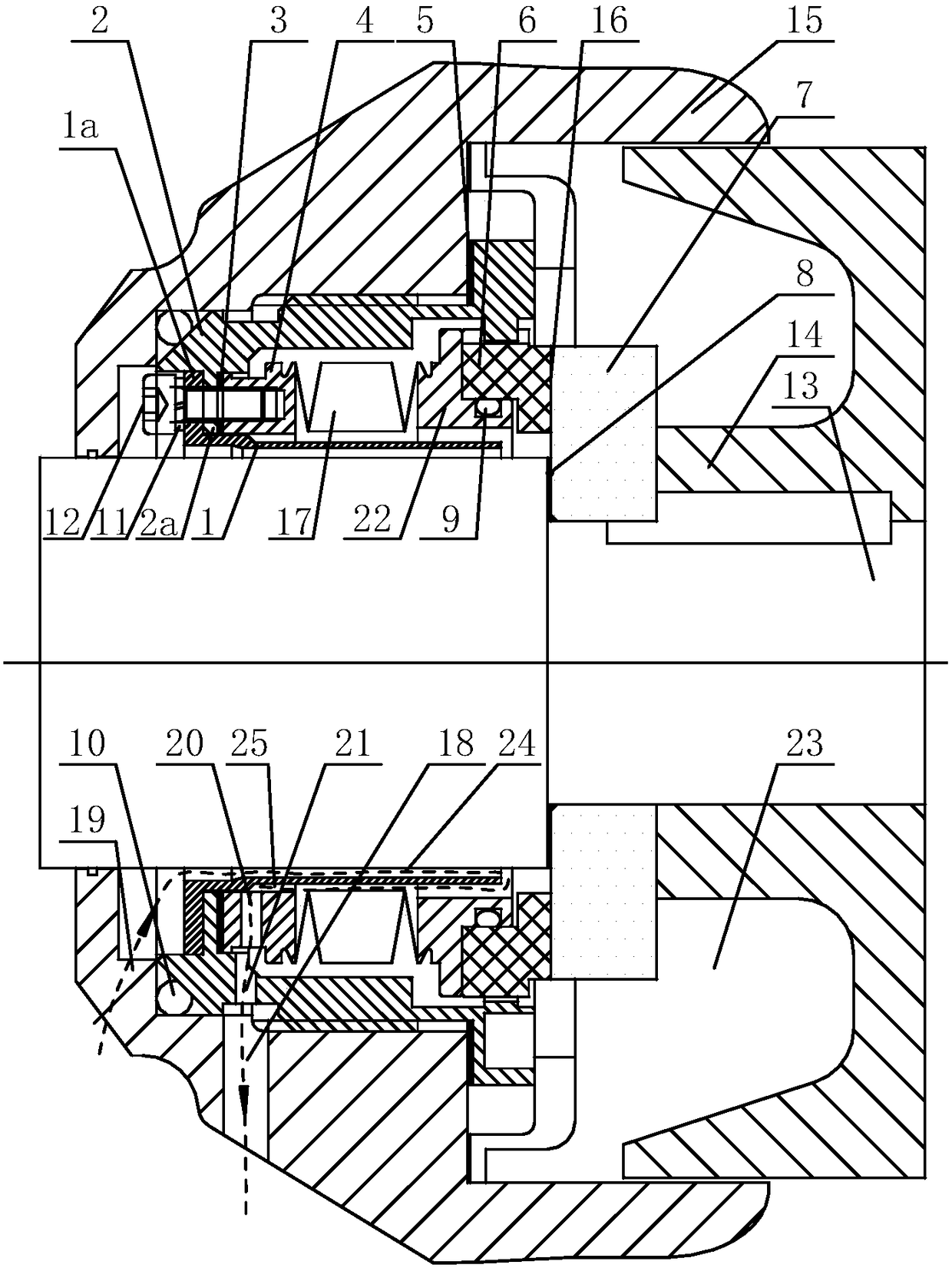

[0030] Below in conjunction with accompanying drawing, technical solution of the present invention is described:

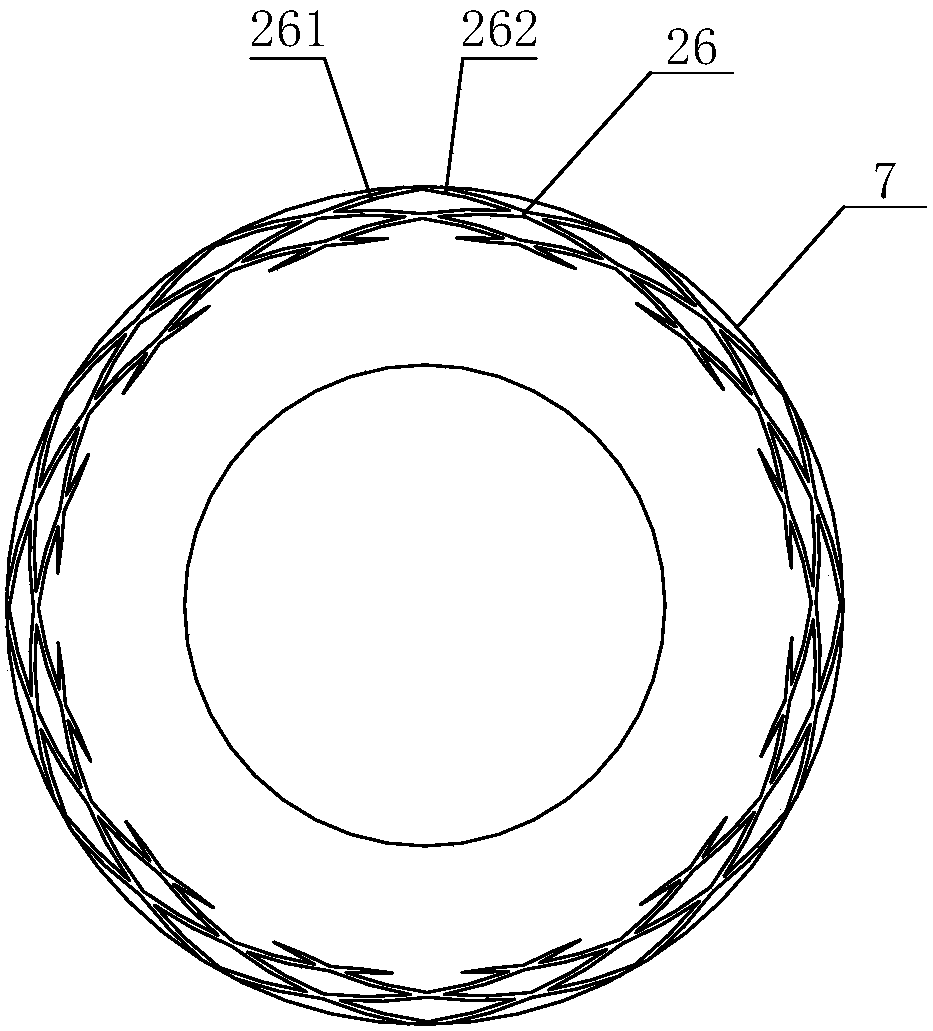

[0031] The present invention includes rotating parts and stationary parts located in the pump casing. The rotating parts include the pump main shaft 13 that drives the impeller 14 in the pump casing 15 to rotate and the moving ring 7 sleeved and fixed on the pump main shaft 13. The stationary The components include a sheath 1 that is sleeved on the pump main shaft 13 and a static ring 6 that fits with the end surface of the moving ring 7 to form a sealing surface 16. A gap is set between the sheath 1 and the static ring 6. The elastic component on the sheath 1, the static ring 6 is attached to the moving ring 7 by the elastic force of the elastic component, and the gap between the sheath 1 and the pump main shaft 13 constitutes the first purge channel 24 , the gap between the sheath 1 and the elastic component constitutes a second purge passage 25, the first purge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com