A non-return joint for chemical discharge

A chemical, non-return technology, applied in the direction of pipes/pipe joints/fittings, connections with fluid cut-off devices, parts in contact between valve elements and valve seats, etc., can solve the problem of damage to corrosion-resistant elastic materials, contamination of chemical Products, unsuitable for high-purity electronic chemicals, etc., to simplify the structure and reduce the chance of contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

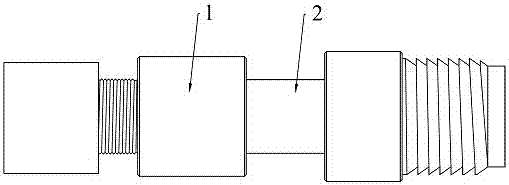

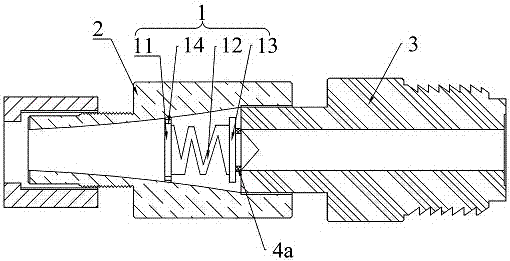

[0028] Such as figure 1 with 2 As shown, the non-return joint for chemical discharge of embodiment 1 includes a polymer check valve core 1 and a first joint 2 and a second joint 3 with a central through hole, and the discharge end of the second joint 3 It is sleeved in the feed end of the first joint 2 and is connected in a sealed manner. The discharge port diameter of the first joint 2 is smaller than that of the feed port. The inner surface of the first joint 2 and the discharge end surface of the second joint 3 form a cavity A check valve core 1 is provided with a middle clearance fit. The check valve core 1 includes a first baffle 11, a polymer compression spring 12, and a second baffle 13, which are connected in sequence, and the first baffle 11 exits toward the first joint 2. A discharge hole 14 is provided between the material end and the inner surface of the first joint 2, the second baffle 13 faces the discharge end of the second joint 3, and the second baffle 13 is san...

Embodiment 2

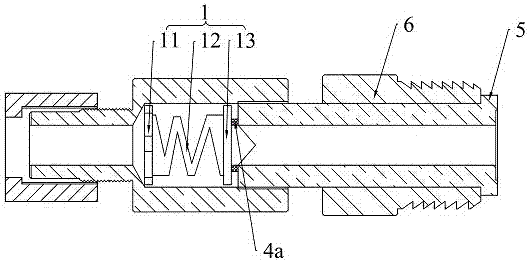

[0037] Such as image 3 As shown, the difference between embodiment 2 and embodiment 1 is that the feed end of the second joint 3 is provided with a flange 5 protruding to the outer periphery, and the outer periphery of the second joint 3 is provided with a movable joint 6 in a clearance fit, and the movable joint 6 is located on the convex Between the rim 5 and the first joint 3, the movable joint 6 is used to connect with a chemical discharge pipe or a packaging barrel.

[0038] A guide block 7 is provided on the surface of the second baffle 13, the first sealing ring 4a is sleeved on the outer circumference of the guide block 7, and the protruding end of the guide block 7 is matched with the discharge port of the second joint.

[0039] The top surface or side surface of the first baffle 11 is provided with a lug 9, and the discharge hole is enclosed by the lug 9, the first baffle 11 and the inner surface of the first joint 2.

[0040] The central through hole of the first joint 2 ...

Embodiment 3

[0043] Such as Figure 4 As shown, the difference between Embodiment 3 and Embodiment 2 is that a convex ring 10 is provided on the outer surface of the second joint 3, and a second sealing ring 4b is provided on the annular surface of the convex ring 10 facing the feeding end surface of the first joint 2. The second sealing ring 4b is sandwiched between the convex ring 10 and the feeding end surface of the first joint 2.

[0044] The ratio of the wire diameter of the compression spring to the inner diameter and pitch of the compression spring is 1:7:2, and the model of the polymer material made of polyvinylidene fluoride is Kynar PVDF 100HD.

[0045] When the ratio of the wire diameter of the compression spring to the inner diameter of the compression spring is less than 1:8 and the pitch is less than 1:3, the deformation force of the compression spring is small, the spring flexibility is relatively large, and the rigidity is insufficient. When the ratio of the wire diameter of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com