Non-flexible compensator for wind box branch pipe of sintering machine

A sintering machine, non-flexible technology, applied to expansion compensation devices, pipe components, mechanical equipment and other directions for pipelines, can solve the requirements of large thermal expansion, aging of fluorine rubber, and the inability to meet the compensation of flexible compensators, etc. Achieve long service life and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

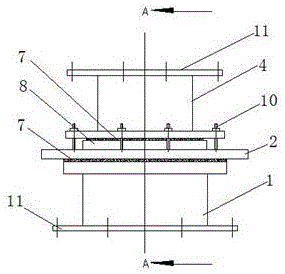

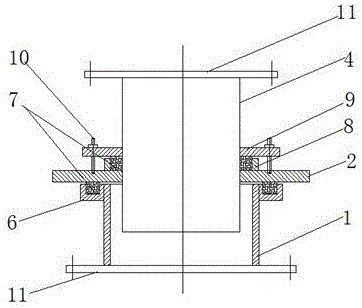

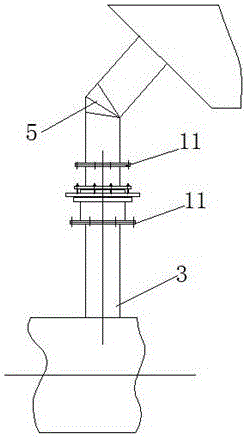

[0017] Figure 1 ~ Figure 3 It is shown that a non-flexible compensator for branch pipes of a sintering machine bellows in the present invention includes a horizontal sliding device and a vertical telescopic device. The horizontal sliding device includes a base 1 and a slip ring 2. The base 1 is a metal circular pipe, and its lower end is connected to the The straight pipe 3 of the branch pipe of the bellows of the sintering machine is connected by the connecting flange 11, and the slip ring 2 is an annular metal plate, which is covered on the upper end surface of the base 1; the inner diameter of the slip ring 2 is smaller than the inner diameter of the base 1, and the outer diameter is larger than The outer diameter of the base 1; the upper end of the base 1 is provided with an upward annular groove 6 along the circumferential direction of the base 2, the upper end surface of the annular groove 6 coincides with the upper end surface of the base 1, and the annular groove 6 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com