Profile detection device used for automobile parts

A technology for auto parts and surface detection, applied in the direction of measuring devices, mechanical devices, mechanical measuring devices, etc., can solve the problems of increasing the difficulty of detection, time-consuming detection, reading errors, etc., to ensure high-precision detection, convenient radius, The effect of detecting convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

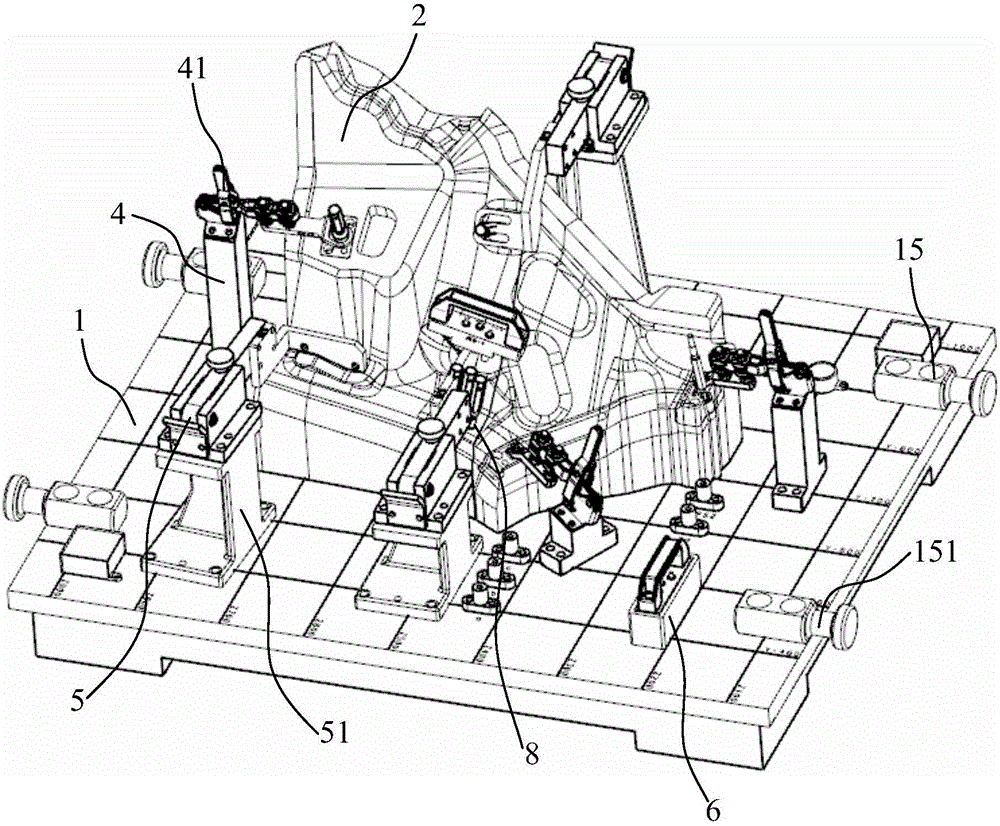

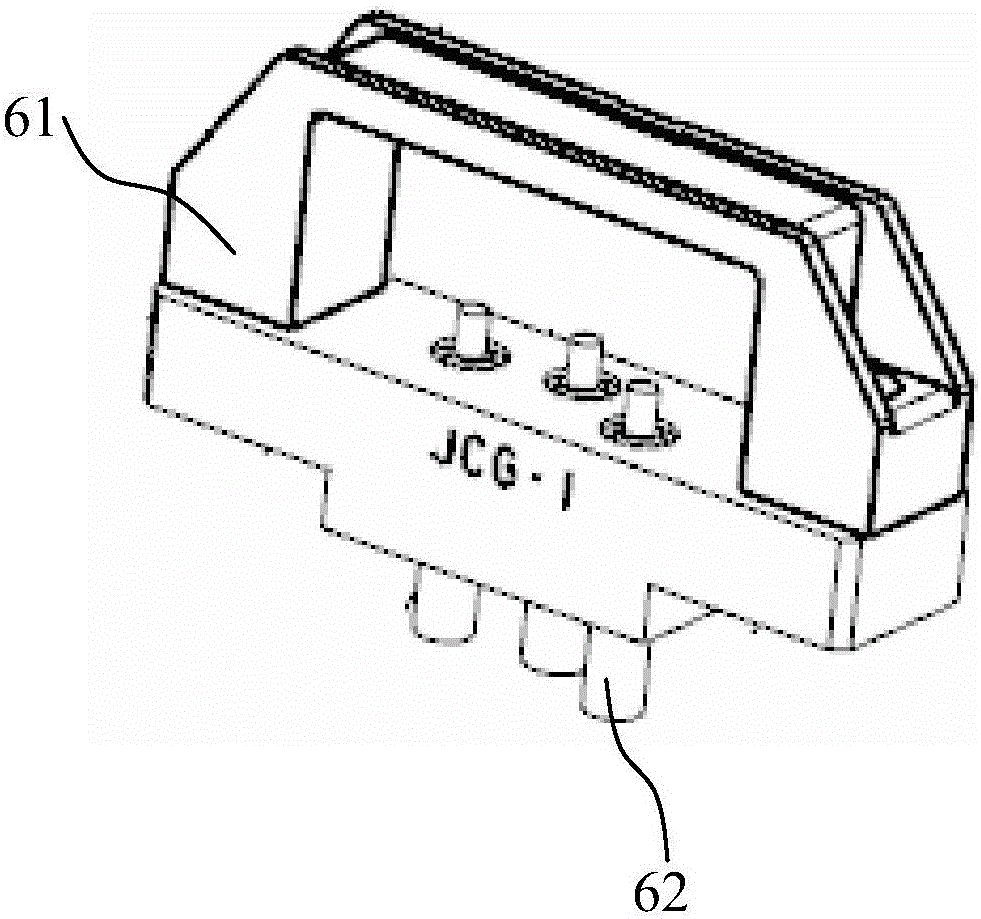

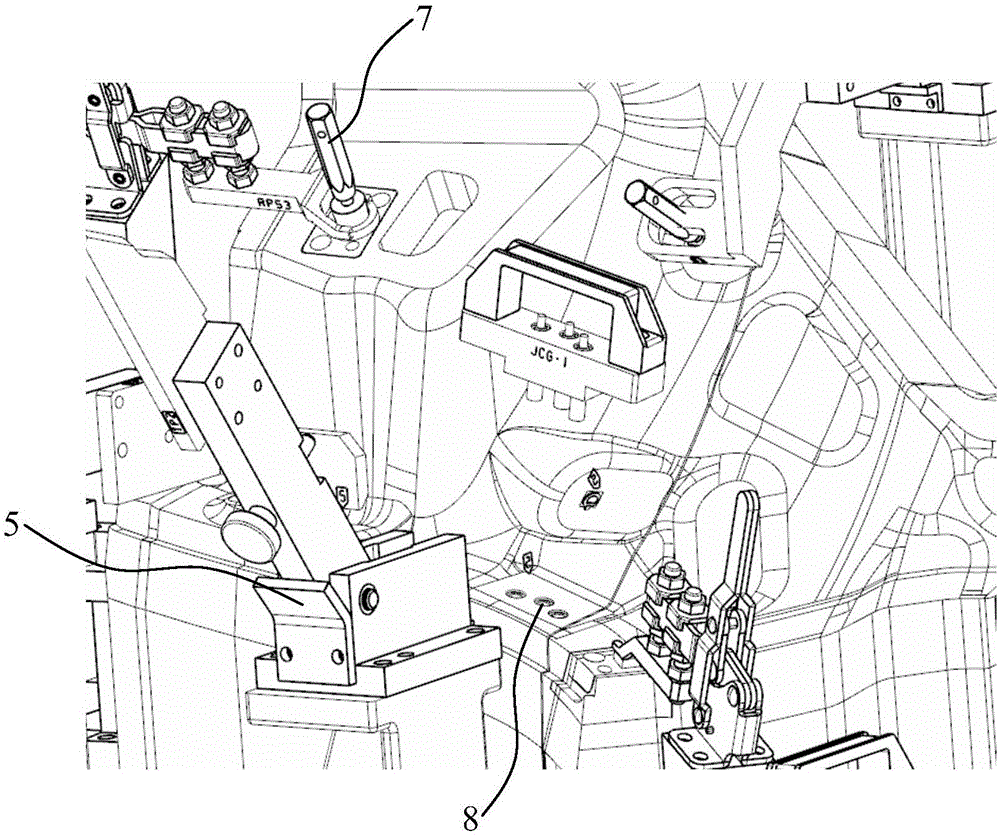

[0027] Embodiment 1: A surface detection device for automobile parts, comprising a coordinate base 1, an analog block seat for placing the parts to be tested, a detection rod 3, at least two clamping mechanisms 4, and at least two gap detection mechanisms 5 The through hole position detection mechanism 6 and the through stop gauge pin 7, the clamping mechanism 4 and the gap detection mechanism 5 are installed on the coordinate base 1, and the clamp 41 located at the upper end of the clamping mechanism 4 is used to clamp and place the analog block For the parts to be tested on the upper surface of the base 2, the through-hole position detection mechanism 6 further includes a handle base 61 and at least two second pins 62 on the bottom surface of the handle base 61;

[0028] The lower part of the through-stop gauge plug 7 is a first latch 71. The middle part of the through-stop gauge plug 7 is provided with a through-regulation part 72 and a regulation-stop part 73 from bottom to to...

Embodiment 2

[0033] Embodiment 2: A surface inspection device for automobile parts, comprising a coordinate base 1, an analog block seat for placing the parts to be inspected 2, a detection rod 3, at least 2 clamping mechanisms 4, and at least 2 gap inspection mechanisms 5 The through hole position detection mechanism 6 and the through stop gauge pin 7, the clamping mechanism 4 and the gap detection mechanism 5 are installed on the coordinate base 1, and the clamp 41 located at the upper end of the clamping mechanism 4 is used to clamp and place the analog block For the parts to be tested on the upper surface of the base 2, the through-hole position detection mechanism 6 further includes a handle base 61 and at least two second pins 62 on the bottom surface of the handle base 61;

[0034] The lower part of the through-stop gauge plug 7 is a first latch 71. The middle part of the through-stop gauge plug 7 is provided with a through-regulation part 72 and a regulation-stop part 73 from bottom to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com