Self-calibration measurement device and method for bridge deformation or displacement parameters

A measuring device and self-calibration technology, applied in the field of mechanical measurement, can solve problems such as increasing system complexity and affecting measurement accuracy, and achieve the effects of convenient application, improved measurement accuracy, and compact and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

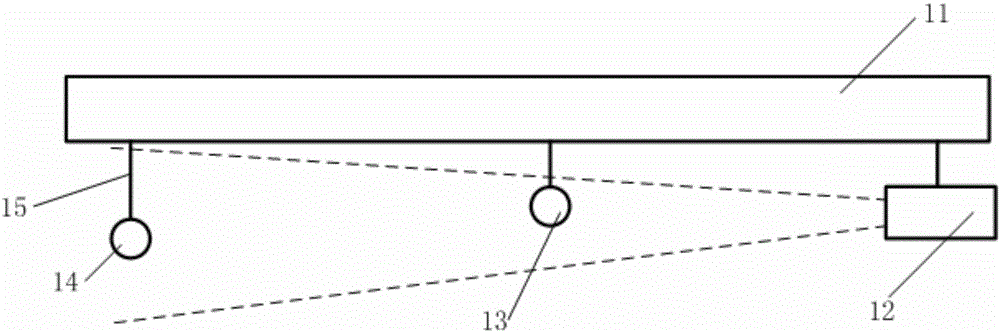

[0035] When the imaging method is used for bridge displacement monitoring, the CCD camera is usually installed in a small displacement area, but when the load vehicle 19 travels to the middle of the bridge, the entire bridge will be bent and deformed, causing the CCD camera to generate an inclination angle relative to the horizontal direction , the inclination angle will be magnified into a large displacement when imaging the measurement target set at a long distance, thus superimposing a system background error on the measured parameter results, which greatly affects the measurement accuracy.

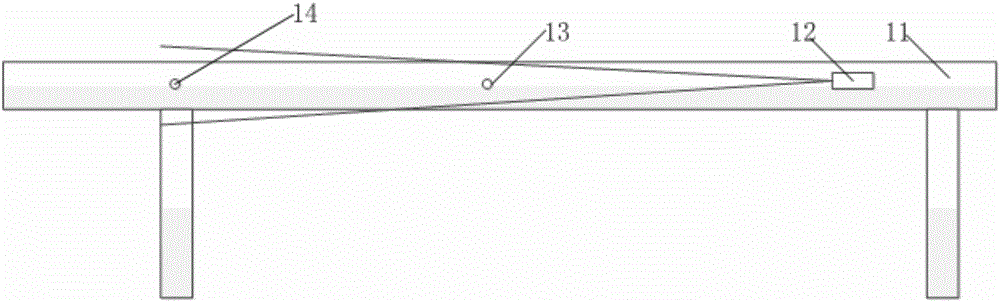

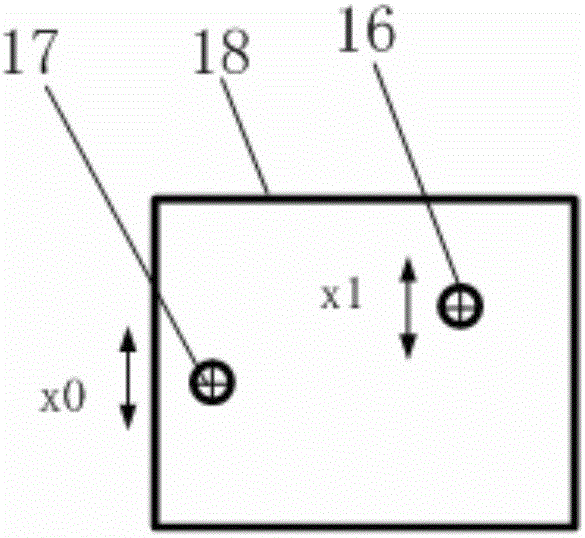

[0036] Such as figure 1 As shown, the present invention is used for the self-calibrating measuring device of bridge deformation or displacement parameters, including imaging system 12, no less than one measurement target 13 installed on the bridge measurement point, and deformation or displacement change installed on the bridge The reference target 14 in the negligible area, the refere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com