Signal picking device for local vibration sensing and monitoring of wall of coke chamber in decoking process, and installation method

A technology of vibration sensing and signal pickup, which is applied in the field of coking tower decoking, can solve problems such as limited temperature resistance, reduced service life of ejector pins and sensors, and inability to accurately pick up local vibration signals of the tower wall, so as to achieve sensitive vibration signals and long-term Apply reliable, easy-to-install effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with specific examples and accompanying drawings.

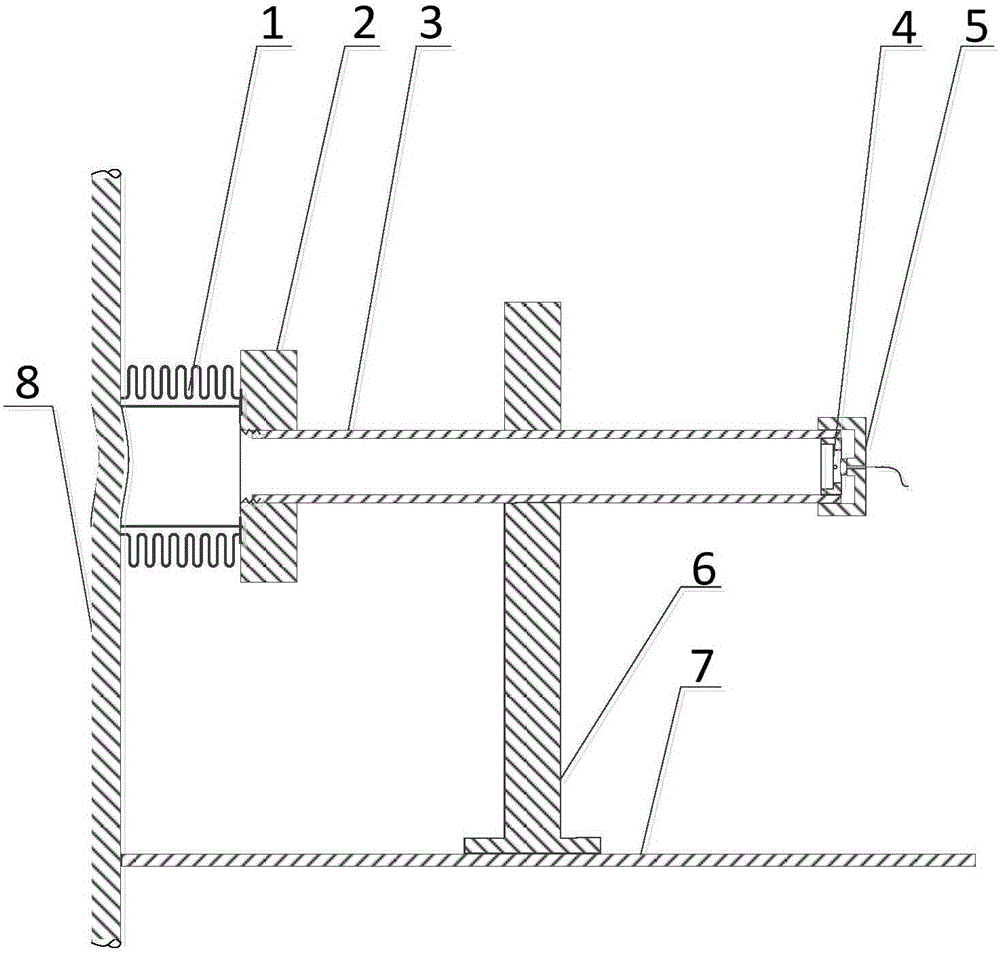

[0016] A signal pick-up device for monitoring the local vibration of the tower wall during the decoking process of the coke tower, such as figure 1 As shown, it includes the sensor installation member 5, and also includes a hollow vibration conduction pipe body, one end of the vibration conduction pipe body is fixedly connected with the coke tower wall 8, and the other end of the vibration conduction pipe body is connected with a vibration sensitive diaphragm and its installation member 4 , while the other end of the vibration conduction pipe body is connected with the sensor mounting member 5; the inside of the vibration conduction pipe body is an air cavity that communicates with the coke tower wall 8 and the vibration sensitive diaphragm and is sealed from the outside world; The vibration conducting pipe body is fixed on the working platform 7 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com