Reciprocating double-station friction-wear tester

A friction and wear test, double-station technology, applied in the direction of testing wear resistance, using mechanical devices, measuring devices, etc., can solve the problems of large inertial force vibration, unable to test multiple pads at the same time, and achieve the expansion speed The effect of simulating range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Preferred embodiments of the present invention are described in detail as follows in conjunction with accompanying drawings:

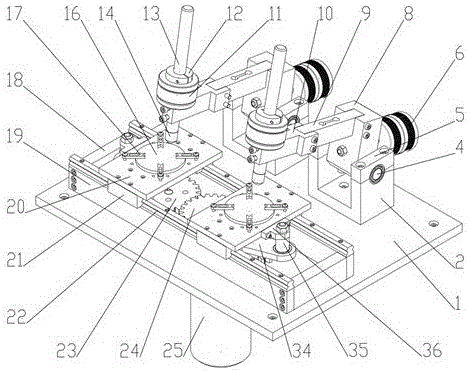

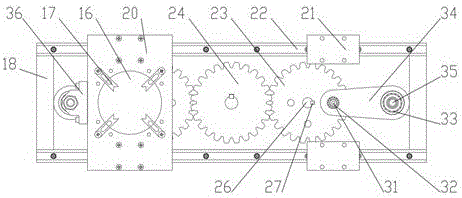

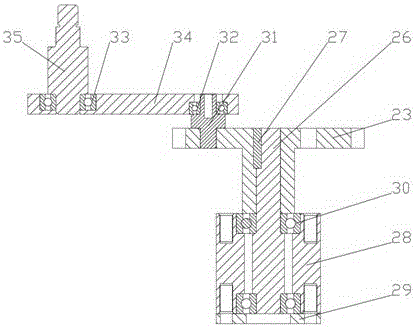

[0022] see figure 1 , a reciprocating double-station friction and wear testing machine, including a machine base 1, a driving system, a loading system and a measurement and control system, the driving system is fixed on the machine base 1, and drives the entire test bench to run; the loading system uses one end Loading, one end is balanced, the middle is supported by shafts and bearings and can swing, and it is installed on the machine base 1. When the floating end is not loaded, the balance weight 6 at the other end is adjusted to realize the swing arm Balance at any position; the measurement and control system is made up of force sensor 9 and eddy current displacement sensor 37, force sensor 9 is formed in the swing arm structure, is used for measuring the friction coefficient of liner material, and eddy current displacement sensor 37 is place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com