A Control Method of Structural Vibration Poles Allocation Based on Non-probabilistic Reliability Optimization

A technique for pole placement and structural vibration, used in adaptive control, general control systems, control/regulation systems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The embodiments of the present invention will be further described in detail below with reference to the accompanying drawings.

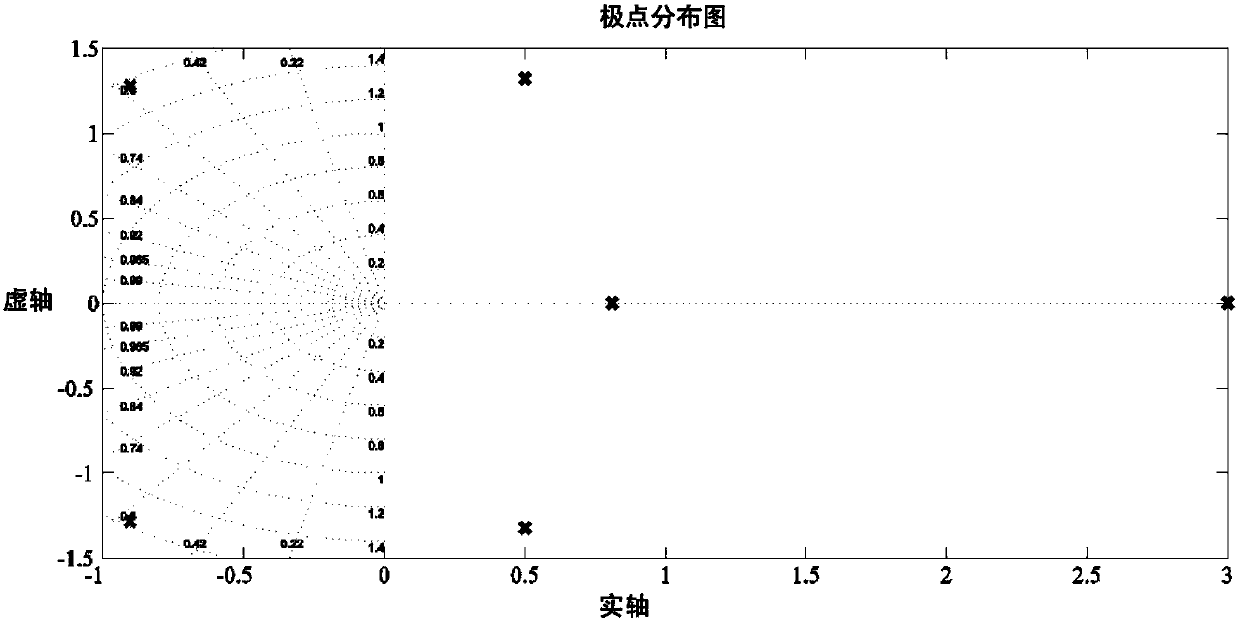

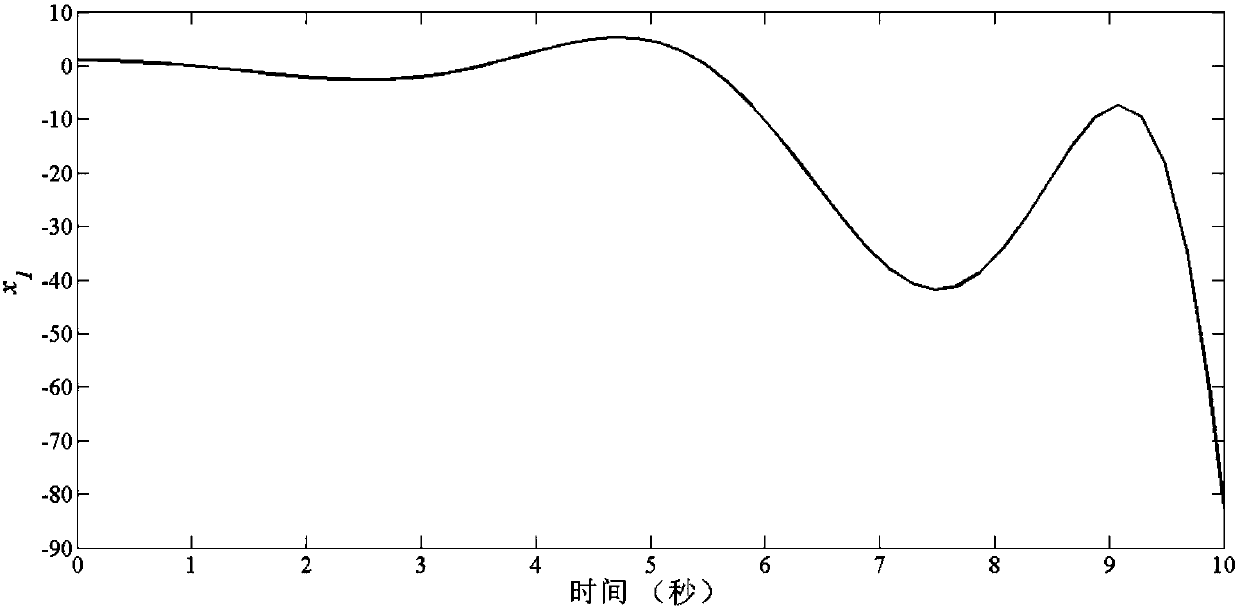

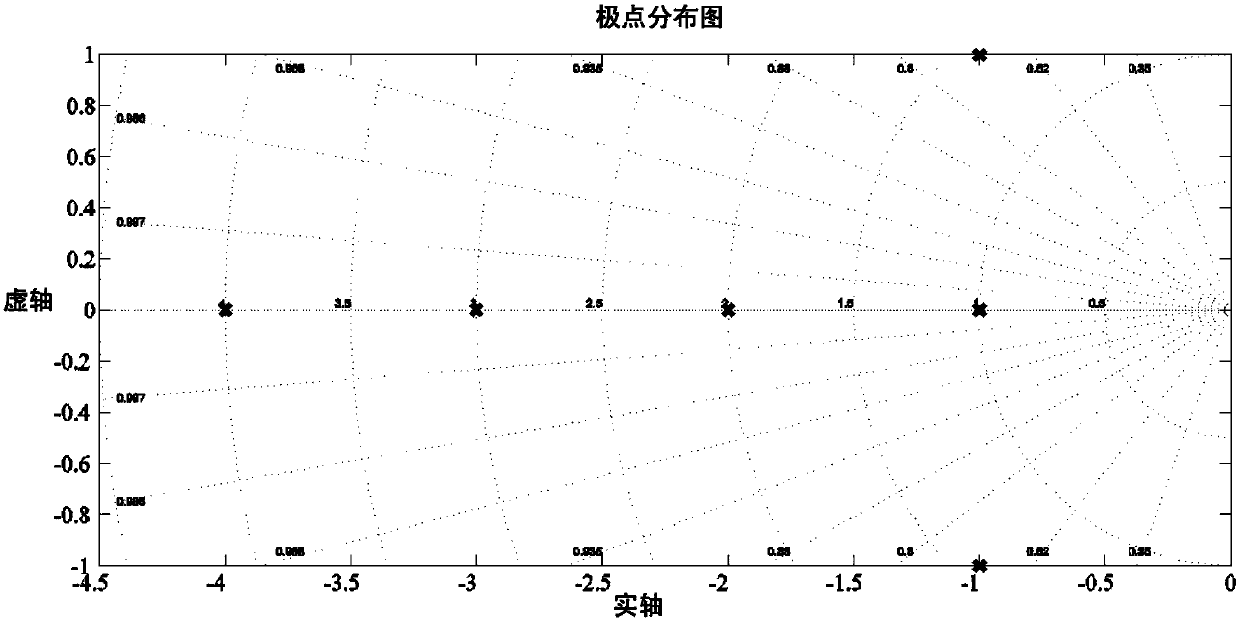

[0038] The technical solution of the present invention: a structural vibration pole configuration control method based on non-probabilistic reliability optimization. First, an active control closed-loop system of structural vibration pole configuration is established. Then, for the established closed-loop output feedback active control system, an interval estimation method for the eigenvalues of the closed-loop output feedback active control system with interval parameters is proposed. On this basis, a non-probabilistic reliability calculation method for closed-loop output feedback active control systems is established. The output feedback controller is optimized based on the interval estimation method and the non-probabilistic reliability calculation method of the eigenvalues of the closed-loop output feedback active control system with int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com