A Reliability Evaluation Method for the Gear Pair of High Pressure Internal Gear Pump

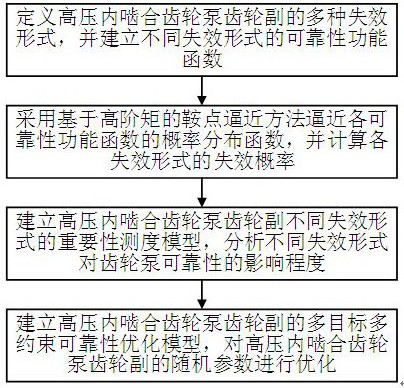

A technology of internal meshing gear pumps and gear pairs, applied to instruments, geometric CAD, probabilistic CAD, etc., can solve the problems of poor reliability, performance degradation, high early failure rate, etc., and achieve overall efficiency improvement, pressure pulsation value and noise reduction, The effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

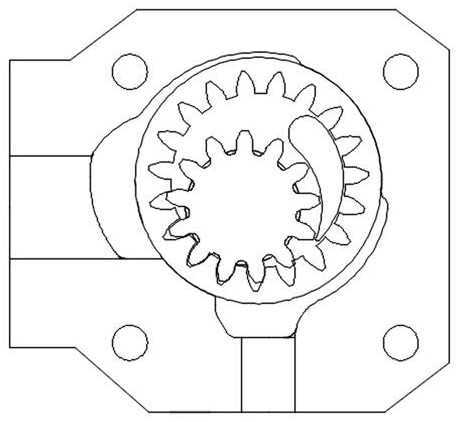

[0073] In order to understand more fully the characteristics and engineering applicability of this invention, the present invention aims at such as figure 2 The gear pair structure of the high-pressure internal gear pump shown is designed for reliability.

[0074] The three failure types of the gear pair are defined as: contact strength failure of the tooth surface of the internal gear pair, bending strength failure of the tooth root of the internal gear, and bending strength failure of the tooth root of the internal gear pair. According to the stress-strength interference theory, the reliability function functions of the three failure types are respectively established, namely

[0075] g 1 (X 1 )=σ' Hlim -σ H

[0076] g 2 (X 2 )=σ' Flim -σ F

[0077] g 3 (X 3 )=σ' Flim -σ F

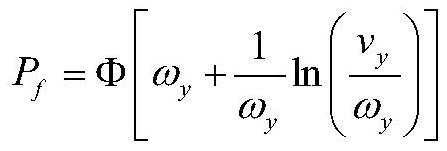

[0078] According to X 1 , X 2 and x 3 The probability information of each random parameter in , respectively calculate the fourth-order moment of each reliability function function, sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com