CAN-bus industrial production line monitoring system and fuzzy control method for yam flour

A technology of CAN bus and CAN controller, which is applied in the field of fuzzy control of yam powder industrial production line, can solve problems such as difficulty in forming a network, narrow and long process flow, and no large number of communication nodes in the horizontal area, so as to reduce failure rate, simple logic structure, and realize The effect of ultra-precision cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

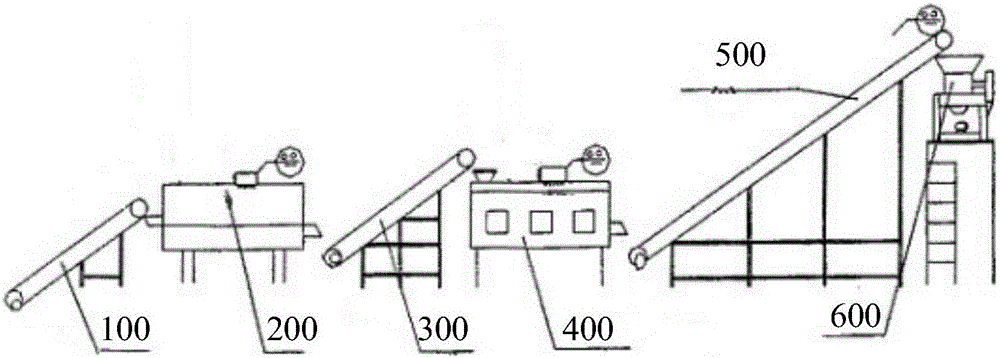

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

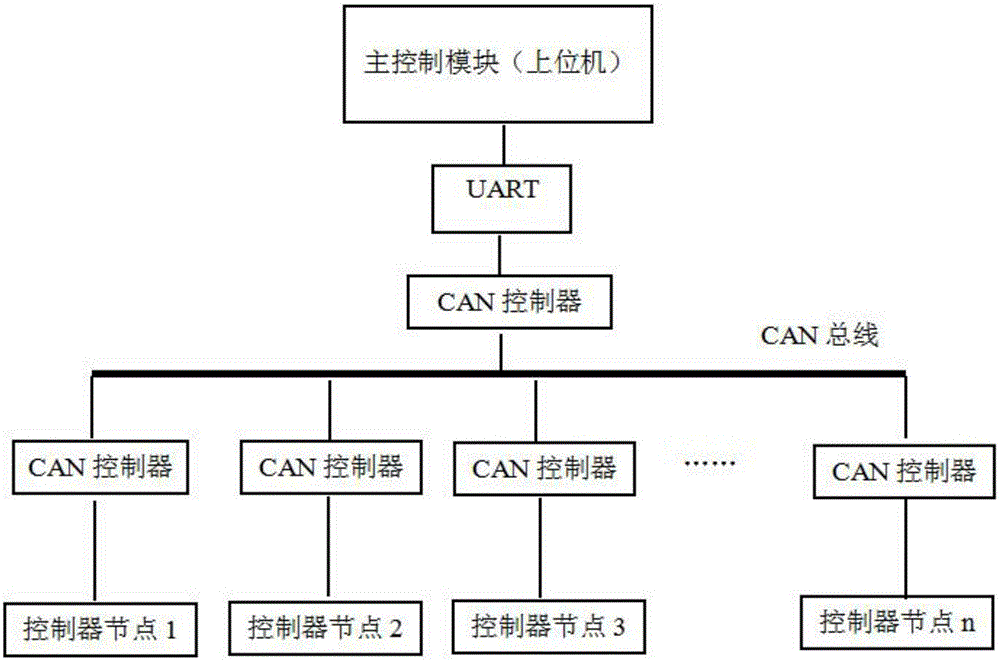

[0038] Such as figure 1 As shown, the present invention provides a CAN bus-based yam powder industrial production line monitoring system provided by the invention, including: a CAN bus communication circuit, a main control module and a controller node.

[0039] Wherein the CAN bus communication circuit includes at least one CAN controller and CAN transceiver, which has functions of receiving and sending and can complete message filtering;

[0040] The main control module, which is connected to the CAN bus communication circuit, can monitor the working state of the system and effectively control the operation of the system;

[0041] A plurality of controller nodes, which are connected to the CAN controller, each node can independently complete corresponding data processing an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com