Method for optimizing weld lines on unequal-thickness tailor-welded panels

An optimization method and tailor-welded blank technology, applied in design optimization/simulation, special data processing applications, instruments, etc., can solve the problems of limited actual effect and no guarantee of weld line drift control accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiment is described below in conjunction with accompanying drawing and specific examples:

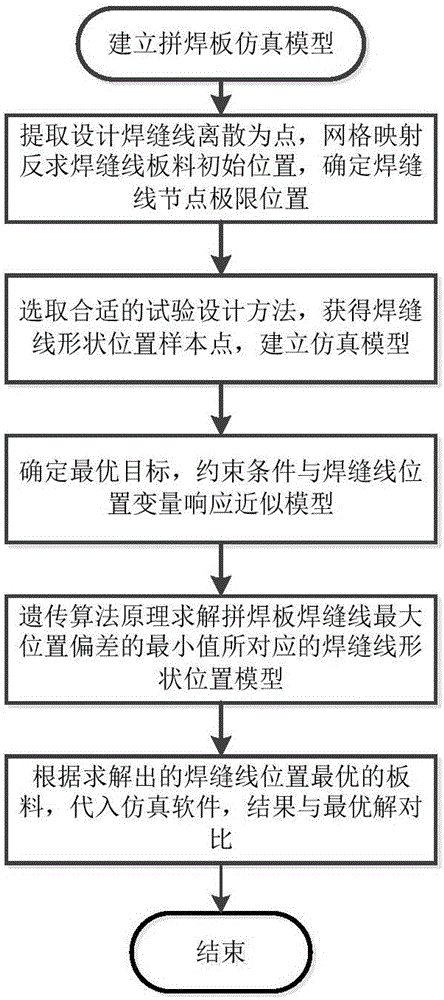

[0027] figure 1 It is a schematic flow diagram of the implementation of the method of the present invention.

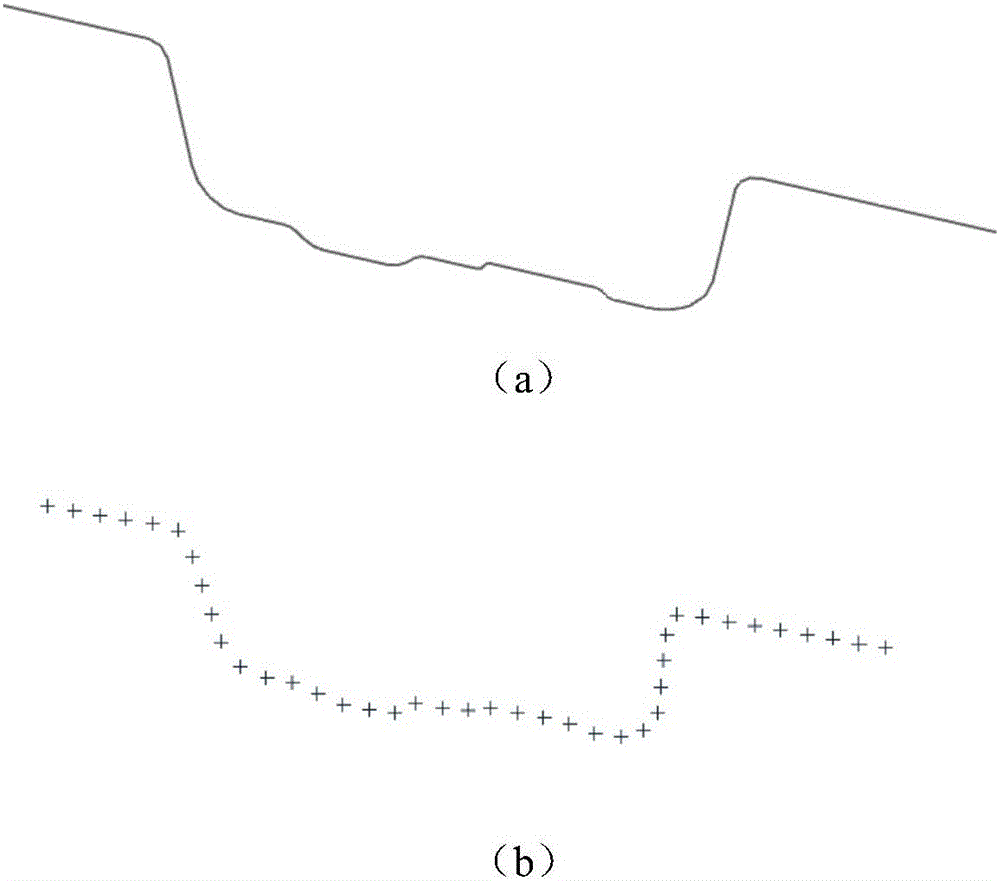

[0028] figure 2 Schematic diagram for extracting product model weld lines. In the product design model of tailor-welded blank parts, the holes and other processes are processed to supplement the overall model of the process supplementary surface part of the binder surface, and the total weld line including the product part is extracted figure 2 (a), figure 2 (b) Take the discrete nodes for the weld line.

[0029] image 3 Schematic diagram of the reverse calculation of the original limit position of the sheet metal weld line for the grid mapping method.

[0030] Figure 4 It is a schematic diagram of the specific determination method for one or more sections of weld lines. According to the initial position of the weld line node calculated inversely, the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com