Method for measuring ultimate heap capacity of building rubbish heaping slope

A measurement method and garbage dump technology, applied in the direction of instruments, geometric CAD, calculation, etc., can solve problems such as material composition, particle size and complex structure, difficult to determine the area, and extremely demanding requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

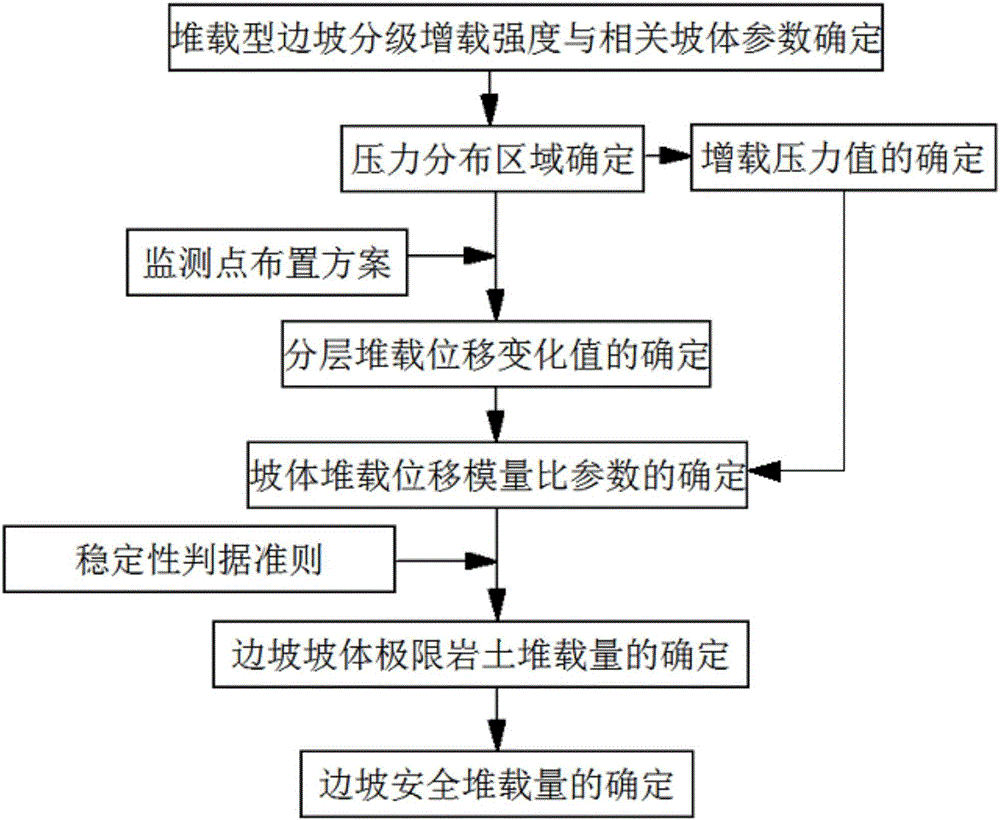

Method used

Image

Examples

Embodiment Construction

[0165] For better illustrating the present invention, the present invention discusses its possibility in detail in conjunction with a certain piled landslide, to prove its practical significance and value.

[0166] Step 1: Determination of load-increasing strength and related slope parameters

[0167] Use total station, level, theodolite and other measuring instruments to determine the slope angle α during the loading process of each layer i and stacking height h i , using the indoor geotechnical test to comprehensively measure the soil weight of each layer of slope body γ i , see Table 2 for specific data.

[0168] Table 2 Parameter table of slope angle and height of each layer of stacked slope

[0169]

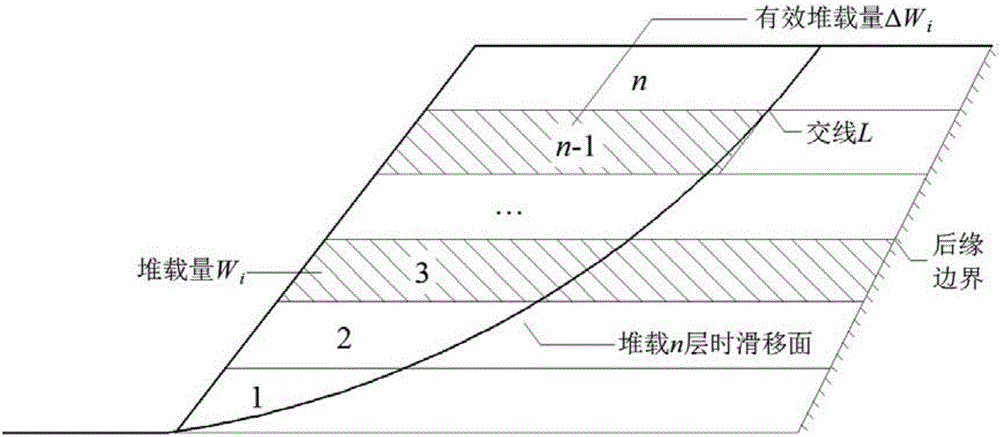

[0170] The second step: Determination of the distribution area and pressure value of the incremental loading pressure of the piled slope;

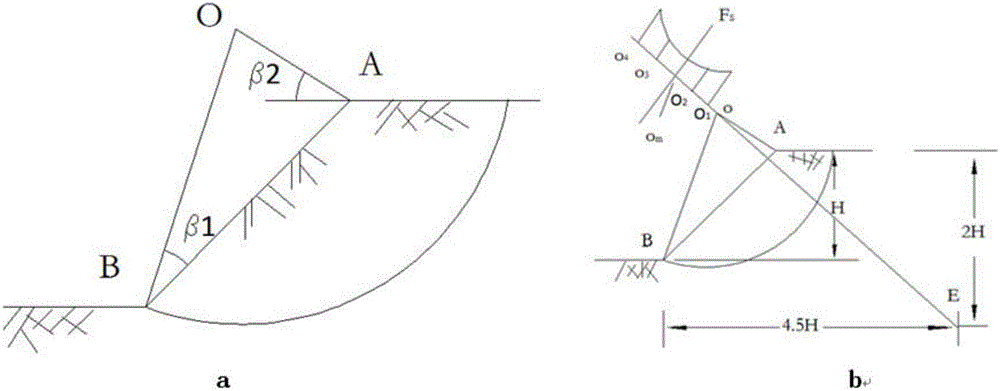

[0171] 1) Determination of the dangerous slip surface area of the slope

[0172] Use the Fellenius method to determine the da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com