A terminal structure of a power semiconductor device

A technology of power semiconductor and terminal structure, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of large occupation area and rising device cost, and achieve the effect of alleviating electric field concentration and reducing lateral area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

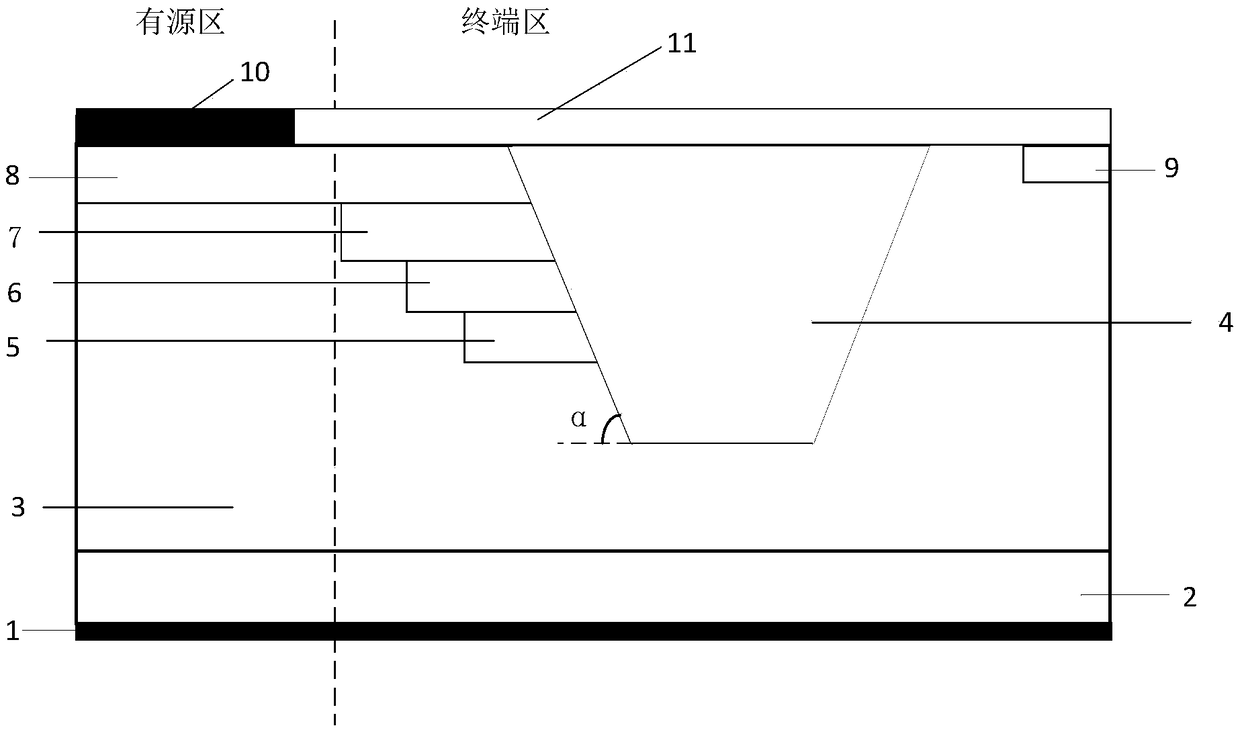

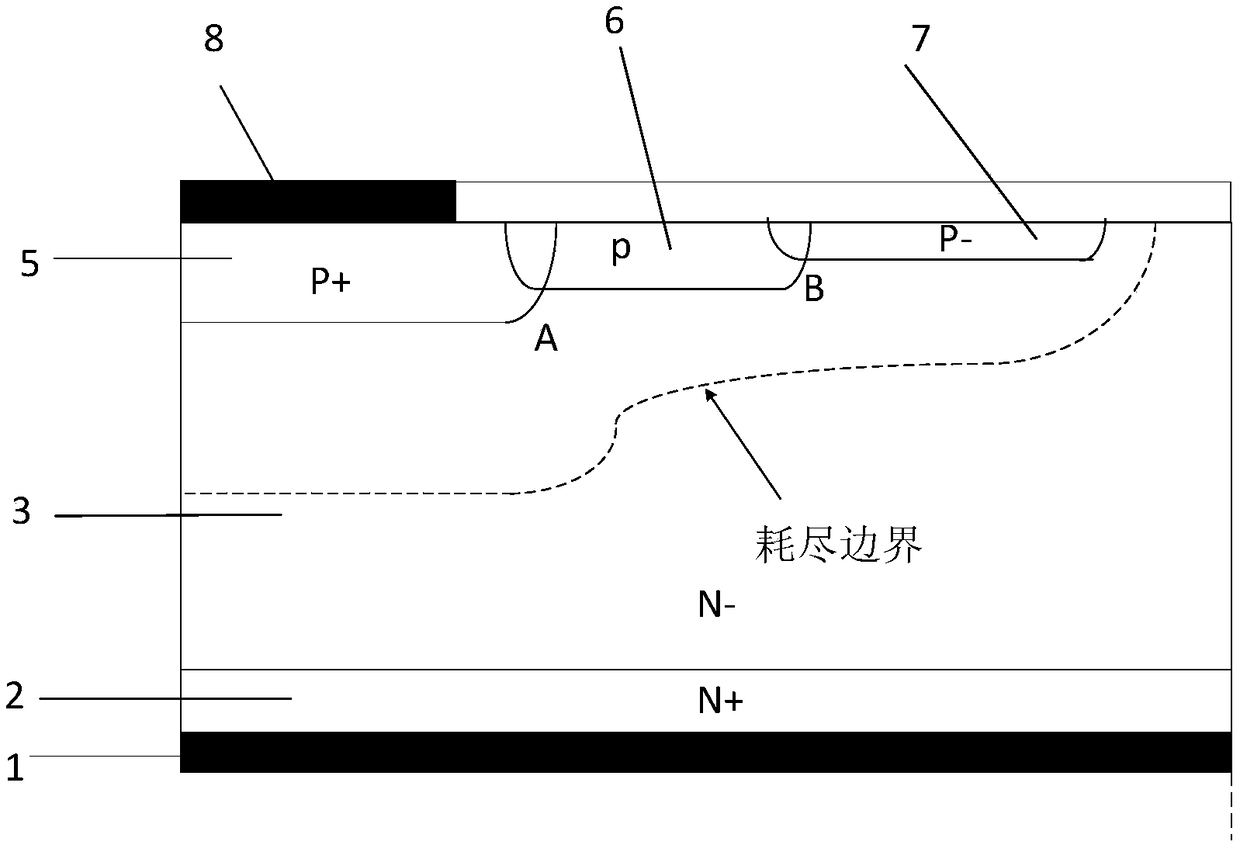

[0022] Such as figure 1 As shown, the power semiconductor device terminal structure of this example includes a metal drain electrode 1, a first conductivity type semiconductor heavily doped substrate 2, a first conductivity type semiconductor lightly doped drift region 3, and a field The oxide layer 11 is characterized in that the first conductivity type semiconductor lightly doped drift region 3 has a trench region 4, a first conductivity type semiconductor heavily doped region 9, a first implantation region 7, and a second implantation region 6. And the third implantation region 5; the upper surface of the trench region 4 is in contact with the field oxide layer 11; the first conductivity type semiconductor heavily doped region 9 is located on the first conductivity type semiconductor lightly doped drift region 3 and is far away from the device One end of the active region; the side surfaces of the first injection region 7, the second injection region 6 and the third injection...

Embodiment 2

[0035] Such as Picture 9 As shown, the structure of this example is based on Embodiment 1, and a buried layer 14 of a semiconductor of the first conductivity type is formed directly under the trench 4, which can reduce the electric field concentration at the corner of the trench and further improve the withstand voltage.

Embodiment 3

[0037] Such as Picture 10 As shown, the structure of this example is based on the embodiment 1, the trench 4 is dug into the body of the second conductivity type heavily doped region 4, which can eliminate the electric field spike at the corner of the trench 4 in the embodiment 1. Improve withstand voltage.

[0038] Semiconductor materials such as silicon carbide, gallium arsenide, indium phosphide or silicon germanium can also be used to replace bulk silicon when making devices.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com