High-voltage brushless direct-current generator structure

A DC generator, high-voltage technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of electrostatic interference, generator vibration, reliability (short life, etc.), to improve cooling efficiency, absorb vibration and shock, The effect of increasing the cooling area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

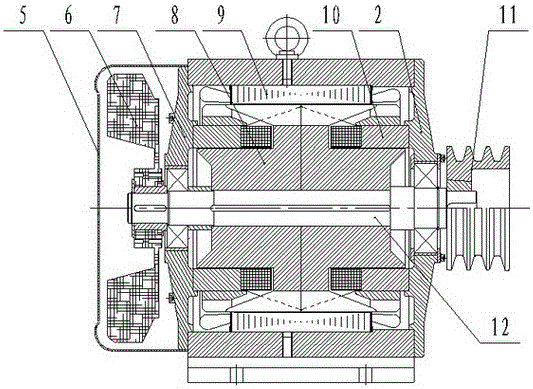

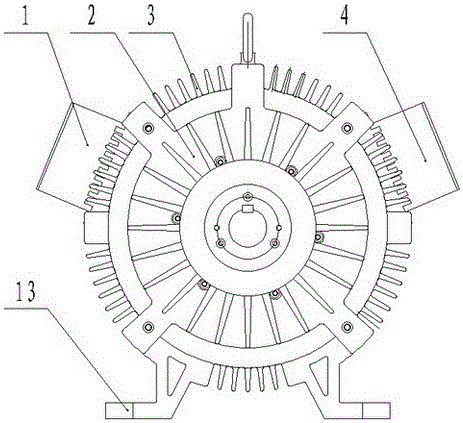

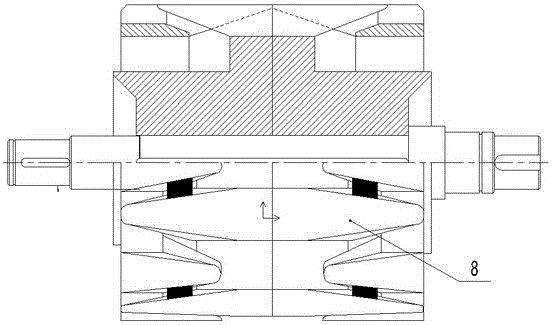

[0026] figure 1 As shown, one end of the heat dissipation shell 3 is connected to the front heat dissipation end cover 2, and the other end is connected to the rear heat dissipation end cover 7, and the front heat dissipation end cover 2 and the rear heat dissipation end cover 7 are installed with the heat dissipation shell 3 through screws; sealing measures are taken in between , the main purpose is to ensure that the internal live parts of the motor (including the stator 9 and the excitation assembly 10) are isolated from the outside; the stator 9 and the heat dissipation shell 3 are fixed as one, and there is a brushless Rotor 8; There are two excitation components 10, which are respectively fixed on the front cooling end cover 2 and the rear cooling end cover 7, the cooling fan 6 is installed on the outside of the rear cooling end cover 7, the fan guard 5 is placed on the outside of the cooling fan 6, and It is connected with the rear cooling end cover 7. There is a seali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com