LED chip production technology

A LED chip and production process technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of discoloration of the appearance of the metal layer, generation of pinch marks, and peeling off of the metal layer to achieve the effect of eliminating electrostatic interference and preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

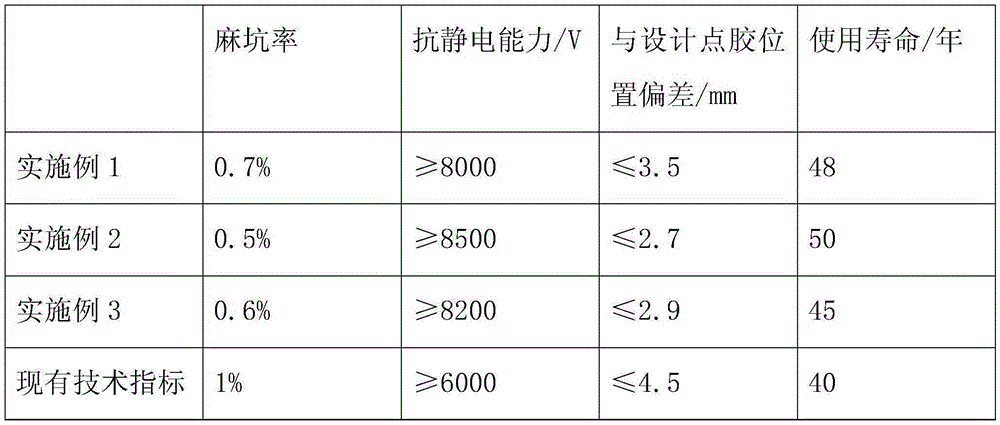

Examples

Embodiment 1

[0040] A kind of LED chip production technology, it is characterized in that, its step comprises:

[0041] (1) cleaning

[0042] Ultrasonic cleaning is used to clean the LED bracket. The cleaning parameters are: ultrasonic vibration frequency 20,000 Hz, time 15 minutes, drying after cleaning, constant temperature drying, temperature 75°C, time 30 minutes;

[0043] (2) Expansion film

[0044] Expander is used to expand the film bonded to the chip, and the chip is preheated before expansion. The preheating temperature is 50°C, so that the distance between the LED chips is stretched to 0.55mm. The operating parameters of the expander are: working air pressure 4Kg / cm2, the temperature is 25°C, after the expansion is completed, the LED chip is solidified;

[0045] (3) spines

[0046] Place the LED chip on the jig of the piercing table, place the LED bracket under the jig, and stab the LED chip to the corresponding position one by one with a needle under the microscope;

[0047...

Embodiment 2

[0070] A kind of LED chip production technology, it is characterized in that, its step comprises:

[0071] (1) cleaning

[0072] Ultrasonic cleaning is used to clean the LED bracket. The cleaning parameters are: ultrasonic vibration frequency 20,000 Hz, time 25 minutes, drying after cleaning, constant temperature drying, temperature 75°C, time 30 minutes;

[0073] (2) Expansion film

[0074] Expander is used to expand the film of bonded chips, and the chip is preheated before expanding. The preheating temperature is 50°C, so that the distance between LED chips is stretched to 0.60mm. The operating parameters of the expander are: working air pressure 4Kg / cm2, the temperature is 30°C, after the expansion is completed, the LED chip is solidified;

[0075] (3) spines

[0076] Place the LED chip on the jig of the piercing table, place the LED bracket under the jig, and stab the LED chip to the corresponding position one by one with a needle under the microscope;

[0077] (4) d...

Embodiment 3

[0100] A kind of LED chip production technology, it is characterized in that, its step comprises:

[0101] (1) cleaning

[0102] Ultrasonic cleaning is used to clean the LED bracket. The cleaning parameters are: ultrasonic vibration frequency 20000 Hz, time 30 minutes, drying after cleaning, drying at constant temperature, temperature 75 ℃, time 30 minutes;

[0103] (2) Expansion film

[0104] Expander is used to expand the film of bonded chips, and the chip is preheated before expanding. The preheating temperature is 50°C, so that the distance between LED chips is stretched to 0.75mm. The operating parameters of the expander are: working air pressure 4Kg / cm2, the temperature is 45°C, after the expansion is completed, the LED chip is solidified;

[0105] (3) spines

[0106] Place the LED chip on the jig of the piercing table, place the LED bracket under the jig, and stab the LED chip to the corresponding position one by one with a needle under the microscope;

[0107] (4)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com