High-precision compact AGV driving wheel assembly

A driving wheel, high-precision technology, applied in the direction of casters, wheels, electric components, etc., can solve the problems of many accumulated errors, increasing the structure size, reducing the transmission accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

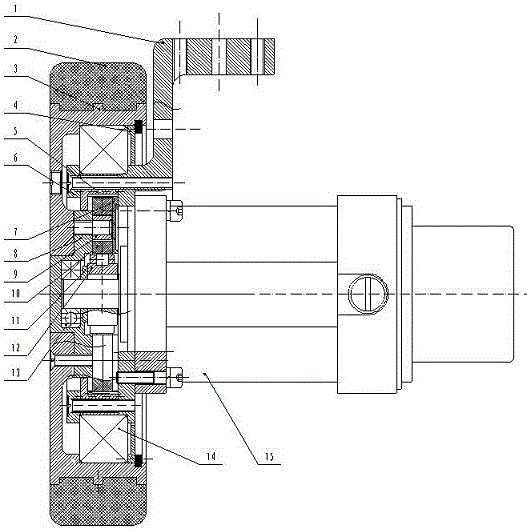

[0015] The purpose of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0016] The embodiment of the present invention is an RV speed reducer as a part of the embodiment, and the present invention can also be applied to a harmonic speed reducer.

[0017] The embodiment of the present invention is a light-weight structure with a single bearing supporting a smaller wheel body. The present invention can also be applied to a heavy-duty structure with multiple bearings supporting a larger wheel body.

[0018] The axially outer surface of the wheel body (3) made of metal material has a two-way texture closely combined with polyurethane rubber, and the polyurethane wheel surface (2) is co-cast on the axially outer surface of the wheel body (3). Invented wheel body (3) for drive wheels with a relatively high friction tread.

[0019] The present invention is connected with the AGV car body through the wheel frame (1)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com